New Ebook: Heat Treatment Processes for Metalcasting and CNC Machining

The latest resource from the Eagle Group provides a comprehensive introduction to heat treatment in metalcasting and CNC machining.

This 40-page guide is available as a free download and is designed for manufacturing professionals, purchasers and engineers looking to deepen their understanding of heat treatment. It explores the role of heat treatment in enhancing the quality of cast and machined steel parts, ultimately helping purchasers procure the highest possible quality steel parts.

Tags: Heat Treatment

Heat Treatment: Tempering

The word ‘tempering’ generally means acting as a counterbalancing force, moving an object (or a situation) away from the extremes, toward a more balanced state. The same principle applies to heat treatment: when we temper a metal part, we are adjusting the proportion of one mechanical property against another. Specifically, we are increasing ductility while simultaneously decreasing strength and hardness.

Tempering is most often performed after a metal piece has been seriously stressed through hardening or after normalizing. When a material is hardened (especially quench hardened, the most common method of hardening), it is in an unbalanced state. In metallurgical terms, we say the metal is unstable: its molecules would like to rearrange into a more stable structure, but the quench hardening process freezes them before they get the chance. Likewise, the process of normalizing takes the steel molecules through a phase transformation, leaving stresses in its wake. (For a longer discussion of phase transformations, check out our Introduction to Heat Treatment for Cast Parts.)

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Annealing

The heat treatment known as annealing encompasses a group of processing heat treatments. Unlike thermal processes that are used to improve the strength and wear resistance of a part (such as hardening heat treatments), processing heat treatments are used to prepare a workpiece for further manufacturing processes. Chiefly, this means improving a material’s responsiveness to machining or cold-working by restoring (and even enhancing) ductility.

After an annealing process, the part can be expected to go to the machine shop for additional subtractive manufacturing, or to a mill to be cold worked. In fact, annealing makes machining and cold working easier (even possible) by relieving internal stresses, reducing hardness, increasing ductility and toughness, and softening the material to make it more machinable and workable.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Quenching

Imagine a medieval blacksmith hammering a sword fresh out of the fire. With the weapon still red-hot, he dunks it in water. The water hisses and boils around the submerged steel as it turns color from glowing orange to grey. This iconic scene of rapidly cooling a workpiece is called quenching, or quench hardening, and is one of the oldest and most common heat treatment processes used to harden and strengthen common carbon steels. In modern metallurgy, superior corrosion resistance for most stainless steels is also an important property achieved through quenching.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Stress Relief

Internal stresses form naturally during many manufacturing processes. Machining, stamping and welding, for example, are common manufacturing methods that augment the amount of stress in a material’s fabric. And although stress build-up is a natural byproduct of these processes, too much of it leads very commonly to part distortion. Most of these stresses must therefore be removed before a part can be considered ready and safe to use. Thanks to heat treatment, these stresses can be relieved (without changing a part’s mechanical properties) through a thermal process known as stress relieving.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Hardening

Hardening a metal achieves much more than simply making it mechanically harder. It also improves strength, making the alloy more resistant to plastic deformation, and can aid with corrosion resistance. However, a harder metal is also often a more brittle metal. As such, hardening is usually just one part of a properly designed heat treatment plan.

Because hardening can be accomplished through numerous heat treatment strategies, it’s important to know what options are available to a casting customer, how the methods differ, and where hardening fits into the master plan.

In this article, we’ll explore the science and practice of hardening, and explain when conditions are appropriate for a particular hardening strategy. Whether you’re working with the Eagle Group or another metal manufacturer, hardening is an important step in manufacturing, so it’s good to know the basics.

Tags: Processes, Metallurgy, Heat Treatment

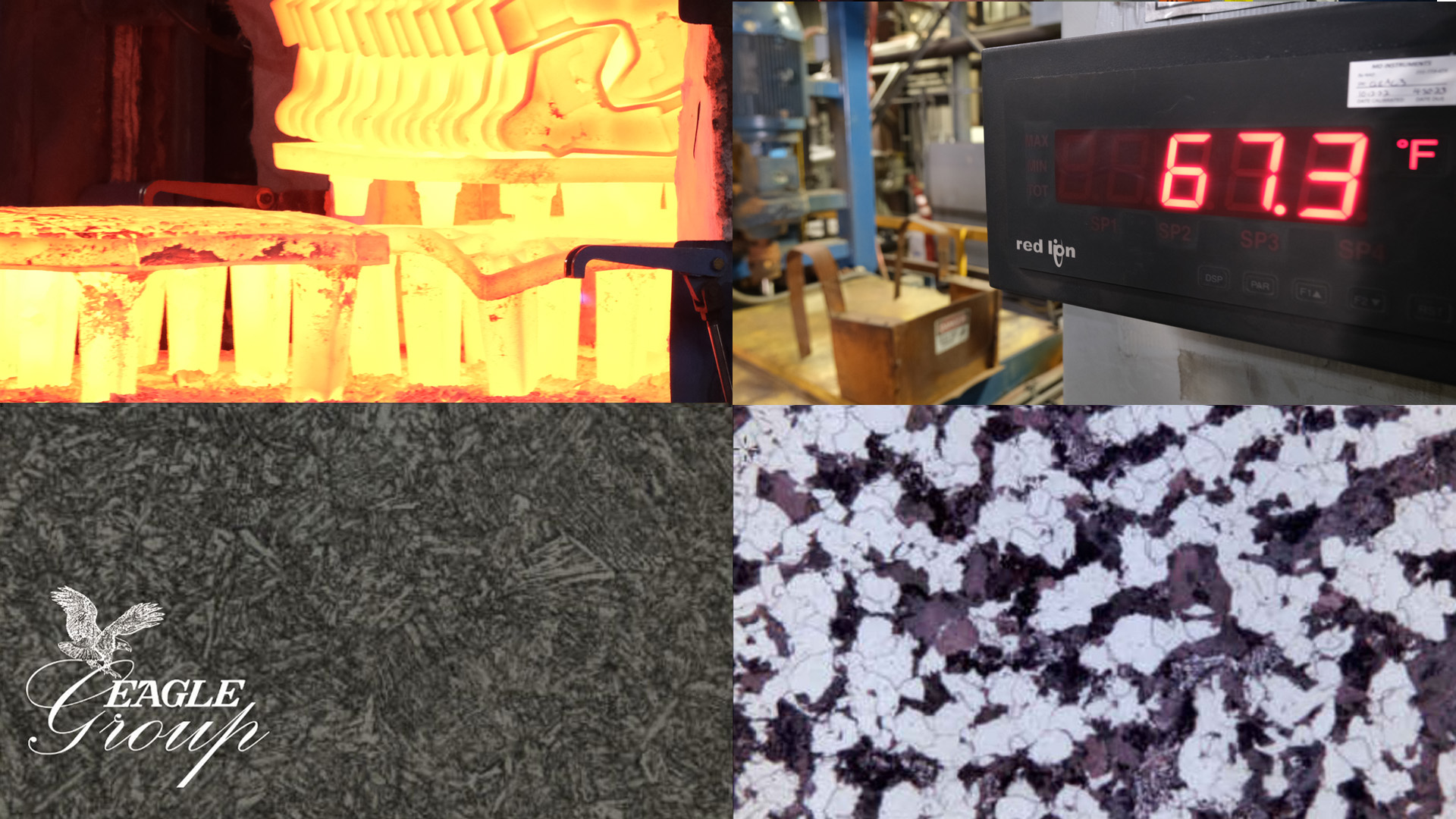

Heat Treatment: Normalizing

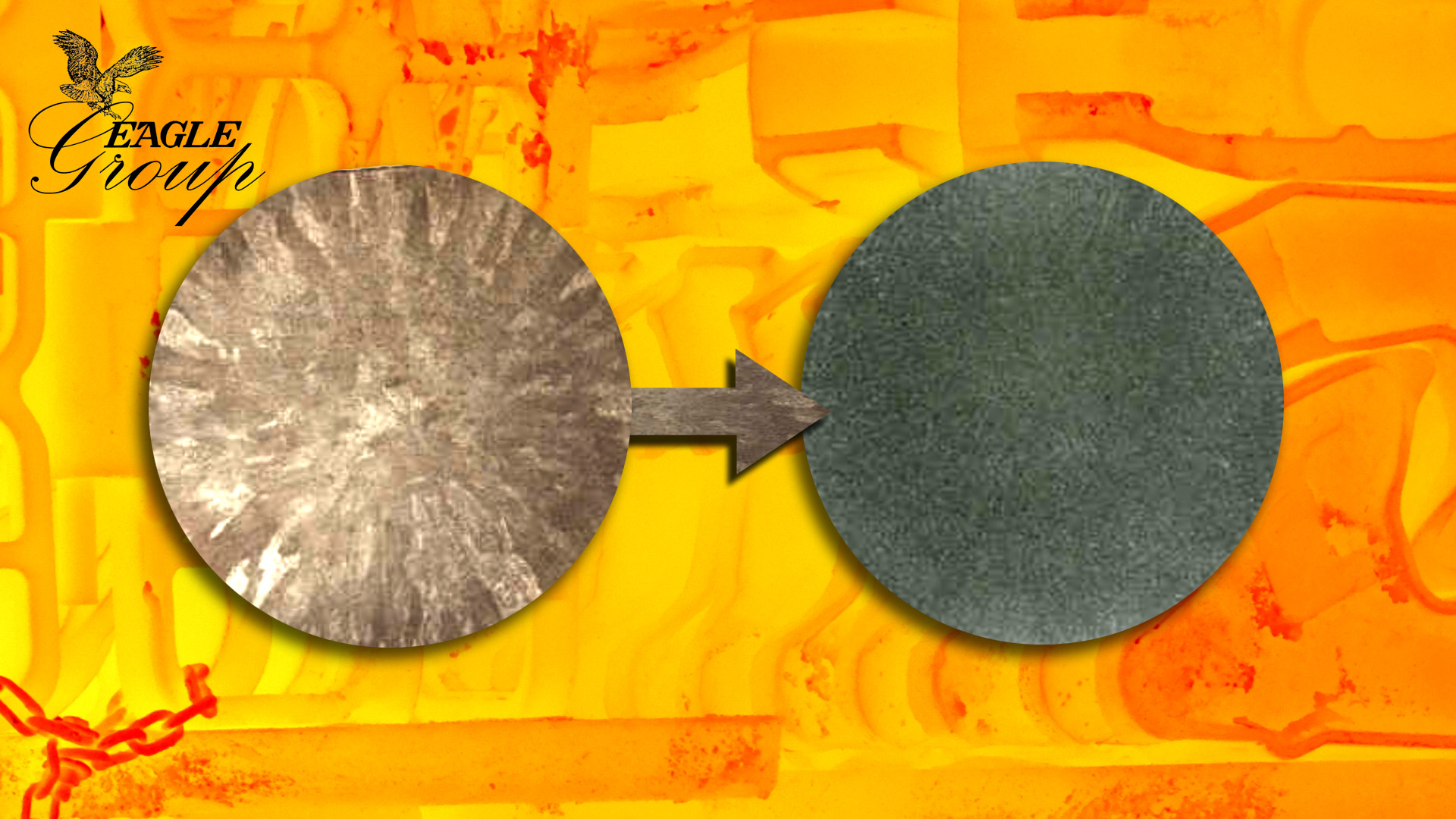

Normalizing is one of the most common heat treatments used in manufacturing carbon steel. It is a vital process to ensure that the mechanical and physical properties of a carbon steel workpiece are integrated and distributed uniformly across the material.

In steelmaking, material uniformity is achieved by carefully controlling a casting’s microstructure – specifically, its grains. Grains are distinct areas of crystal structures oriented in the same direction. Multiple grains together make up a metal’s structure. The goal of normalizing is to target these grains in order to even out the differences between them, resulting in a more mechanically stable product. It’s for this reason that the process is named as such: it ‘normalizes’, or homogenizes, grain size, shape, and orientation.

Tags: Processes, Metallurgy, Heat Treatment, Normalizing

Heat Treatment in CNC Machining

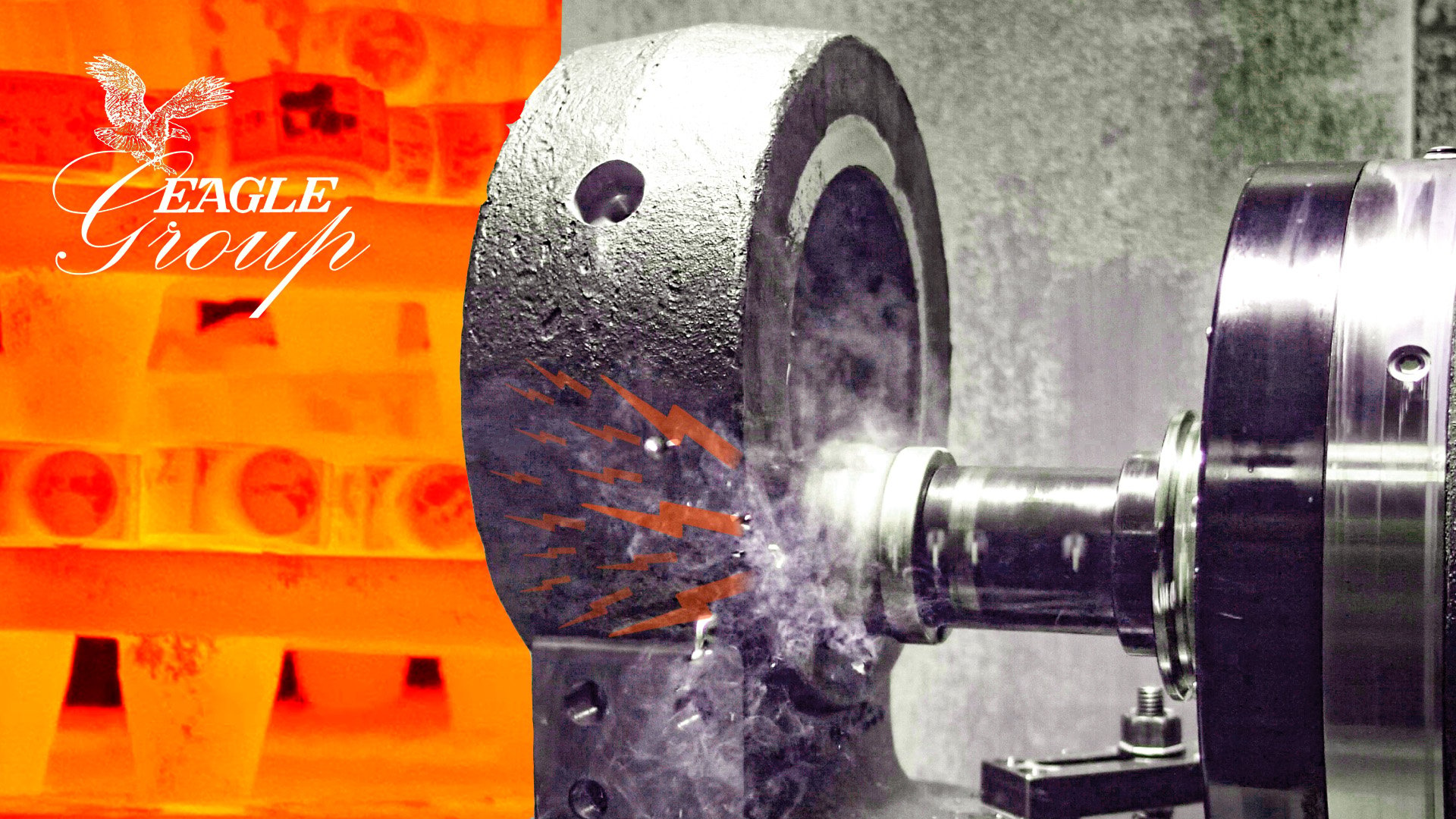

In this article, we’ll discuss how experienced machine shops like Eagle CNC think about the complex relationship between heat treatment and machinability. Determining where heat treatment fits into the CNC machining process is a vital consideration for machining parts to net shape quickly and cost-effectively.

Eagle CNC is the Eagle Group’s state-of-the-art machine shop, specializing in CNC machining of both ferrous and nonferrous castings, forgings, bar stock and burn outs. At Eagle CNC, we machine new parts directly from raw stock, or from parts that have been shell cast or investment cast by our sister companies, Eagle Alloy and Eagle Precision. While our workpieces start in a variety of states, nearly every product we machine undergoes heat treatment before delivery.

Tags: CNC Machining, Eagle CNC, Metallurgy, Heat Treatment

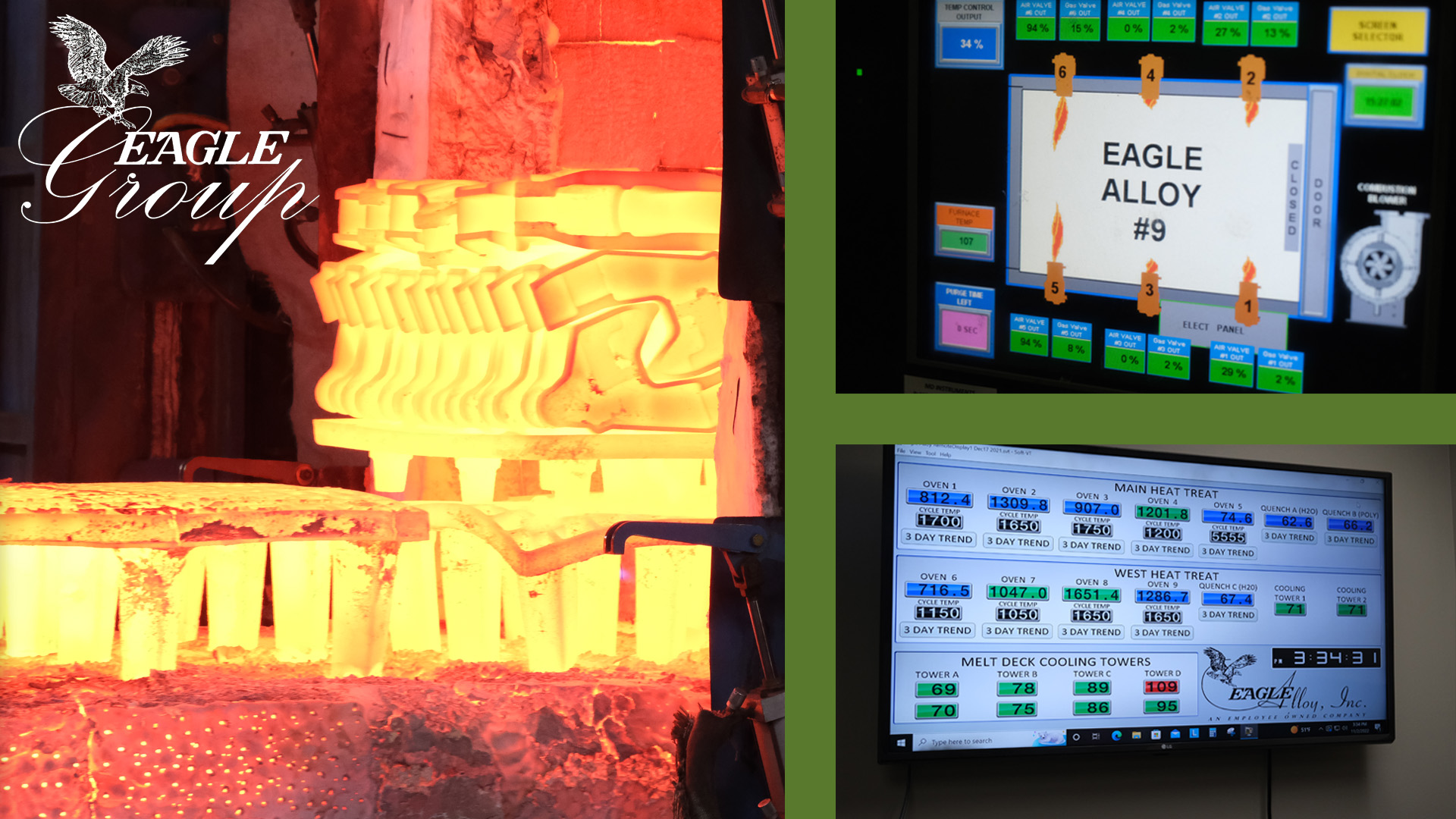

Heat Treatment for Cast Products at Eagle Alloy

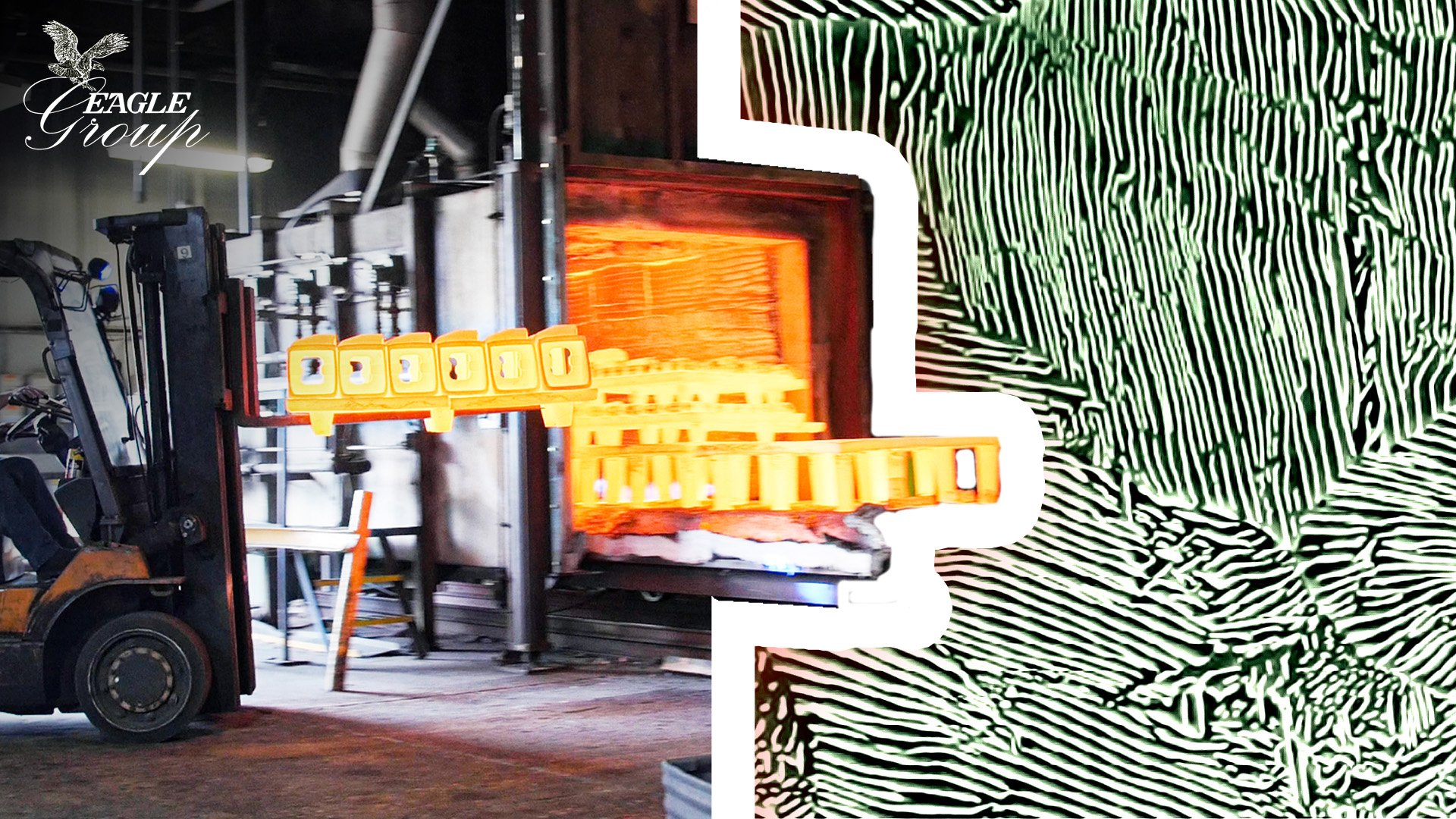

Eagle Alloy provides a wide range of metalcasting services. In addition to casting hundreds of alloy grades that can be formed into virtually any castable shape, our foundry is fully equipped to heat treat the majority of parts we manufacture. In this blog, we’ll be opening the doors to our heat treatment facilities. You’ll get to know what kind of heat treat equipment we utilize to deliver superior products that consistently meet performance expectations.

Casting a part into its required shape does not fully prepare it for a life of service – only heat treatment can ensure a part performs exactly how it should. With the exception of a handful of nickel-based specialty alloys, Eagle Alloy heat treats just about every part that is cast in our facilities. From annealing and normalizing to stress relieving and quenching, we have the furnaces, quench tanks, data and expertise to take a product from inception to delivery.

Tags: Eagle Alloy, Metallurgy, Heat Treatment

Introduction to Heat Treatment for Cast Parts

Metal manufacturers utilize a number of tools to control the mechanical and physical properties of raw materials. An alloy’s chemistry is only one part of the equation: obtaining the final properties can only be achieved through heat treatment. In this introduction, we'll cover the following topics:

- Why heat treatment is important for metalcasting

- Heat treatment for carbon steel vs heat treatment for stainless steel

- The importance of using ASTM standards

- Key heat treatment processes used by foundries and machine shops

Heat treatment is a broad term describing a range of thermal processes used to control an alloy’s properties. These processes ensure a finished product carries the mechanical and physical properties demanded by its application. Encompassing both heating and cooling, heat treatment incorporates a few distinct and equally important phases:

- Ramp-up: heating the metal;

- Soak: maintaining the metal at a desired temperature for a specified amount of time;

- Cooling: cooling to a specified temperature at a controlled rate and in a controlled environment.

Tags: Metallurgy, Heat Treatment