Heat Treatment: Tempering

The word ‘tempering’ generally means acting as a counterbalancing force, moving an object (or a situation) away from the extremes, toward a more balanced state. The same principle applies to heat treatment: when we temper a metal part, we are adjusting the proportion of one mechanical property against another. Specifically, we are increasing ductility while simultaneously decreasing strength and hardness.

Tempering is most often performed after a metal piece has been seriously stressed through hardening or after normalizing. When a material is hardened (especially quench hardened, the most common method of hardening), it is in an unbalanced state. In metallurgical terms, we say the metal is unstable: its molecules would like to rearrange into a more stable structure, but the quench hardening process freezes them before they get the chance. Likewise, the process of normalizing takes the steel molecules through a phase transformation, leaving stresses in its wake. (For a longer discussion of phase transformations, check out our Introduction to Heat Treatment for Cast Parts.)

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Annealing

The heat treatment known as annealing encompasses a group of processing heat treatments. Unlike thermal processes that are used to improve the strength and wear resistance of a part (such as hardening heat treatments), processing heat treatments are used to prepare a workpiece for further manufacturing processes. Chiefly, this means improving a material’s responsiveness to machining or cold-working by restoring (and even enhancing) ductility.

After an annealing process, the part can be expected to go to the machine shop for additional subtractive manufacturing, or to a mill to be cold worked. In fact, annealing makes machining and cold working easier (even possible) by relieving internal stresses, reducing hardness, increasing ductility and toughness, and softening the material to make it more machinable and workable.

Tags: Processes, Metallurgy, Heat Treatment

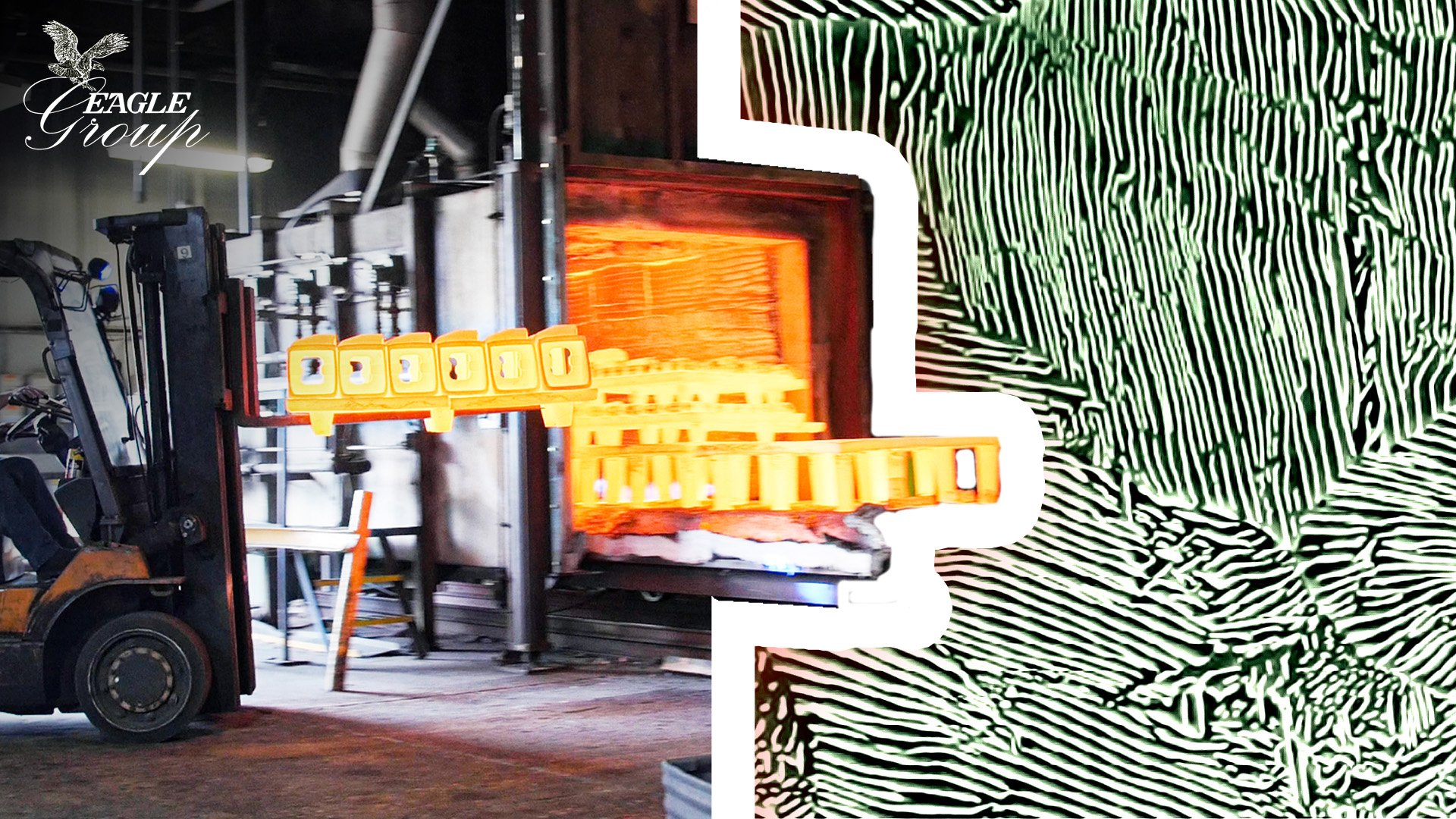

Heat Treatment: Quenching

Imagine a medieval blacksmith hammering a sword fresh out of the fire. With the weapon still red-hot, he dunks it in water. The water hisses and boils around the submerged steel as it turns color from glowing orange to grey. This iconic scene of rapidly cooling a workpiece is called quenching, or quench hardening, and is one of the oldest and most common heat treatment processes used to harden and strengthen common carbon steels. In modern metallurgy, superior corrosion resistance for most stainless steels is also an important property achieved through quenching.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Stress Relief

Internal stresses form naturally during many manufacturing processes. Machining, stamping and welding, for example, are common manufacturing methods that augment the amount of stress in a material’s fabric. And although stress build-up is a natural byproduct of these processes, too much of it leads very commonly to part distortion. Most of these stresses must therefore be removed before a part can be considered ready and safe to use. Thanks to heat treatment, these stresses can be relieved (without changing a part’s mechanical properties) through a thermal process known as stress relieving.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Hardening

Hardening a metal achieves much more than simply making it mechanically harder. It also improves strength, making the alloy more resistant to plastic deformation, and can aid with corrosion resistance. However, a harder metal is also often a more brittle metal. As such, hardening is usually just one part of a properly designed heat treatment plan.

Because hardening can be accomplished through numerous heat treatment strategies, it’s important to know what options are available to a casting customer, how the methods differ, and where hardening fits into the master plan.

In this article, we’ll explore the science and practice of hardening, and explain when conditions are appropriate for a particular hardening strategy. Whether you’re working with the Eagle Group or another metal manufacturer, hardening is an important step in manufacturing, so it’s good to know the basics.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Normalizing

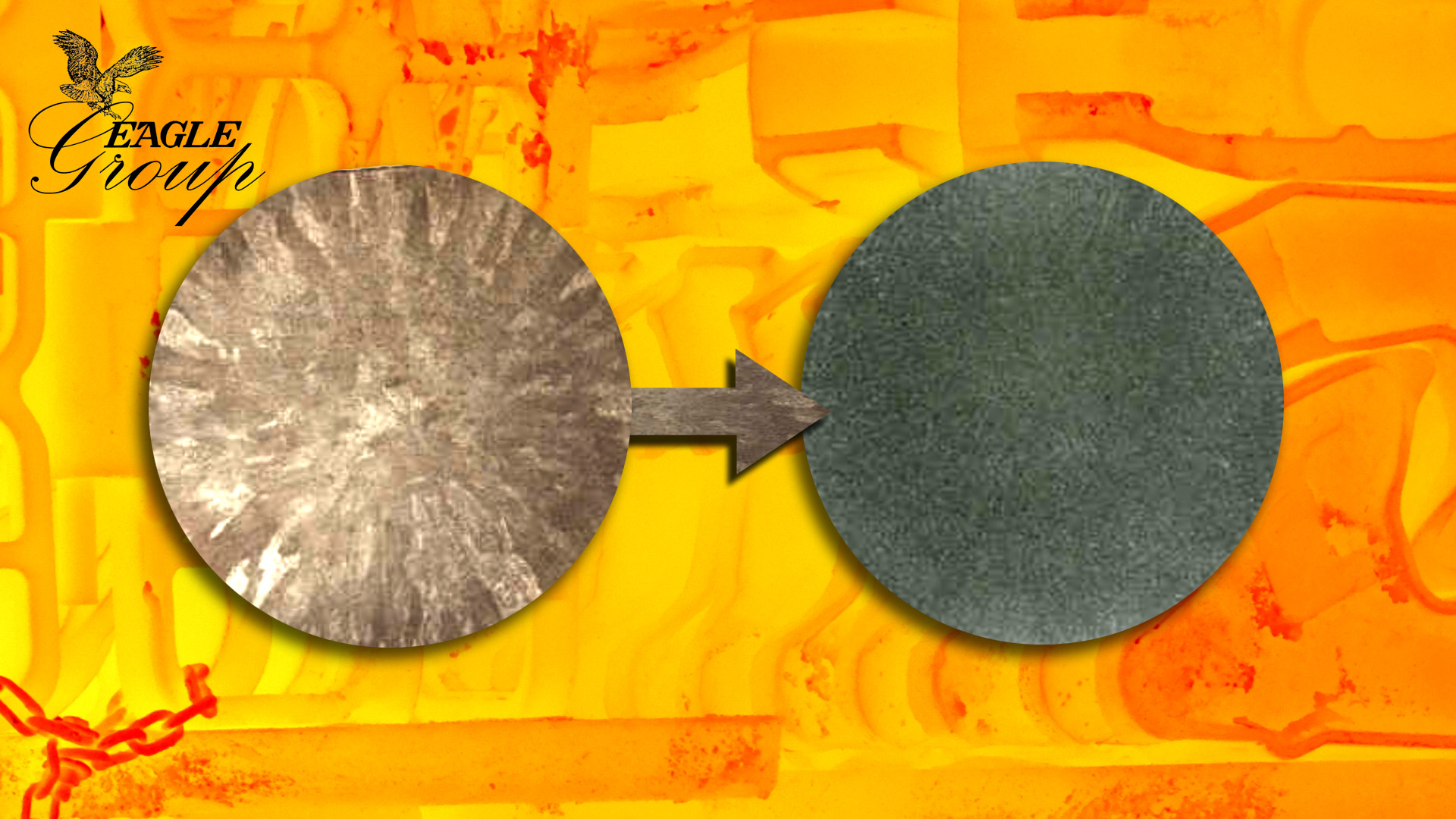

Normalizing is one of the most common heat treatments used in manufacturing carbon steel. It is a vital process to ensure that the mechanical and physical properties of a carbon steel workpiece are integrated and distributed uniformly across the material.

In steelmaking, material uniformity is achieved by carefully controlling a casting’s microstructure – specifically, its grains. Grains are distinct areas of crystal structures oriented in the same direction. Multiple grains together make up a metal’s structure. The goal of normalizing is to target these grains in order to even out the differences between them, resulting in a more mechanically stable product. It’s for this reason that the process is named as such: it ‘normalizes’, or homogenizes, grain size, shape, and orientation.

Tags: Processes, Metallurgy, Heat Treatment, Normalizing

Introduction to Metalcasting

This introduction to metalcasting provides a brief overview and history of the casting process, as well as an outline of common casting techniques in use today. The goal of this article is to give new manufacturers a better understanding of how metalcasting works and what steps are involved in producing cast products. By the end of the article, the reader should have a clear picture of the opportunities presented by metalcasting, and a sound appreciation for its potential as a modern manufacturing method.

Tags: Metalcasting, Processes, History

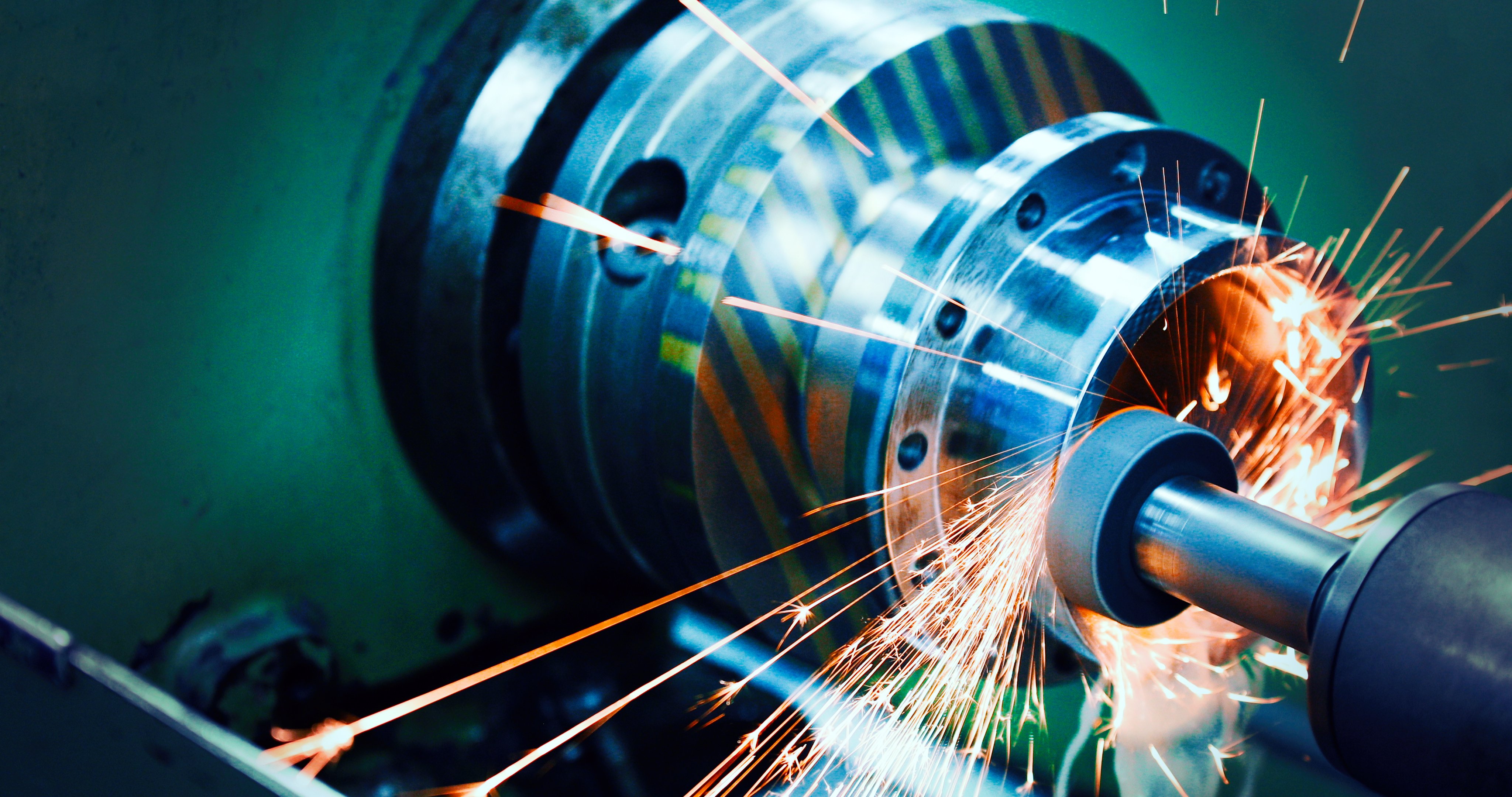

What Precision Machine Shops Do: Grinding

Grinding is a machining process using abrasive surfaces to remove material from metal workpieces. On the surface (pun intended) grinding may seem different than other machining processes, but it still works through chip formation and removal–just like sawing, milling, broaching and most other techniques. Grinding can produce surfaces conforming to rough or extremely close tolerances. Because of its versatility, grinding is used for simple gate removal in castings as well as advanced finishing processes like polishing and sharpening.

Tags: Processes, Machining, Eagle CNC, What Precision Machine Shops Do, grinding

What Precision Machine Shops Do: Broaching

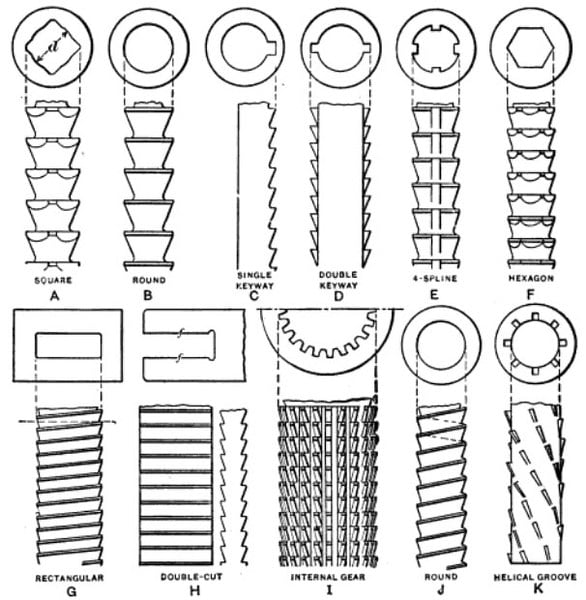

Broaching is a machining process using a cutting tool with teeth that increase in size from front to back. In many cases, an entire surface (or multiple surfaces) can be finished in a single pass with broaching. The technique is most often applied to finish holes, splines and flat surfaces.

Broaching is a relatively new machining process, developed in the 1850s with metal-specific applications. Originally, broaching was used to perform work on internal characteristics, like keyholes in pulleys and gears. During the 20th century, broaching was further developed for use in firearms, and subsequent developments have dramatically improved tolerances and made broaching more versatile for modern machine shops.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do, broaching

What Precision Machine Shops Do: Sawing

Sawing is one of the oldest cutting techniques in use today, and innovations have allowed the process to keep up with advances in material, tolerances and product complexity. By definition, sawing is cutting a narrow slit in a workpiece by moving a toothed or abrasive cutting tool against the surface. Sawing is often used to remove large sections of material without particular concern for tolerances, but modern CNC sawing machines can be used for finishing work as well.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do