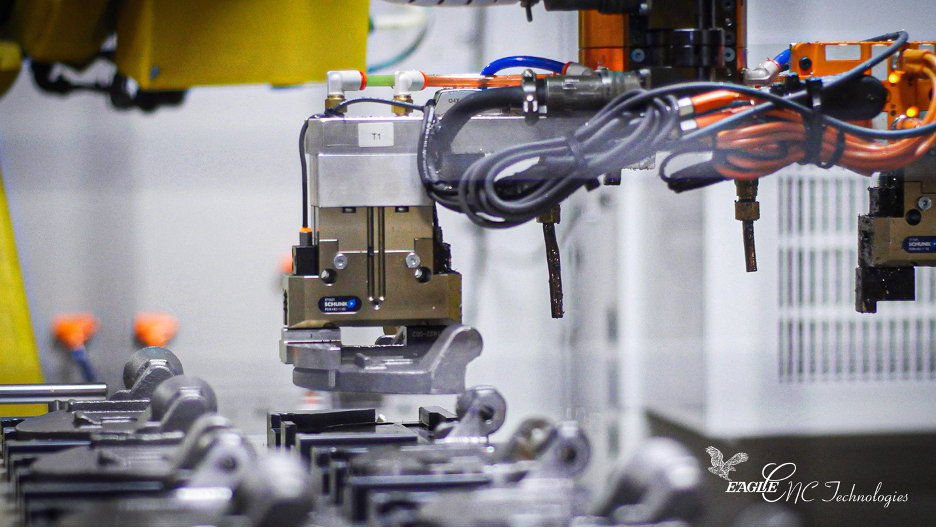

Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

New Resource for Manufacturers: CNC Machining Process Guide

The latest resource from the Eagle Group focuses on CNC machining and high-tech inspection. Our ebook CNC Machining Process Guide dives into the history, current practices and processes of CNC machining and advanced metrology. Perfect for anyone looking for a better understanding of precision machining in the 21st century, our new resource is available now as a free download.

Tags: Machining, CNC Machining, Metrology

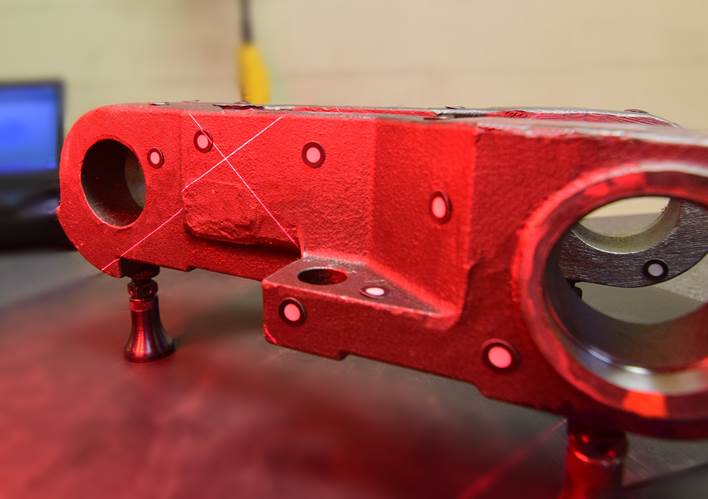

Designing Cast Products: High-Tech Inspection for High-Quality Parts

During the Eagle Group's product design process, sample runs of new cast products are subject to some of the most rigorous inspection processes available. The inspection methods we use prove to our customers that their parts will conform to specified tolerances and be free of defects. From magnetic particle inspection to laser scanning, we make sure that every new product passes a gamut of tests before it ships to the customer.

The Eagle Group regularly makes use of robust inspection technology to discover and diagnose any flaws or defects present in metal parts. In some cases, we use these methods to reverse engineer an existing part brought to us with defects. In other cases, we've pinpointed flaws in the initial design that lead to downstream manufacturing challenges.

Tags: Metrology, Inspection, Product Development

How Eagle Alloy's Handheld Laser Scanner Leads to Better Cast Products

Product development processes vary widely from foundry to foundry. The Eagle Group's Product Development blog series aims to highlight practices used by leading foundries that prioritize quality in every part they produce.

One product development practice that sets Eagle Alloy apart from other shell molding foundries is their use of a handheld laser scanner for inspection and dimensional reporting. This technology greatly improves the accuracy of dimensional reports, and makes it easier for customers to verify that new parts meet their requirements.

Tags: Metrology, Product Design, Development, Inspection, Product Development, Technology, 3D Scanning

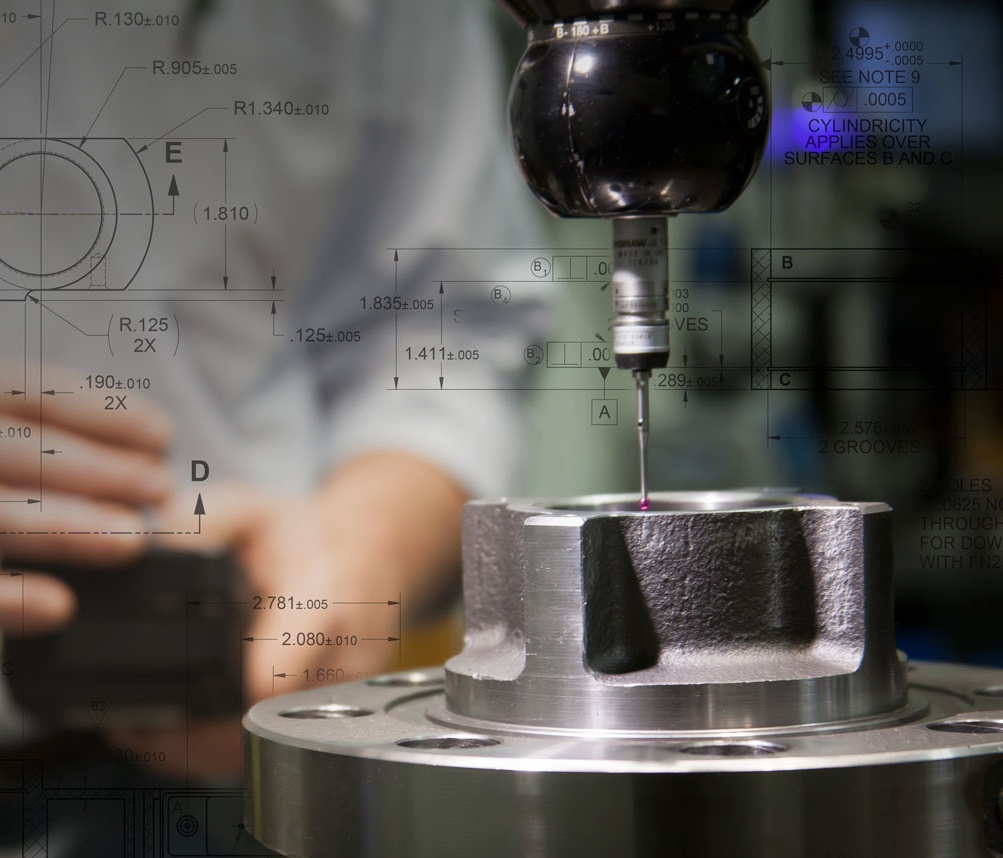

CNC Metrology: What Can a CMM Measure?

Coordinate Measuring Machines, known more often as CMMs, are a staple of industrial metrology. Of the thousands of variations of CMMs, you're likely to encounter at least one version in every manufacturing quality control department. You might not recognize it at first because CMMs can look like, well, pretty much anything–but in any form, these hard-working machines allow manufacturers to accurately measure a long list of product characteristics.

Sure, manufacturers could still measure their products the old fashioned way–with a good set of calipers and a lot of trigonometry–but in today's competitive environment, we need to take measurements in minutes, not days. We also require superior accuracy, sometimes down to .00005".

Tags: CNC Machining, Metrology

Measuring Standards: From Pharaohs' Forearms to the Speed of Light

Modern manufacturing wouldn't be possible without rigorous standards of measurement, along with sophisticated tools and techniques to help us measure tools, workpieces and finished products.

CNC machining is a prime example of the practical uses of modern measuring, or metrology. In metal-based manufacturing, CNC machining is often the last process before a part is delivered. Without incredibly accurate and precise ways to measure and cut, many of the metal products we take for granted would be impossible to produce.

The history of measurement is the story of how human civilization strove to find new ways to measure accurately, and it all leads up to modern metrology.

Tags: Machining, CNC Machining, Metrology, History

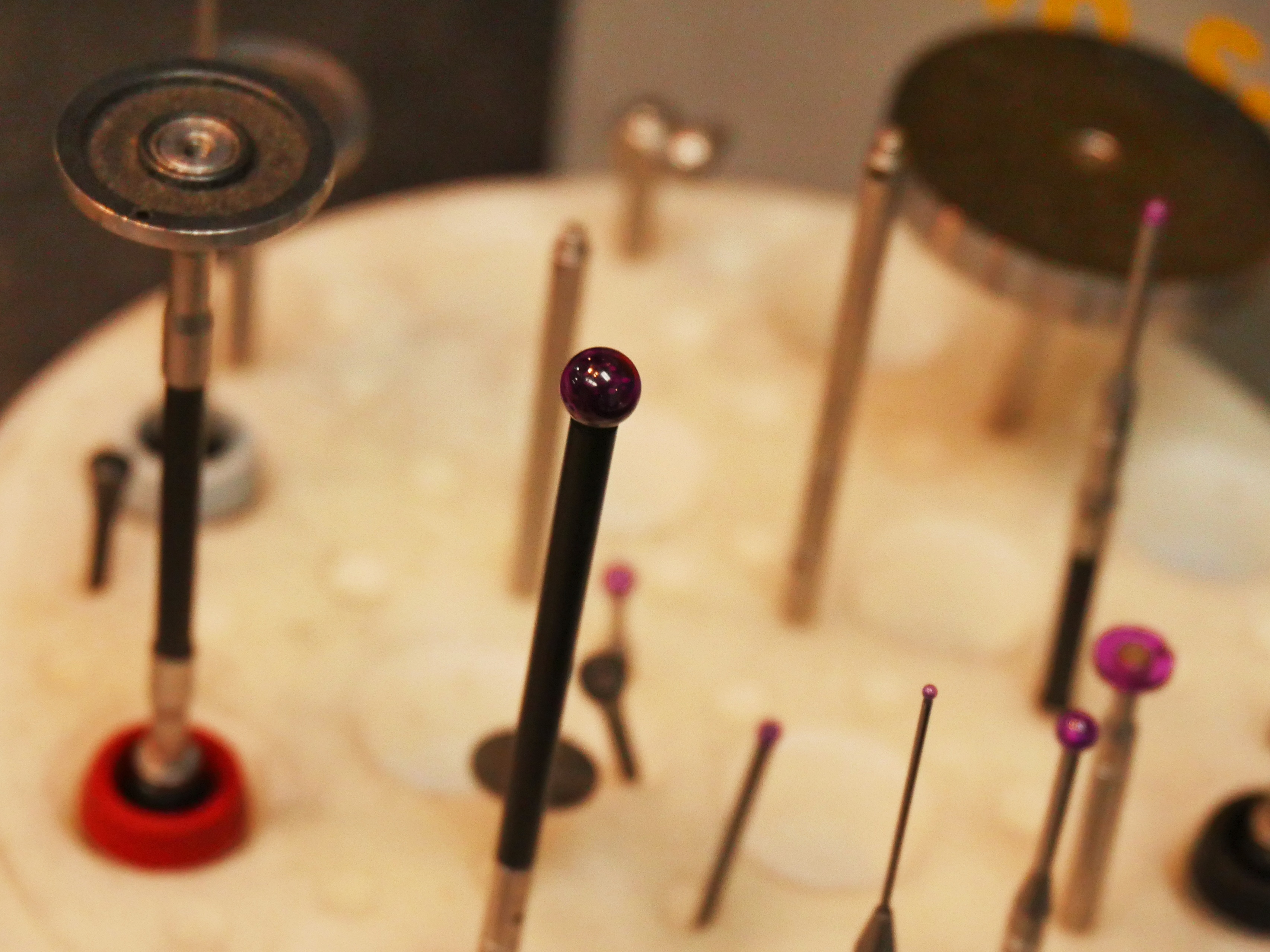

7 Essential Metrology Tools for Modern CNC Machine Shops

Metrology is the science of measurement. In CNC machining, principles of metrology need to be applied throughout the production process to ensure that each part is machined to the right size and shape, in accordance with specified tolerances.

It’s simple enough to take a ruler or a measuring tape and mark out inches or millimeters. But measuring dimensions of CNC machined parts – many with tolerances tighter than +/- .001 inch – is a whole other ball game. When you’re dealing with measurements that small, you need to have sophisticated measuring tools, and the knowledge to use them.

Tags: Machining, CNC Machining, Metrology