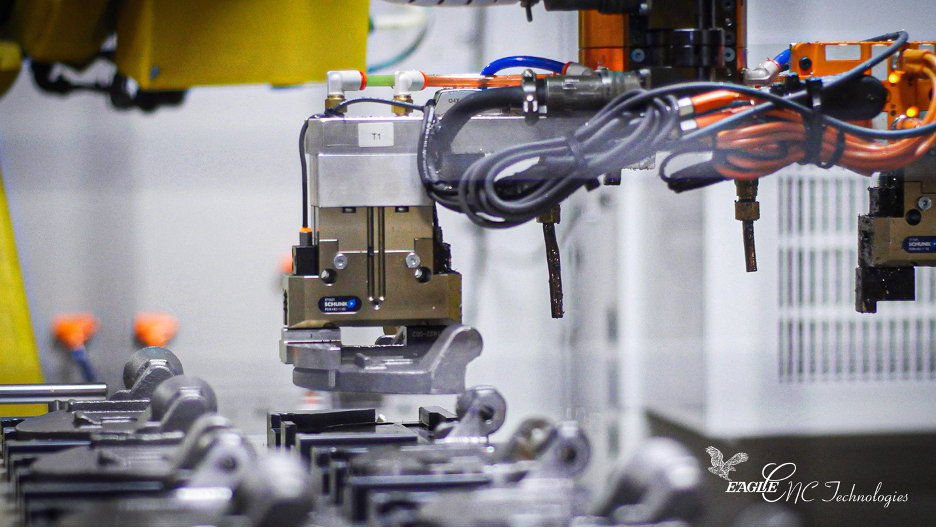

Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

Think Like an Owner: How ESOP Builds Innovation and Workforce Empowerment

ESOP is a way to transfer company ownership from one generation to the next—in many cases, this transfer happens when the original owners sell their stake in the company to their own employees. ESOP stands for Employee Stock Ownership Plan, but the acronym hardly conveys the potential of this empowering ownership model. That’s because ESOP is more than just a financial structure—it has the potential to shape company culture, fueling innovation, driving accountability and making an appreciable difference in the quality of customer relationships.

Our slogan at Eagle Precision is “Think Like an Owner,” which is a direct reference to our ESOP structure, and aims to boost awareness among our employees of the benefits we all share. Our employees are our company owners, and adopting that mentality has already led to a slew of innovations and improvements in our daily operations.

Tags: American Manufacturing, Eagle Group Values, Eagle Precision, ESOP, Employees, Human Resources

5 Reasons American Manufacturing of Cast Products Can’t Be Replaced

This blog was updated on July 16, 2024.

You might have heard from politicians, journalists and even investors that American manufacturing is on the decline. There have been claims that globalization has weakened domestic manufacturing (1) and that businesses will continue outsourcing to low-cost countries. Some people even go so far as to say that manufacturing jobs won't be an option within a generation or two. But you know what? They’re wrong.

Those who currently work in the American manufacturing industry understand that this outlook—that manufacturing is on the decline—is far from the truth. In reality, an increasing number of American manufacturers are coming back to the U.S. from lower cost countries. They recognize the cost advantages diminish as other risks associated with low-cost countries increase.

Manufacturing in the U.S. reduces risks significantly and is an attractive option for keeping operations domestic, with numbers to back it. The United States currently has a thriving manufacturing sector, with an annual output of more than $4 trillion (2). Manufacturing in the United States is thriving and will be for a long time to come.

Below are five key reasons why American manufacturing of cast products can’t be replaced.