Learn to Speak Our Language: Metalcasting & CNC Machining Jargon

Metal manufacturing professionals are a close-knit community, and just like any specialized group, we've developed our own way of speaking. To outsiders, many of whom are our friends, family and customers, metalcasting & machining lingo might seem like another language entirely. Here, we aim to demystify metalcasting & machining jargon so anyone can join the conversation.

Tags: Metalcasting, Glossary, CNC Machining

Ebook for Manufacturers: Metalcasting & CNC Machining Process Guide

Tags: Metalcasting, Machining, CNC Machining

Introduction to Metalcasting

This introduction to metalcasting provides a brief overview and history of the casting process, as well as an outline of common casting techniques in use today. The goal of this article is to give new manufacturers a better understanding of how metalcasting works and what steps are involved in producing cast products. By the end of the article, the reader should have a clear picture of the opportunities presented by metalcasting, and a sound appreciation for its potential as a modern manufacturing method.

Tags: Metalcasting, Processes, History

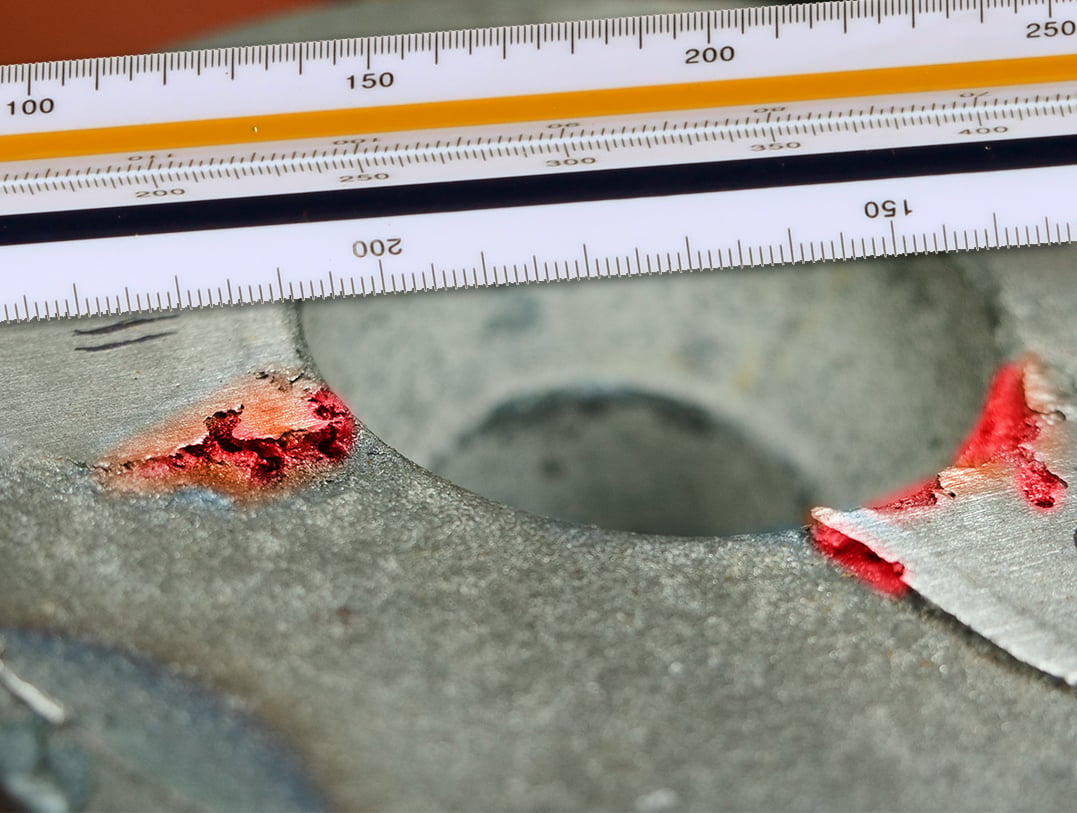

Understanding Casting Defects: When Is a Casting Returnable?

Metalcasting is a modern manufacturing industry, and cast products are utilized in 90% of durable goods, from lamp posts to space shuttles. Still, no casting is perfect. Even with recent innovations in simulation and process technology, nearly every cast product will contain some level of defect. A clear understanding of casting defects is vital for any casting customer, as it helps guide realistic expectations when working with a casting facility.

While experienced casting facilities are skilled in finding a balance between cost and quality, purchasers should be closely involved in determining admissible levels of defects in deliverable products.

Tags: Metalcasting, Casting Defects, Defects

5 Ways to Tell if Casting Is the Right Manufacturing Process for Your Products

Modern metal manufacturing offers a wide range of choices to bring designs into reality. Metalcasting has been around for millennia, and it's undergone its fair share of innovation over the years. Casting facilities can now handle almost any alloy, and can cast intricate designs with complex inner cavities that wouldn't have been possible even a few decades ago.

Tags: Metalcasting, Manufacturing, Fabrication to Casting, Fab-Casting

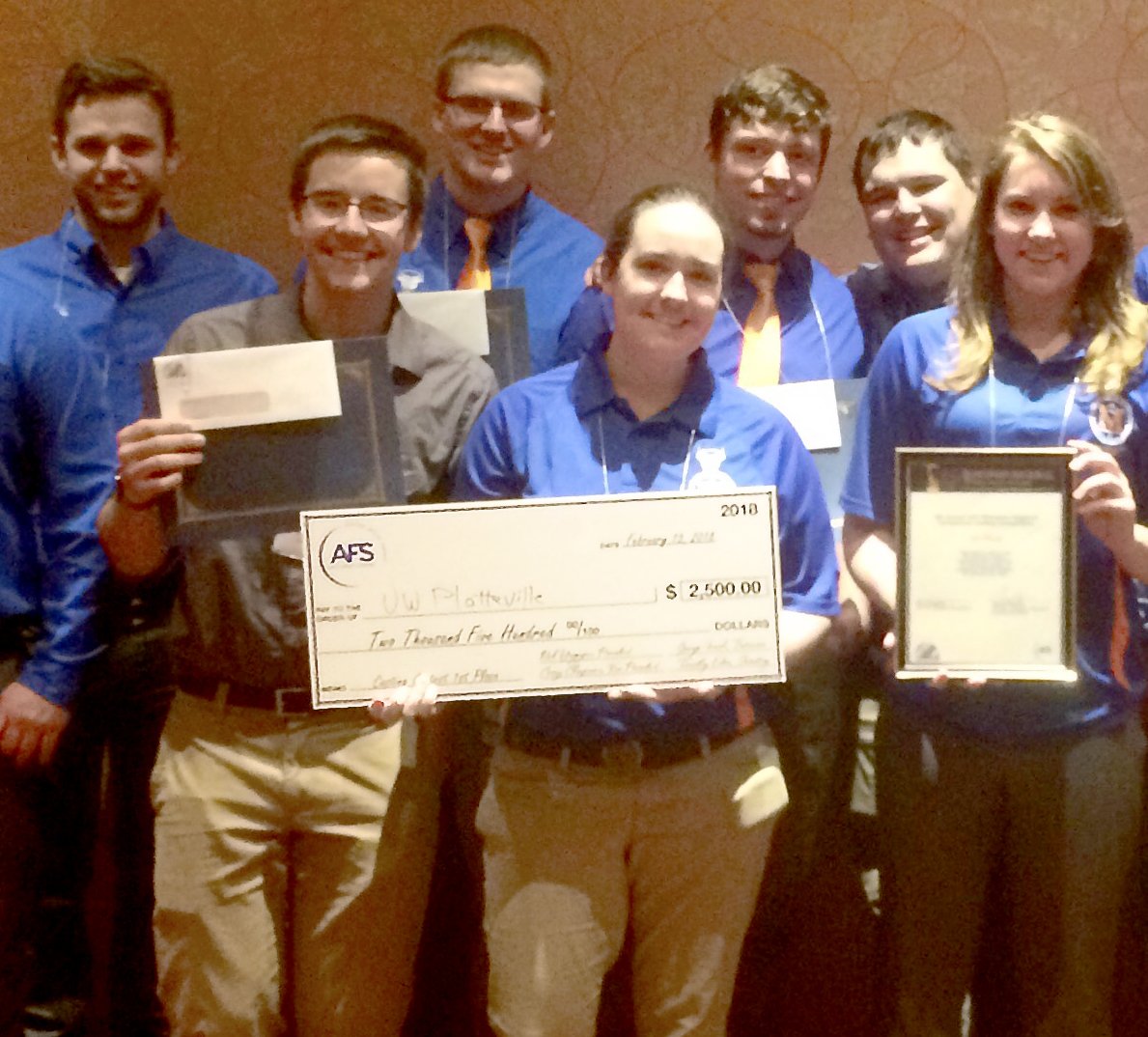

Coming Soon: AFS Regional Student Casting Competition

Forget about the Rose Bowl–this year's college competition to watch is coming up in February!

The AFS Wisconsin Regional Invitational Casting Competition will host casting teams from colleges and universities around the Midwest. Taking place during the AFS Wisconsin Regional Expo and Conference, the event invites student teams to present cast products they've created using school casting facilities. All projects in competition were completed by members of AFS student chapters.

Tags: Metalcasting, Students, Student Metalcasting Competition

Introduction to Greensand Casting

Greensand casting is a time-tested and highly versatile metalcasting process. Different foundries use different methods and materials, but greensand casting always involves creating molds by compacting moist, organically bonded sand around patterns. Whereas shell molding uses heat-bonded sand and no-bake casting uses chemically bonded sand to form molds, greensand casting is unique in that sand is bonded through naturally occurring compounds–in most cases, the bonding agent is clay.

Eagle Aluminum Cast Products makes use of greensand casting to produce large aluminum castings. The greensand process is very customizable and capable of manufacturing nearly any type of cast product. Here, we'll explore the processes, casting characteristics, benefits and challenges of the greensand casting process.

Tags: Metalcasting, Processes, Eagle Aluminum, Greensand Casting

Manufacturing Day 2018 at Eagle Alloy: Event Recap

Eagle Alloy was lively and bustling on Thursday, October 4th. That's no surprise: our Muskegon, MI campus is regularly buzzing through three shifts a day, five days a week. But this particular day brought in a larger crowd than usual: in celebration of Manufacturing Day 2018 we opened our campus to local schools and community representatives for a demonstration of modern metalcasting.

The goal of Manufacturing Day is to inspire the next generation of manufacturers, and we wanted to support that goal any way we could. By inviting students to witness our work firsthand, we aimed to provide an introduction to modern metalcasting and manufacturing. After nearly 40 years in business, we understand the importance of letting young people know about the exciting potential of metalcasting careers.

Tags: Metalcasting, Education, Community, Manufacturing Day, Event

Getting Started with the Eagle Group: What You Need to Know

The Eagle Group is comprised of three companies: a shell molding foundry, an investment casting foundry and a CNC machine house. Together, we're able to manufacture a broad range of metal products from concept to completion.

If you're looking for a new supplier for your raw or machined cast products, the Eagle Group could be the perfect fit. We pride ourselves on customer satisfaction, continuous improvement and outstanding work during all phases of the production process.

Tags: Metalcasting, Manufacturing, Product Design, Development, Capabilities, Product Development

Getting Started with Permanent Mold Casting

Permanent mold casting is a type of metalcasting involving reusable molds. Whereas other casting methods, like sand casting and investment casting, use disposable molds, permanent molds last much longer and can be used to produce hundreds, or even thousands, of identical parts.

Every project can be matched with the ideal casting method. For non-ferrous castings with medium-to-high volumes, permanent mold casting offers a long list of advantages.

Tags: Metalcasting, Aluminum Casting, Eagle Aluminum, Permanent Mold Casting