Finding the Perfect Balance: Case Study of Continuous Improvement in Cast Aluminum Fan Propeller Inspection

Eagle Aluminum specializes in permanent molding and greensand casting of aluminum products. In keeping with the Eagle Group's philosophy of continuous improvement, Eagle Aluminum's team is always looking for ways to improve our processes to achieve better quality, greater efficiency and reduced returns. This case study focuses on a recent innovation that dramatically improved the return rate for a line of parts without adding to processing time.

Introduction to Greensand Casting

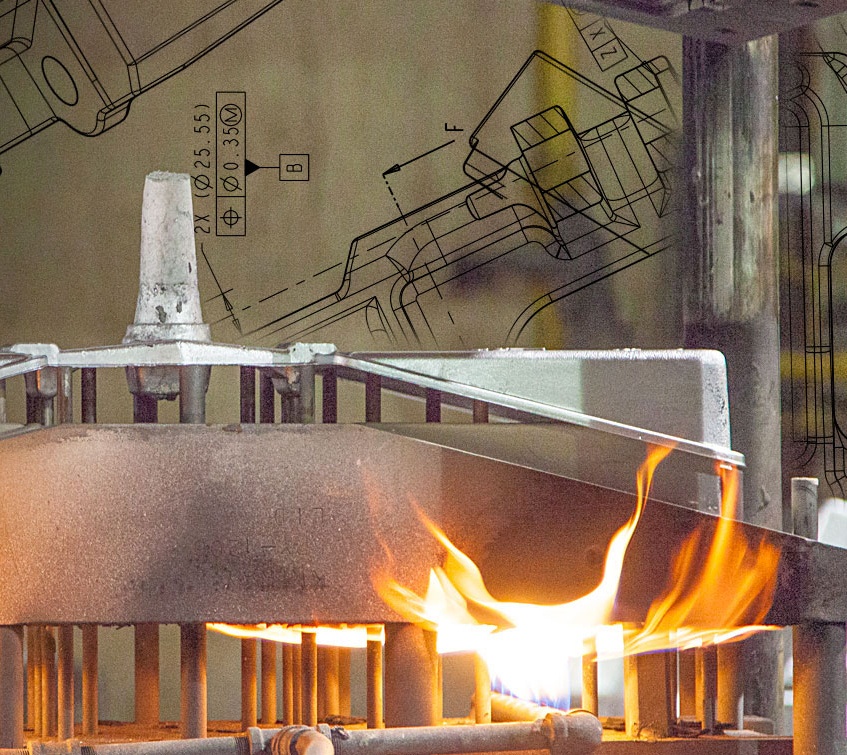

Greensand casting is a time-tested and highly versatile metalcasting process. Different foundries use different methods and materials, but greensand casting always involves creating molds by compacting moist, organically bonded sand around patterns. Whereas shell molding uses heat-bonded sand and no-bake casting uses chemically bonded sand to form molds, greensand casting is unique in that sand is bonded through naturally occurring compounds–in most cases, the bonding agent is clay.

Eagle Aluminum Cast Products makes use of greensand casting to produce large aluminum castings. The greensand process is very customizable and capable of manufacturing nearly any type of cast product. Here, we'll explore the processes, casting characteristics, benefits and challenges of the greensand casting process.

Tags: Metalcasting, Processes, Eagle Aluminum, Greensand Casting

Getting Started with Permanent Mold Casting

Permanent mold casting is a type of metalcasting involving reusable molds. Whereas other casting methods, like sand casting and investment casting, use disposable molds, permanent molds last much longer and can be used to produce hundreds, or even thousands, of identical parts.

Every project can be matched with the ideal casting method. For non-ferrous castings with medium-to-high volumes, permanent mold casting offers a long list of advantages.

Tags: Metalcasting, Aluminum Casting, Eagle Aluminum, Permanent Mold Casting

Casting Aluminum: Comparison of Methods

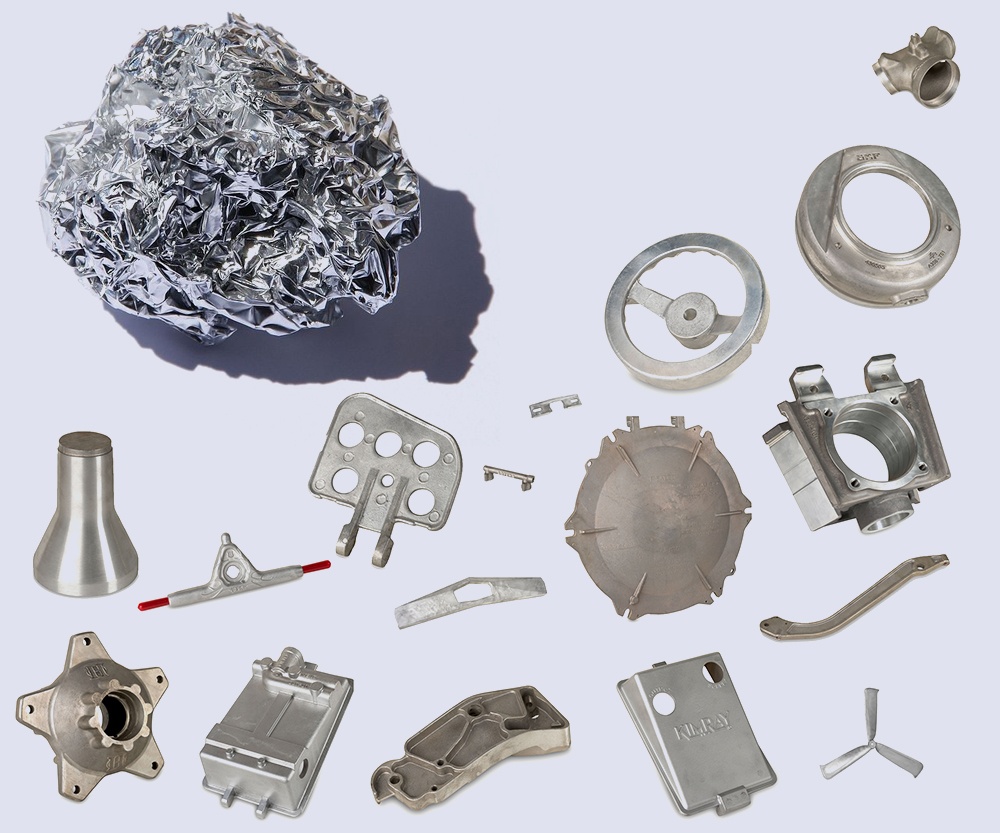

Aluminum can be shaped through a wide variety of process, including:

- Casting

- Extrusion

- Forging

- Rolling

For any type of metal, casting is arguably the most versatile of all of the forming processes, and results in the greatest variety of parts. In fact, the US Department of Energy estimates that over 90% of all manufactured goods contain metal cast products.

The same casting techniques used for other metals can be applied to aluminum, but some of the most popular methods used with aluminum are permanent mold casting, greensand casting and die casting.

Tags: Metalcasting, Processes, Aluminum Casting, Aluminum, Eagle Aluminum

New Eagle Group Resource Introduces Aluminum to Manufacturers

Eagle Aluminum Cast Products, Inc. recently published an ebook offering insight into manufacturing with aluminum.

Manufacturing with Aluminum: History, Forming Techniques and Best Practices draws on decades of experience, taking a holistic approach to aluminum manufacturing. Weighing in at just under 25 illustrated pages, the ebook aims to fill a gap between online resources and textbooks. According to Jim Smith, Technical Manager at Eagle Aluminum, “We want to make sure anyone curious about aluminum can get all the basic information they need, without searching all over the Internet or going back to school.”

Tags: Manufacturing, Aluminum Casting, Aluminum, Eagle Aluminum, Press Release, News

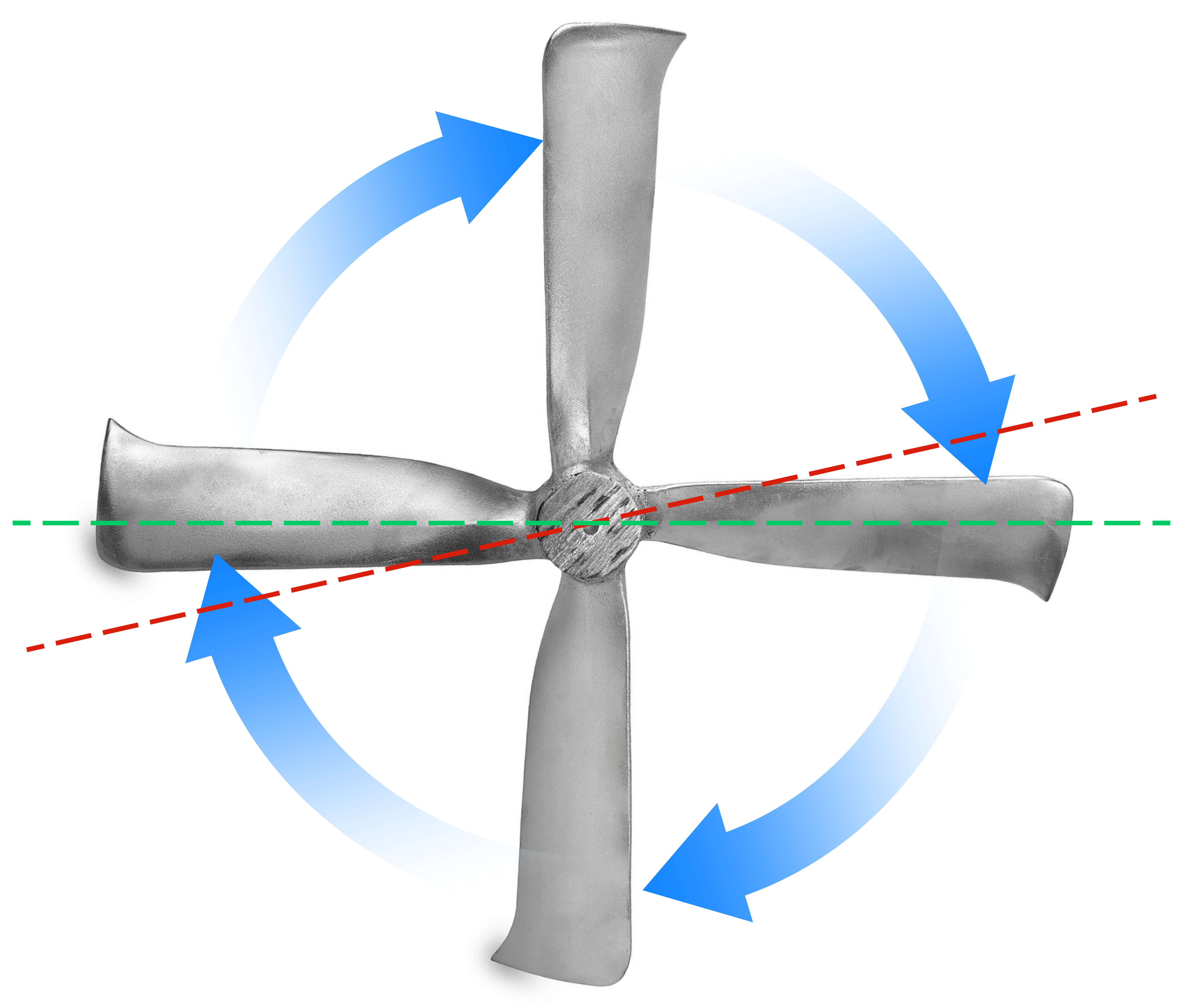

Aluminum Casting in Practice: A Case Study of Cast Aluminum Fan Blades

A major manufacturer of ventilation systems contacted Eagle Aluminum Cast Products, Inc. when demand was growing and they were ready to make a change.

The customer had already been producing 48” fan blades for agricultural use through green sand casting, but they’d outgrown that method. Demand projections suggested that permanent mold casting would yield lower per-part costs, with the added benefit of greater consistency.

Years later, EACP still produces fan blades for the customer through the process of permanent mold casting. Demand has increased even more, and product offerings have become more diverse. Read on to learn how EACP handles the design, production and delivery of this cast aluminum fan blade.

Tags: Aluminum Casting, Aluminum, All About Al, Case Study, Eagle Aluminum