Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

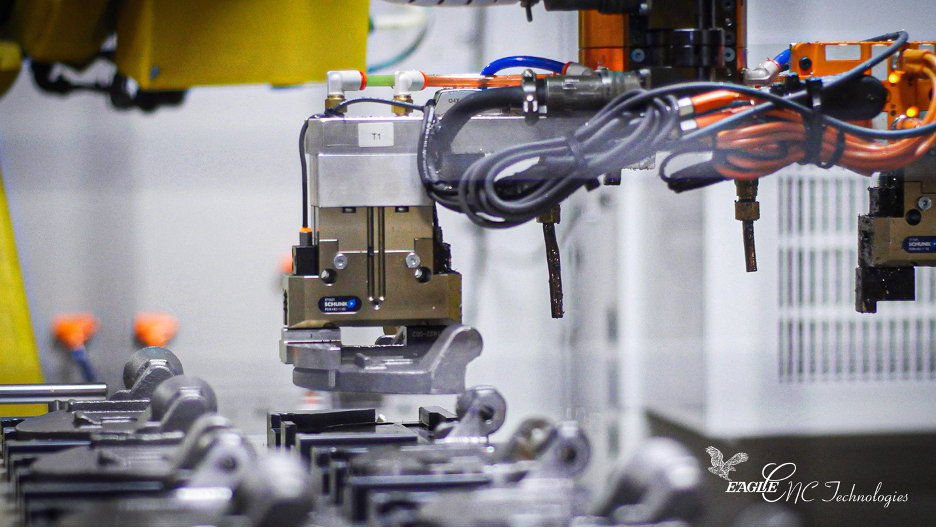

Improving Casting Production with In-House Robotics Expertise

In many ways Dakota Hanson (above) is a typical Young Millennial: he's an avid Tik Tok fan, spends his spare time playing Call of Duty, and has a job working with cutting-edge technology. However, unlike many members of his generation, Dakota's workplace is more than a laptop and a WIFI connection. As an Engineering Technician at Eagle Alloy (a shell molding facility in Muskegon, MI) Hanson specializes in programming robotic cells that play an integral role in the manufacturing process.

In fact, Eagle Alloy has a growing number of employees whose job descriptions include programming and operating robotic cells. Through a continuing education program led by robotics manufacturer ABB, Eagle Alloy has been able to provide its in-house team with manufacturing robotics expertise, further improving the company’s response time and resilience.

Tags: Eagle Alloy, Capabilities, Technology, Robotics, grinding, Employees

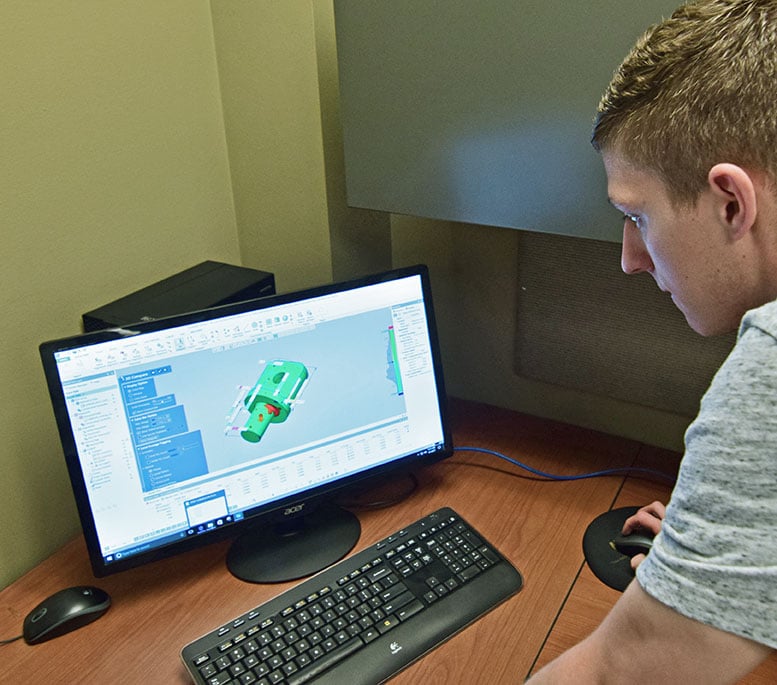

Designing Cast Products: 3D Modeling and Solidification Simulation Software

The rise of CAD/CAM software largely defines the current era of manufacturing. While blueprints and dimensional charts are still widely used as reference guides, modern manufacturers rely on software to design prototypes and simulate casting processes. One of the first steps in the cast part development process is to create a 3D model. From there, engineers can improve the part shape, simulate a variety of casting processes and materials, and troubleshoot difficult manufacturing scenarios.

When done right, CAD/CAM software enables foundries to solve all the problems of casting in the virtual world, before pouring any metal. The results are cost savings for the customer, time savings for everyone, and reduction of overall waste.

Tags: Product Design, Development, Capabilities, Inspection, Product Development, Technology, CAD/CAM

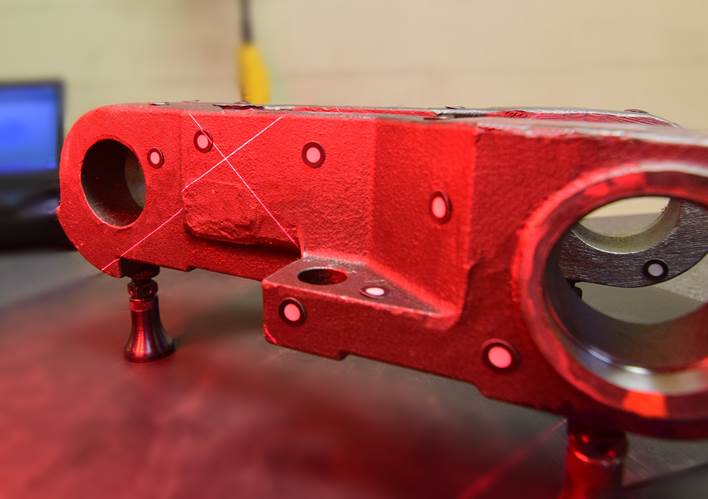

How Eagle Alloy's Handheld Laser Scanner Leads to Better Cast Products

Product development processes vary widely from foundry to foundry. The Eagle Group's Product Development blog series aims to highlight practices used by leading foundries that prioritize quality in every part they produce.

One product development practice that sets Eagle Alloy apart from other shell molding foundries is their use of a handheld laser scanner for inspection and dimensional reporting. This technology greatly improves the accuracy of dimensional reports, and makes it easier for customers to verify that new parts meet their requirements.

Tags: Metrology, Product Design, Development, Inspection, Product Development, Technology, 3D Scanning