Aluminum Casting vs. Steel Casting: Choosing the Right Alloy for Your Cast Products

In modern metalcasting, steel and aluminum are two contenders for the top material of choice. Thousands of manufacturers around the world rely on both metals to produce strong, light and corrosion-resistant metal parts and products.

You'll find hundreds of different grades and alloys for both steel and aluminum, and each has its specific advantages and disadvantages. For this comparison, we'll focus on differences between aluminum and steel alloys in general, rather than zooming in on differences between specific alloys.

Tags: Metalcasting, Machining, Aluminum Casting, Aluminum, Materials

Casting Aluminum: Comparison of Methods

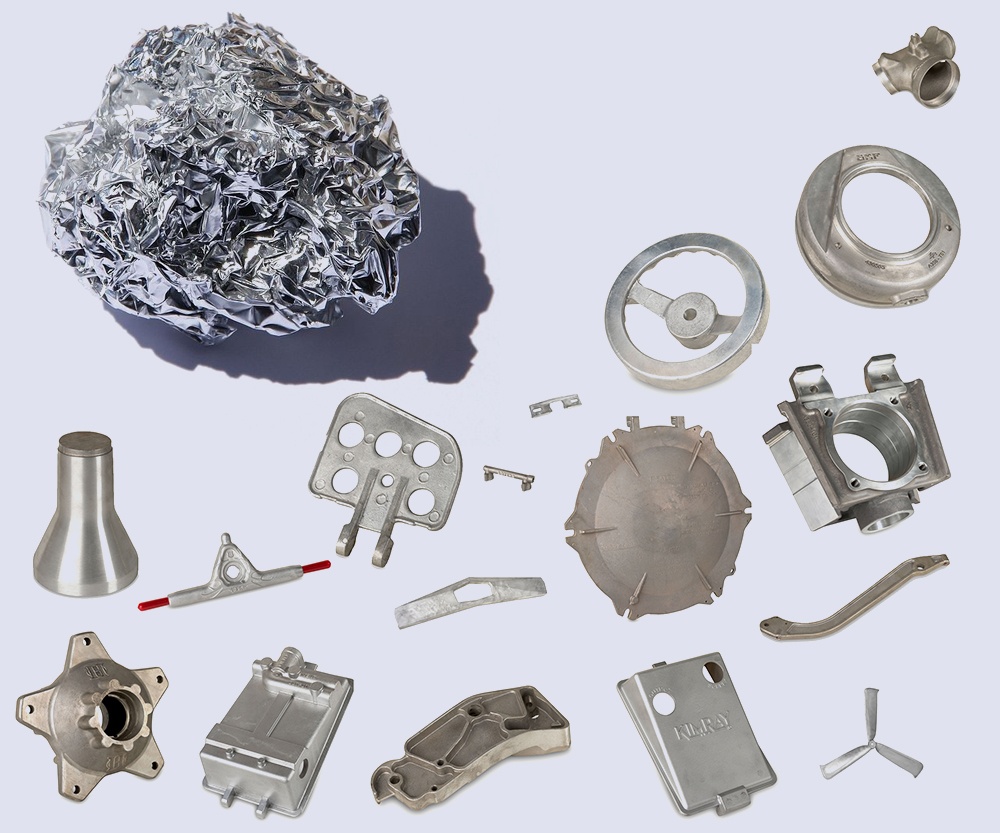

Aluminum can be shaped through a wide variety of process, including:

- Casting

- Extrusion

- Forging

- Rolling

For any type of metal, casting is arguably the most versatile of all of the forming processes, and results in the greatest variety of parts. In fact, the US Department of Energy estimates that over 90% of all manufactured goods contain metal cast products.

The same casting techniques used for other metals can be applied to aluminum, but some of the most popular methods used with aluminum are permanent mold casting, greensand casting and die casting.

Tags: Metalcasting, Processes, Aluminum Casting, Aluminum, Eagle Aluminum

New Eagle Group Resource Introduces Aluminum to Manufacturers

Eagle Aluminum Cast Products, Inc. recently published an ebook offering insight into manufacturing with aluminum.

Manufacturing with Aluminum: History, Forming Techniques and Best Practices draws on decades of experience, taking a holistic approach to aluminum manufacturing. Weighing in at just under 25 illustrated pages, the ebook aims to fill a gap between online resources and textbooks. According to Jim Smith, Technical Manager at Eagle Aluminum, “We want to make sure anyone curious about aluminum can get all the basic information they need, without searching all over the Internet or going back to school.”

Tags: Manufacturing, Aluminum Casting, Aluminum, Eagle Aluminum, Press Release, News

Aluminum Casting in Practice: A Case Study of Cast Aluminum Fan Blades

A major manufacturer of ventilation systems contacted Eagle Aluminum Cast Products, Inc. when demand was growing and they were ready to make a change.

The customer had already been producing 48” fan blades for agricultural use through green sand casting, but they’d outgrown that method. Demand projections suggested that permanent mold casting would yield lower per-part costs, with the added benefit of greater consistency.

Years later, EACP still produces fan blades for the customer through the process of permanent mold casting. Demand has increased even more, and product offerings have become more diverse. Read on to learn how EACP handles the design, production and delivery of this cast aluminum fan blade.

Tags: Aluminum Casting, Aluminum, All About Al, Case Study, Eagle Aluminum

All About Al: Choosing the Right Aluminum Alloy

In manufacturing, aluminum is rarely pure. Instead, manufacturers form alloys that dramatically increase aluminum’s strength and stiffness, while maintaining its other desirable properties. Both professionals and non-professionals often make comparisons between aluminum and steel, because the two metals are both used for such a wide variety of products.

But comparing aluminum to steel is a bit like comparing apples to oranges: steel is already an alloy, while aluminum is an element. Carbon steel, a basic steel alloy, is composed of iron (Fe) and carbon (C). Pure aluminum, despite its many winning properties, is too soft and not strong enough for most industrial applications. But aluminum alloys can be thirty times stronger than pure aluminum, and regularly exceed steel in strength-to-weight ratios.

Tags: Processes, Aluminum Casting, Aluminum, All About Al, Metals

All About Al: Aluminum's Winning Properties

Recently in our All About Al blog series we discussed aluminum's history and origins. Now we're getting deeper into why aluminum is the perfect material for manufacturing such a wide range of products.

Aluminum owes its versatility in manufacturing to a unique set of properties. These include:

- Low melting temperature

- Excellent malleability

- Light weight

- Corrosion resistance

Tags: Aluminum Casting, Aluminum, Materials, All About Al

All About Al: Crash Course in Aluminum History

Aluminum is the third most common element on our planet. It’s by far the most abundant metal, and it’s also one of the most versatile.

Aluminum is light, strong, flexible and corrosion resistant. It can also be shaped relatively easily, in both a solid and molten state, and can be stamped to widths thinner than the human hair.

You’ll find aluminum in everything from buildings to cars, from Pepsi cans to laptops, and from power lines to bullet trains. But where does this one-of-a-kind metal come from, and how did it get to be so widely used?

Tags: Metalcasting, Aluminum Casting, Aluminum, Materials, All About Al