Think Like an Owner: How ESOP Builds Innovation and Workforce Empowerment

ESOP is a way to transfer company ownership from one generation to the next—in many cases, this transfer happens when the original owners sell their stake in the company to their own employees. ESOP stands for Employee Stock Ownership Plan, but the acronym hardly conveys the potential of this empowering ownership model. That’s because ESOP is more than just a financial structure—it has the potential to shape company culture, fueling innovation, driving accountability and making an appreciable difference in the quality of customer relationships.

Our slogan at Eagle Precision is “Think Like an Owner,” which is a direct reference to our ESOP structure, and aims to boost awareness among our employees of the benefits we all share. Our employees are our company owners, and adopting that mentality has already led to a slew of innovations and improvements in our daily operations.

Tags: American Manufacturing, Eagle Group Values, Eagle Precision, ESOP, Employees, Human Resources

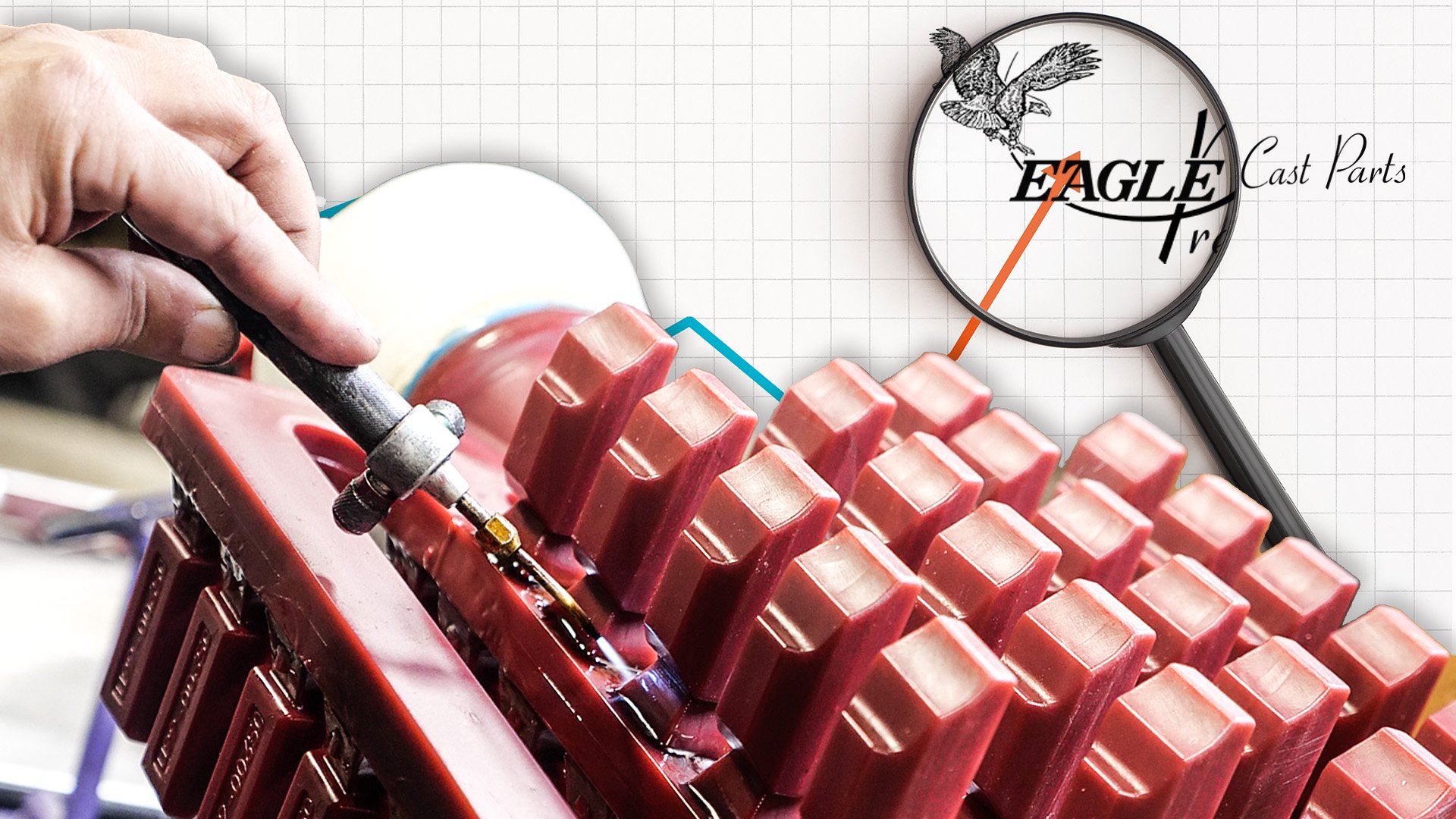

Continuous Improvement at Eagle Precision: Optimizing the Investment Casting Wax Room

This article is part of our series: Continuous Improvement at Eagle Precision

The wax room is at the heart (and start) of our investment castings. By injecting the wax room with fresh ideas, we’ve been able to greatly improve our pouring efficiency, leading to higher production yields, less downtime, reduced remelting rates, and faster delivery times.

Tags: Lean Manufacturing, Investment Casting, Eagle Precision, Continuous Improvement

New Article in Modern Casting Magazine: Modular Automation at Eagle Precision

Automation in investment casting is often seen as the domain of large-scale foundries, with a common perception that it requires major capital investment, significant floor space, and rigid shop-floor layouts. But what if there were a way to bring the benefits of robotic automation to foundries of any size?

Tags: Eagle Precision, Capabilities, Equipment

Continuous Improvement in Investment Casting

This article is part of our series: Continuous Improvement at Eagle Precision

Continuous improvement is an ongoing effort to make incremental changes in a company’s processes that improve efficiency and quality. While the concept is fairly simple, many businesses find it challenging to sustain continuous improvement over the long term.

Continuous improvement is one facet of Lean Manufacturing, which is a set of tools used to maximize output and minimize waste. The meaning of ‘minimizing waste’ in manufacturing is a far-reaching term. Some examples include:

- Unused material reclamation and recycling

- Cutting down on energy and transportation costs

- Reducing wait times

- Minimizing product defects and returns

Tags: Lean Manufacturing, Eagle Precision, Robotics, Continuous Improvement

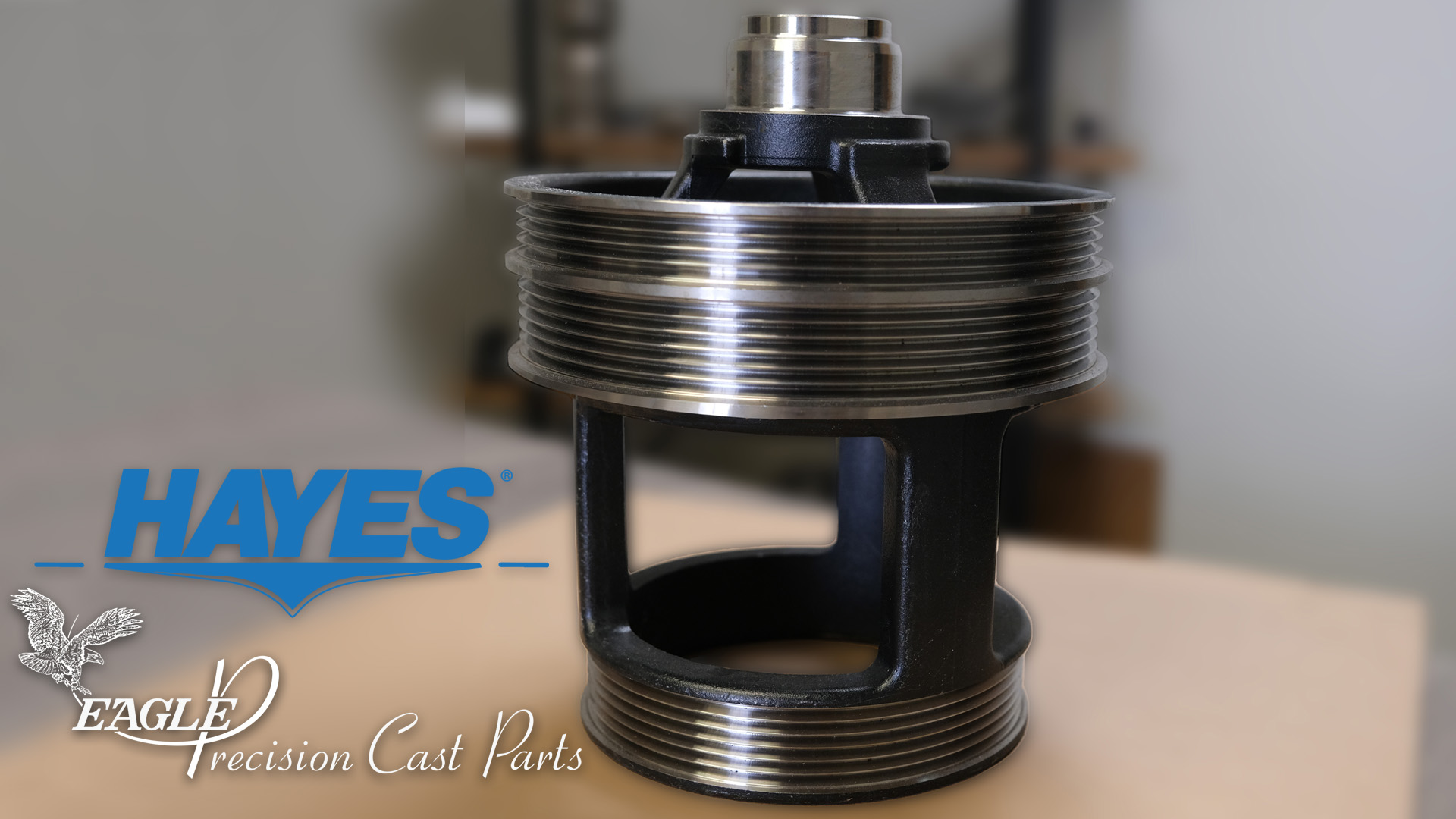

Case Study: Converting a Fully Machined Part to an Investment Casting

Manufacturers are aware of the benefits of machining: trained machine shops can produce complex parts with tight tolerances and all critical surfaces to spec. However, many manufacturers are learning that investment casting can produce cast parts to near-net shape, resulting in a host of benefits.

The machining process is often seen as the only way to manufacture a part with highly demanding specifications. Operating under this assumption, manufacturers sometimes choose to machine default without exploring other options. It’s also common for parts to be ‘over-toleranced,’ meaning they’ve been designed with tighter tolerances than the application actually calls for.

Robotics in Investment Casting

Our investment casting foundry, Eagle Precision, makes use of robotics in two steps of the casting process. We started with a robotic dipping cell and expanded into two, followed by a third robotic cell that specializes in after-cast grinding. While robotic cells like these do require a large up-front investment, we’re already seeing company-wide benefits resulting from our use of robotics in investment casting.

Robots are becoming more and more common throughout the manufacturing industry, and investment casting is no exception. According to John Scott, VP of Sales at Buntrock Industries, the investment casting industry is seeing increased demand for robotics for three reasons: “lack of workforce availability, desire for increased process control and productivity, and improved health and safety.”

Tags: Investment Casting, Eagle Precision, Robotics, grinding

The Benefits of Machined Part to Casting Conversion

Metalcasting is a highly versatile manufacturing process. In fact, many manufacturing professionals are not aware of just how versatile it is, and they continue to produce parts through other less efficient methods. While there is certainly a necessity for fabrication and machining in the metal manufacturing world, these processes can sometimes be replaced by casting.

Tags: Machining, Investment Casting, Productivity, Eagle Precision

Our Experience with ISO Re-Certification

In order to maintain efficient and successful operations in the manufacturing industry, quality control is extremely important. At Eagle Precision, we have developed a thorough quality policy that governs how we do business, from customer onboarding to product delivery. A big part of our dedication to quality is our adherence to ISO standards. Eagle Precision has been ISO certified since 2006, and we recently went through a re-certification process–and passed with flying colors.

Tags: ISO Certification, Eagle Precision

CAST IN STEEL: Student Teams Compete to Cast the Best Steel Viking Axe

This year the Steel Founders' Society of America (SFSA) introduced a national competition to engage students with steel casting and help foundries connect with the next generation of manufacturing professionals. Inspired by History Channel's Forged in Fire, the Cast in Steel competition brings teams of engineering students from around the country together to find out who can cast the best Viking axe. Testing, judging and awards took place prior to CastExpo in Atlanta, GA.

Tags: Investment Casting, Eagle Precision, Airset Casting, Event, Student Metalcasting Competition, CastExpo, Trade Associations

The Rise of Robotics in Metalcasting and Machining

The use of robotics in manufacturing, including metalcasting and machining, has grown steadily since the 1970s. Industrial automation increasingly relies on robotics as a way to improve efficiency and replace monotonous, repetitive human tasks.

Robots are used for a wide variety of tasks in manufacturing, from transportation to assembly. In metalcasting and machining, robots can be used to complete nearly any programmable task, from dipping and pouring to grinding and milling.

Tags: Eagle Alloy, Eagle Precision, Robotics