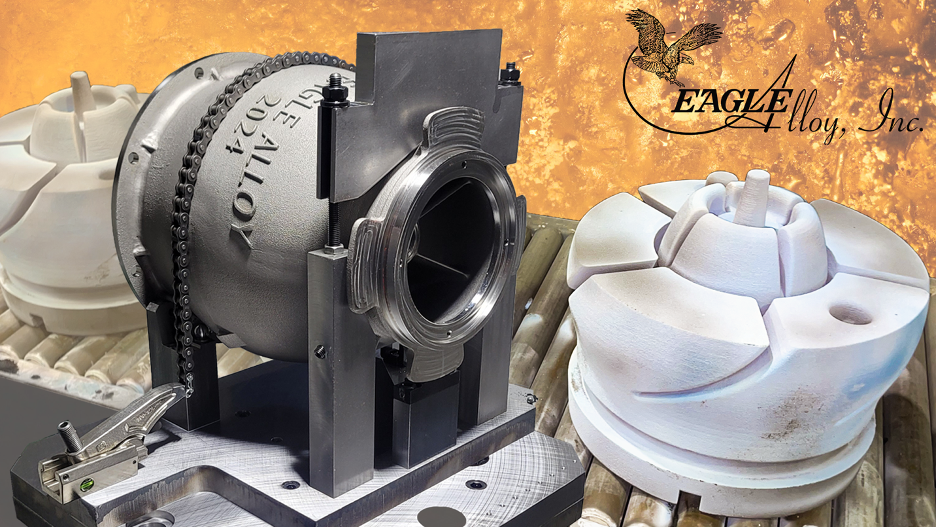

Rapid Prototyping for Castings: How Eagle Alloy Delivers High-Quality, Low-Volume Cast Parts on Tight Timelines

When time and flexibility are top priorities, rapid prototyping for castings offers manufacturers a fast-track route to producing complex cast parts in small quantities. At the Eagle Group, this advanced approach supports both prototype development and low-volume production, helping customers refine designs, verify performance, and move from concept to production quickly without the long lead times associated with permanent tooling.

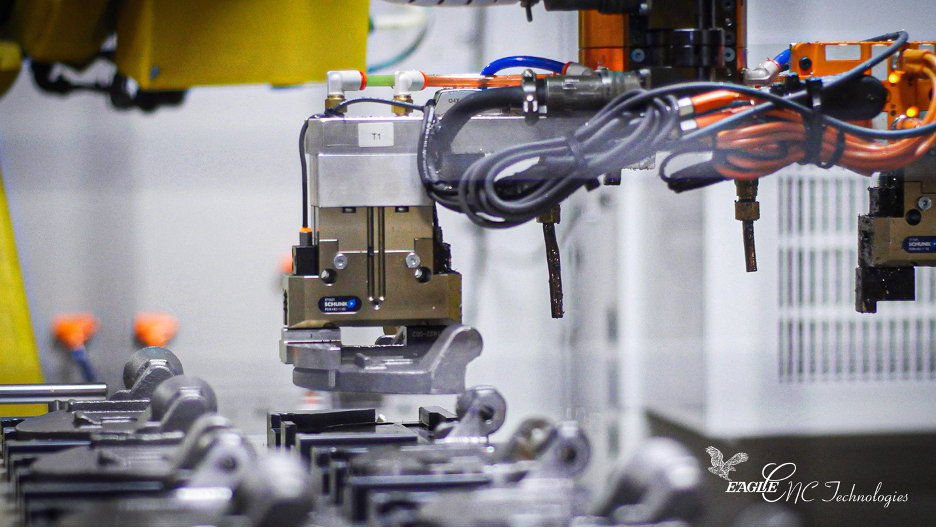

Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

Think Like an Owner: How ESOP Builds Innovation and Workforce Empowerment

ESOP is a way to transfer company ownership from one generation to the next—in many cases, this transfer happens when the original owners sell their stake in the company to their own employees. ESOP stands for Employee Stock Ownership Plan, but the acronym hardly conveys the potential of this empowering ownership model. That’s because ESOP is more than just a financial structure—it has the potential to shape company culture, fueling innovation, driving accountability and making an appreciable difference in the quality of customer relationships.

Our slogan at Eagle Precision is “Think Like an Owner,” which is a direct reference to our ESOP structure, and aims to boost awareness among our employees of the benefits we all share. Our employees are our company owners, and adopting that mentality has already led to a slew of innovations and improvements in our daily operations.

Tags: American Manufacturing, Eagle Group Values, Eagle Precision, ESOP, Employees, Human Resources

Eagle Alloy on the High Seas: Our American Bureau of Shipping (ABS) Certification

Recently, Eagle Alloy squared off against the demanding technical requirements and thorough audits of the American Bureau of Shipping’s “Type Approval” certification. Through this process, we demonstrated our commitment to producing marine-grade castings that meet the highest standards for safety and reliability in the maritime industry, as well as our willingness to go deeper in our readiness to provide uncompromising castings to the marine industry.

Tags: Certification, ABS, American Bureau of Shipping, Quality

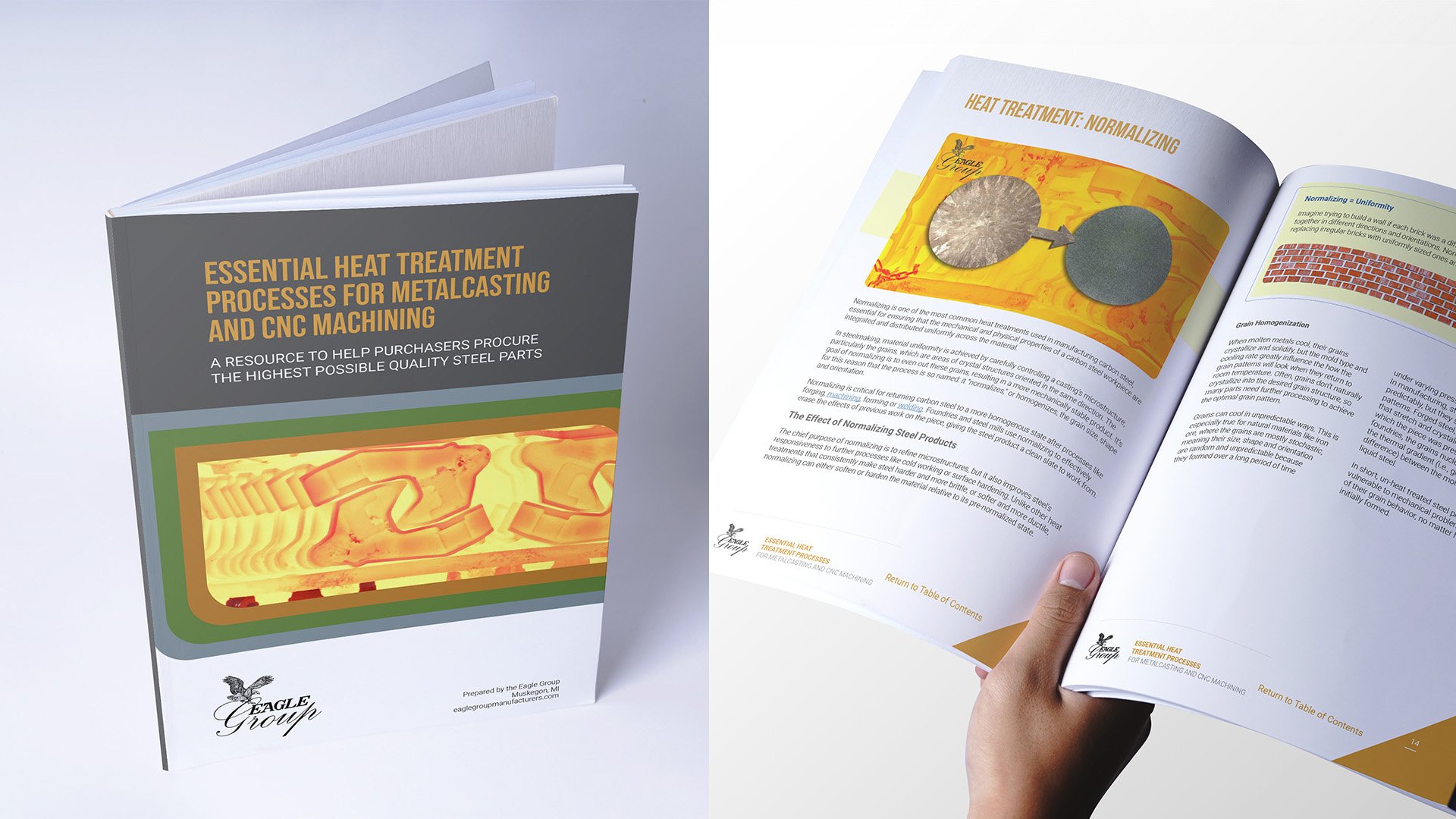

New Ebook: Heat Treatment Processes for Metalcasting and CNC Machining

The latest resource from the Eagle Group provides a comprehensive introduction to heat treatment in metalcasting and CNC machining.

This 40-page guide is available as a free download and is designed for manufacturing professionals, purchasers and engineers looking to deepen their understanding of heat treatment. It explores the role of heat treatment in enhancing the quality of cast and machined steel parts, ultimately helping purchasers procure the highest possible quality steel parts.

Tags: Heat Treatment

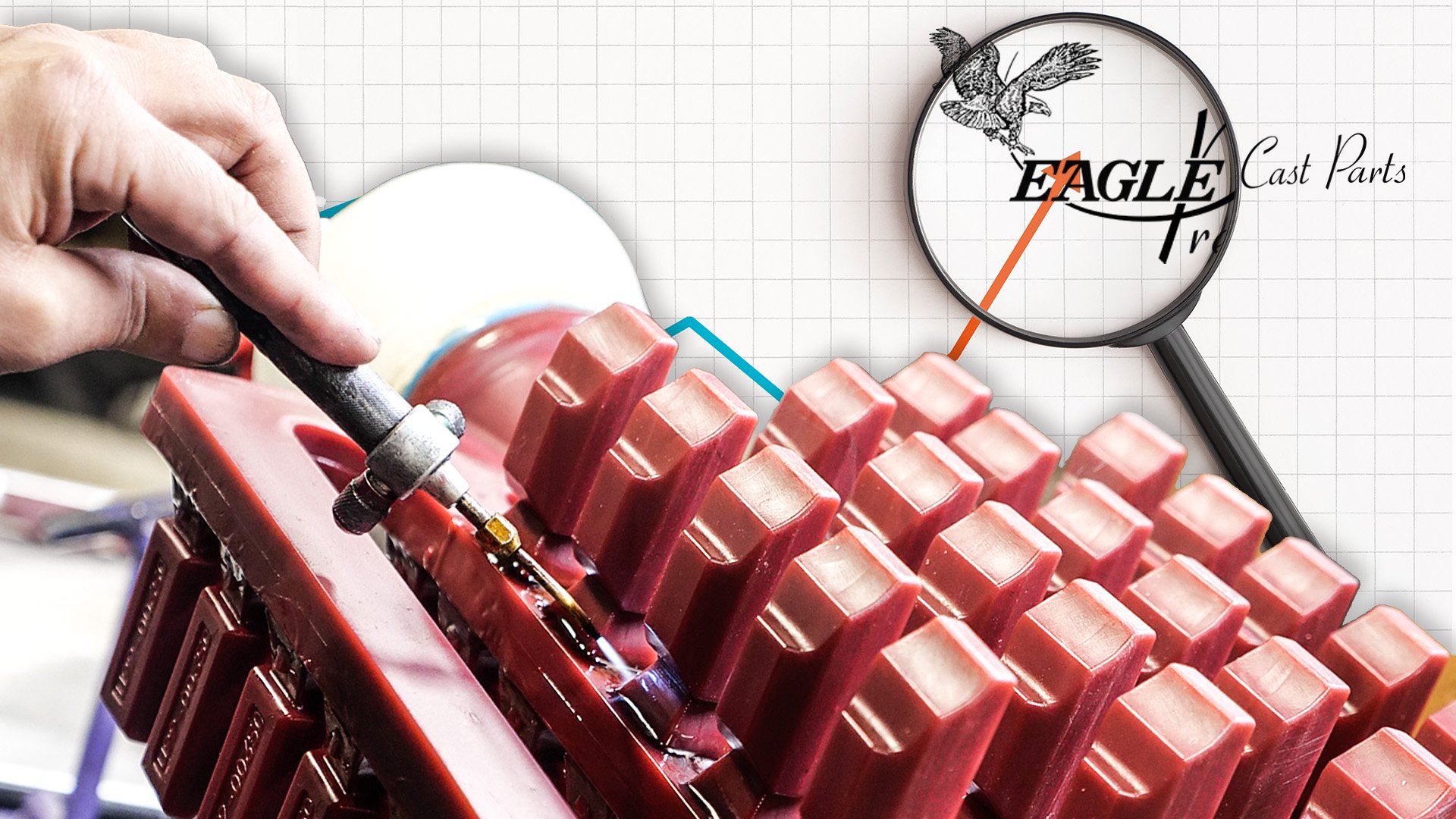

Continuous Improvement at Eagle Precision: Optimizing the Investment Casting Wax Room

This article is part of our series: Continuous Improvement at Eagle Precision

The wax room is at the heart (and start) of our investment castings. By injecting the wax room with fresh ideas, we’ve been able to greatly improve our pouring efficiency, leading to higher production yields, less downtime, reduced remelting rates, and faster delivery times.

Tags: Lean Manufacturing, Investment Casting, Eagle Precision, Continuous Improvement

Michigan Manufacturers Honor Veterans by Reviving a Sunken Patrol Boat

Collaboration Between Casting and Machining to Re-Engineer a Lost Component of a Vietnam-Era Patrol Boat

Muskegon-based manufacturers Eagle CNC and Eagle Alloy put their capabilities to the test when they set out to replicate a key component of a Vietnam-era patrol boat as a steel casting. For the team behind the casting, this project is about more than fixing a boat; it’s about preserving history, honoring the legacy of those who served and sacrificed, and ensuring their stories continue to be told for generations to come.

Tags: Eagle Alloy, CNC Machining, Eagle CNC, 3D Scanning, Reverse Engineering, 3D Printed Molding

The Heart of the Foundry: Celebrating the Career of Michigan Casting Trailblazer Dave Fazakerley

Dave Fazakerley, Eagle Alloy President and Chief Operating Officer, has played a central role in shaping the company since its early days. Over the course of his career, he has helped guide Eagle Alloy’s growth, build its operations, and foster a culture of quality and innovation—contributions that have helped the company become a recognized leader in the steel casting industry.

New Article in Modern Casting Magazine: Modular Automation at Eagle Precision

Automation in investment casting is often seen as the domain of large-scale foundries, with a common perception that it requires major capital investment, significant floor space, and rigid shop-floor layouts. But what if there were a way to bring the benefits of robotic automation to foundries of any size?

Tags: Eagle Precision, Capabilities, Equipment

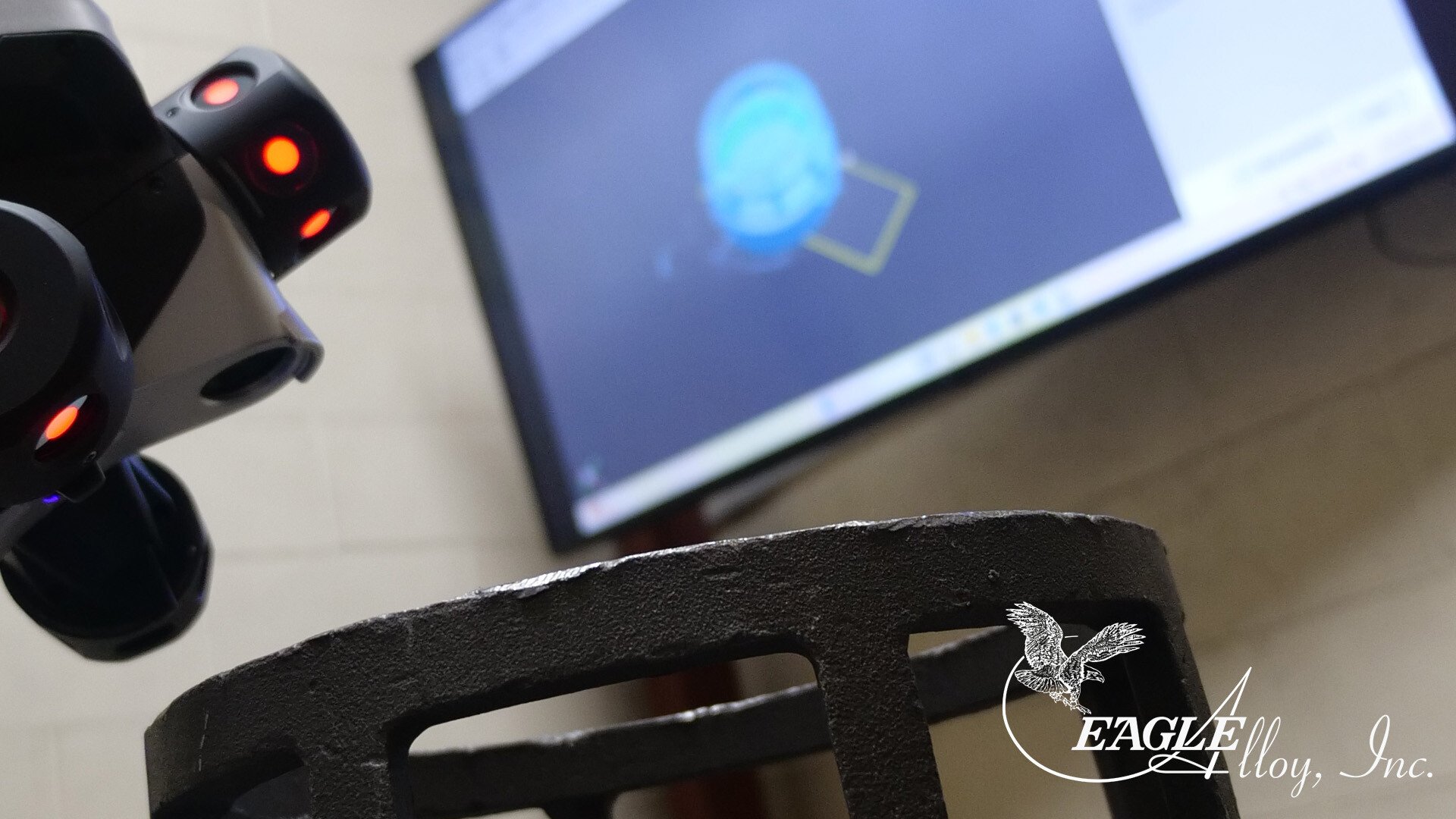

Beyond Quality Control: How Eagle Alloy’s Keyence WM-6000 Boosts Foundry Capabilities

The Eagle Group realized early on the value of 3D scanning for manufacturing. Eagle CNC, Eagle Precision and Eagle Alloy all utilize 3D scanning systems that optimize our capabilities not just for inspection, but also for reverse engineering and prototyping. For us, scanning is an integral part of the casting process.

That’s why Eagle Alloy has upgraded its Keyence scanner several times to stay ahead of the curve. Our latest model, the WM-6000, helps our shell-mold foundry deliver even more precise, reliable castings for our customers.

Tags: 3D Scanning