Continuous Improvement in Investment Casting

This article is part of our series: Continuous Improvement at Eagle Precision

Continuous improvement is an ongoing effort to make incremental changes in a company’s processes that improve efficiency and quality. While the concept is fairly simple, many businesses find it challenging to sustain continuous improvement over the long term.

Continuous improvement is one facet of Lean Manufacturing, which is a set of tools used to maximize output and minimize waste. The meaning of ‘minimizing waste’ in manufacturing is a far-reaching term. Some examples include:

- Unused material reclamation and recycling

- Cutting down on energy and transportation costs

- Reducing wait times

- Minimizing product defects and returns

Tags: Lean Manufacturing, Eagle Precision, Robotics, Continuous Improvement

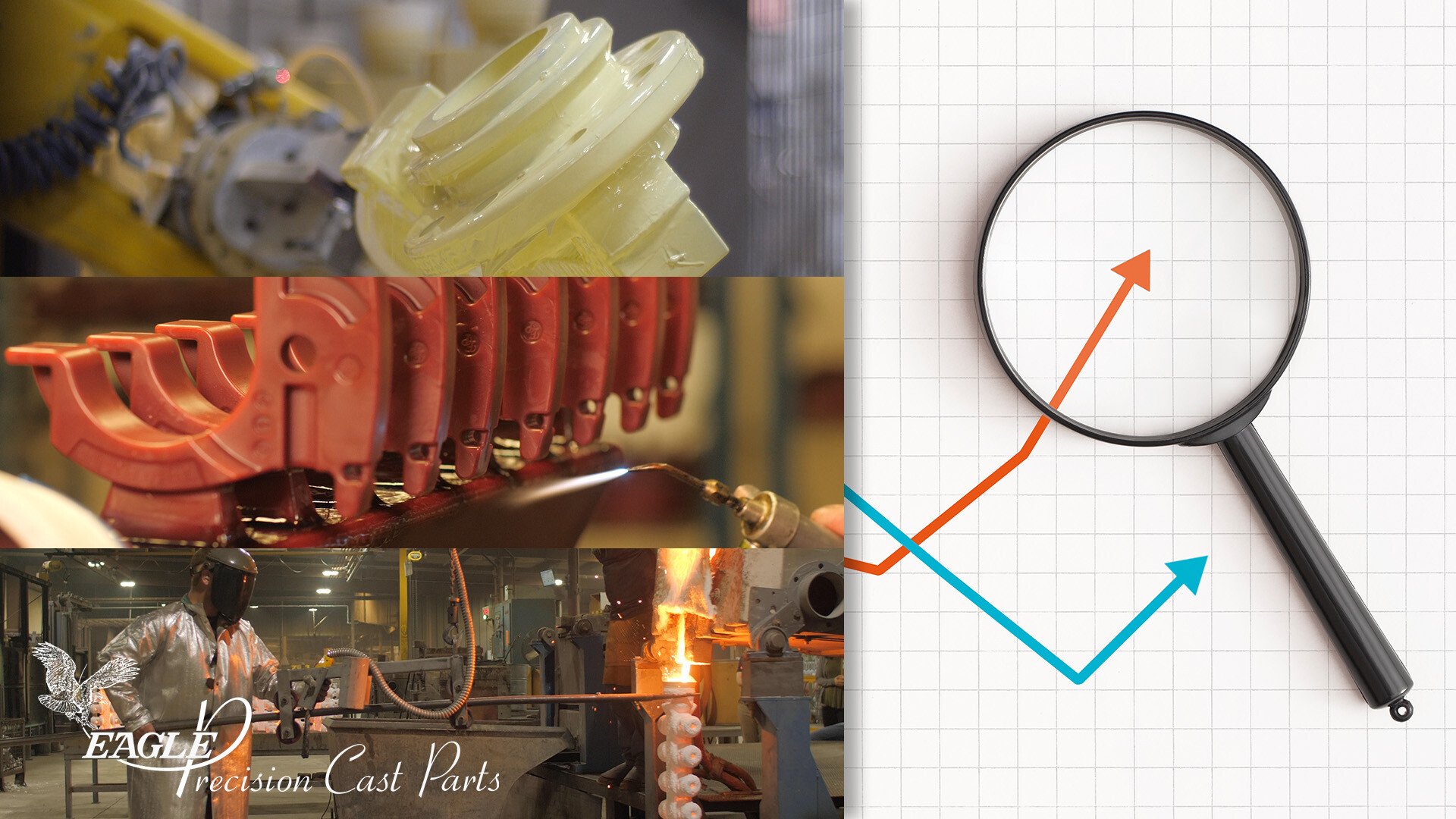

Robotics in Investment Casting

Our investment casting foundry, Eagle Precision, makes use of robotics in two steps of the casting process. We started with a robotic dipping cell and expanded into two, followed by a third robotic cell that specializes in after-cast grinding. While robotic cells like these do require a large up-front investment, we’re already seeing company-wide benefits resulting from our use of robotics in investment casting.

Robots are becoming more and more common throughout the manufacturing industry, and investment casting is no exception. According to John Scott, VP of Sales at Buntrock Industries, the investment casting industry is seeing increased demand for robotics for three reasons: “lack of workforce availability, desire for increased process control and productivity, and improved health and safety.”

Tags: Investment Casting, Eagle Precision, Robotics, grinding

Improving Casting Production with In-House Robotics Expertise

In many ways Dakota Hanson (above) is a typical Young Millennial: he's an avid Tik Tok fan, spends his spare time playing Call of Duty, and has a job working with cutting-edge technology. However, unlike many members of his generation, Dakota's workplace is more than a laptop and a WIFI connection. As an Engineering Technician at Eagle Alloy (a shell molding facility in Muskegon, MI) Hanson specializes in programming robotic cells that play an integral role in the manufacturing process.

In fact, Eagle Alloy has a growing number of employees whose job descriptions include programming and operating robotic cells. Through a continuing education program led by robotics manufacturer ABB, Eagle Alloy has been able to provide its in-house team with manufacturing robotics expertise, further improving the company’s response time and resilience.

Tags: Eagle Alloy, Capabilities, Technology, Robotics, grinding, Employees

The Rise of Robotics in Metalcasting and Machining

The use of robotics in manufacturing, including metalcasting and machining, has grown steadily since the 1970s. Industrial automation increasingly relies on robotics as a way to improve efficiency and replace monotonous, repetitive human tasks.

Robots are used for a wide variety of tasks in manufacturing, from transportation to assembly. In metalcasting and machining, robots can be used to complete nearly any programmable task, from dipping and pouring to grinding and milling.

Tags: Eagle Alloy, Eagle Precision, Robotics