Metal Properties: Strength

Past civilizations had practical reasons for caring about metal properties. They asked questions like “Can I break my enemy’s sword before he breaks mine?” or “How thick does my armor need to be to provide enough protection?” These warriors had a vested interest in material strength.

Even as far back as Ancient Rome, steel was prized for its ductility and strength. Steel alloys are still in high demand today, and it's primarily the same properties – strength and ductility – that make steel alloys vital to modern manufacturing. Likewise, the importance of strength as a metal property has not changed: knowing when any metal will begin to stretch, deform, and break is essential to understanding how it can be used.

Materials scientists and engineers commonly use two metrics to predict how a metal withstands stress and resists breaking: yield strength (also known as upper yield point) and tensile strength (also known as ultimate tensile strength). In the English and American system of measurement, strength measurements are designated in pounds per square inch (psi). In the metric system, these same units of pressure are known as Pascals (Pa) or Megapascals (MPa).

How Do We Measure a Metal’s Strength?

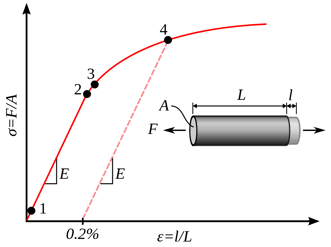

The chart at the right illustrates a tensile strength test. The y-axis (vertical) represents stress: the force applied to the material. Strain is represented on the x-axis, which describes the change in length (or deformation) due to the applied force. In the case of a tensile test, we are measuring the metal’s resistance to being pulled or stretched: imagine two clamps on both ends of a metal rod pulling in opposite directions. This graph shows how much the rod elongates as it is pulled harder and harder in both directions.

The chart at the right illustrates a tensile strength test. The y-axis (vertical) represents stress: the force applied to the material. Strain is represented on the x-axis, which describes the change in length (or deformation) due to the applied force. In the case of a tensile test, we are measuring the metal’s resistance to being pulled or stretched: imagine two clamps on both ends of a metal rod pulling in opposite directions. This graph shows how much the rod elongates as it is pulled harder and harder in both directions.

Note that at certain points there are changes in the relationship between the amount of stress and the resulting degree of strain:

- The first phase is proportionality, observable by the straight part of the solid red line ending at point 2. Here, there is a linear relationship between the amount of force applied (stress) and the amount the metal elongates (strain). During this phase, and anywhere up to point 3 at the elastic limit, changes to the shape of the metal are only temporary: when the force is removed, the metal rod will return to its original shape. This impermanent change in shape is called elastic deformation.

- The next phase of plastic deformation: when the line starts to curve after point 3, the material will not return to its original shape.

Elastic deformation is expected to some degree in all metal parts, but plastic deformation often leads to part failure. That's why understanding the point of plastic deformation, and the point at which the plastic deformation ultimately results in a complete part failure is so important to cast and machined parts.

Manufacturers are primarily concerned with the transition between elastic and plastic deformation. Understandably, our customers want to know how much force a material can withstand before it fails to return to its original shape.

How to Measure Yield Strength

Measuring yield strength has practical difficulties: the precise moment when a material graduates from elastic changes to permanent changes is almost impossible to observe. For that reason, material scientists developed a useful way to compare measurements called the offset yield strength. In the graph above, point 2 represents the true (but practically unobservable, so almost 'theoretical') yield strength, whereas point 4 is the widely accepted benchmark of a material's offset yield strength.

We measure offset yield strength by applying enough force to produce .2% of plastic deformation in the sample. This repeatable measurement standard makes it easy to compare materials and is listed as a standard reference in the ASTM standards: a key resource we use when recommending alloys to our customers.

How to Measure Tensile Strength

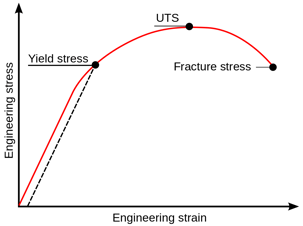

The graph at the right is another stress/strain curve illustrating both yield strength (also known as yield stress) and ultimate tensile strength. Remember that all deformations after the yield stress point are plastic, meaning the changes in shape are permanent. To crank things up a notch: after the ultimate tensile point (UTS) in the graph, the alloy bar begins to fracture. Simply put, tensile strength signifies the maximum amount of stress a material can withstand before breaking. In most cases this is far beyond what would represent actual part failure, but UTS is still a key metric that we use when choosing the right alloy for each product.

The graph at the right is another stress/strain curve illustrating both yield strength (also known as yield stress) and ultimate tensile strength. Remember that all deformations after the yield stress point are plastic, meaning the changes in shape are permanent. To crank things up a notch: after the ultimate tensile point (UTS) in the graph, the alloy bar begins to fracture. Simply put, tensile strength signifies the maximum amount of stress a material can withstand before breaking. In most cases this is far beyond what would represent actual part failure, but UTS is still a key metric that we use when choosing the right alloy for each product.

How Do We Measure Strength in Cast and Machined Metal Parts?

Measuring the strength of an actual product is not the same as measuring the strength of an alloy bar. In fact, part strength relies as much on theory as real-world testing. Planning for the strength of a part starts early in the design phase. We work with our customers through an extensive APQP process where we ask questions about part performance and operational environment to ensure that our customers’ designs will lead to functional, manufacturable products. This process also helps our customers—often with our guidance—select the ideal alloy for each part.

Our knowledge of material strength comes from resources like the ASTM standards, but it also comes from decades of hands-on experience producing cast and machined metal parts. We have produced thousands of parts, and each one is like a case study that helps us understand what works best in each unique situation. Along with standards, we apply that knowledge to every new project.

If our customers require further verification, we can perform a number of tests inside our casting facility. For example, we can carry out a hardness test on an actual cast part. While hardness and strength are not the same, there is a strong correlation between the two mechanical properties. We can also cast a bar in any alloy and perform destructive tests on it, much like those illustrated in the stress/strain curves above. This helps us determine whether an alloy we plan to use for a part conforms to customers’ performance requirements.

Why Yield Strength and Tensile Strength Are Important for Metal Manufacturers

In machine shops like Eagle CNC and foundries like Eagle Alloy and Eagle Precision Cast Parts, yield strength and tensile strength are crucial data points and figure heavily into the overall design of every product. Our customers often come to us with product designs and specific needs for metal properties. While we are not design-responsible, we do work with them to choose the best alloy that will achieve their desired properties while maximizing efficiency in the manufacturing process.

Eagle Group companies look at the manufacturing process holistically, so it’s more than just the material we cast that determines properties like strength. We closely control the material chemistry, handling, processing, and heat treatments that produce the material to meet the customer’s defined properties.

Once our cast parts are working in the field, their yield strength is put to the test. These parts often fit into more complex systems, and industrial products like valve bodies, tractor parts and rail ties undergo a broad range of stresses during everyday use. Components in any machine are expected to temporarily stretch or bend in fractional increments, as long as they don’t permanently deform or break during use. Making sure changes in shape are elastic and impermanent sums up the usefulness of understanding yield strength of each part.

On the other hand, ultimate tensile strength plays a major role in safety. If a component suffers an outsized impact load due to fire, earthquake, occupational accidents or other hazards, the plasticity of a metal is often responsible for absorbing the excess load, preventing a potentially dangerous situation. At the Eagle Group we manufacture a wide range of parts where failure is not an option, like Eagle Alloy’s modular construction parts or Eagle CNC’s train components. Whereas yield strength will make sure a part or appliance continues to work, tensile strength will make sure no one gets hurt.

Learn More About Metal Properties in our free 47-page ebook. Click below to download:

Tags: Metals, Metallurgy, Metal Properties, Mechanical Properties

Written by Jason Bergman

Jason Bergman is Senior Quality Engineer and Metallurgist at Eagle Alloy. He has been with the company since 2013.