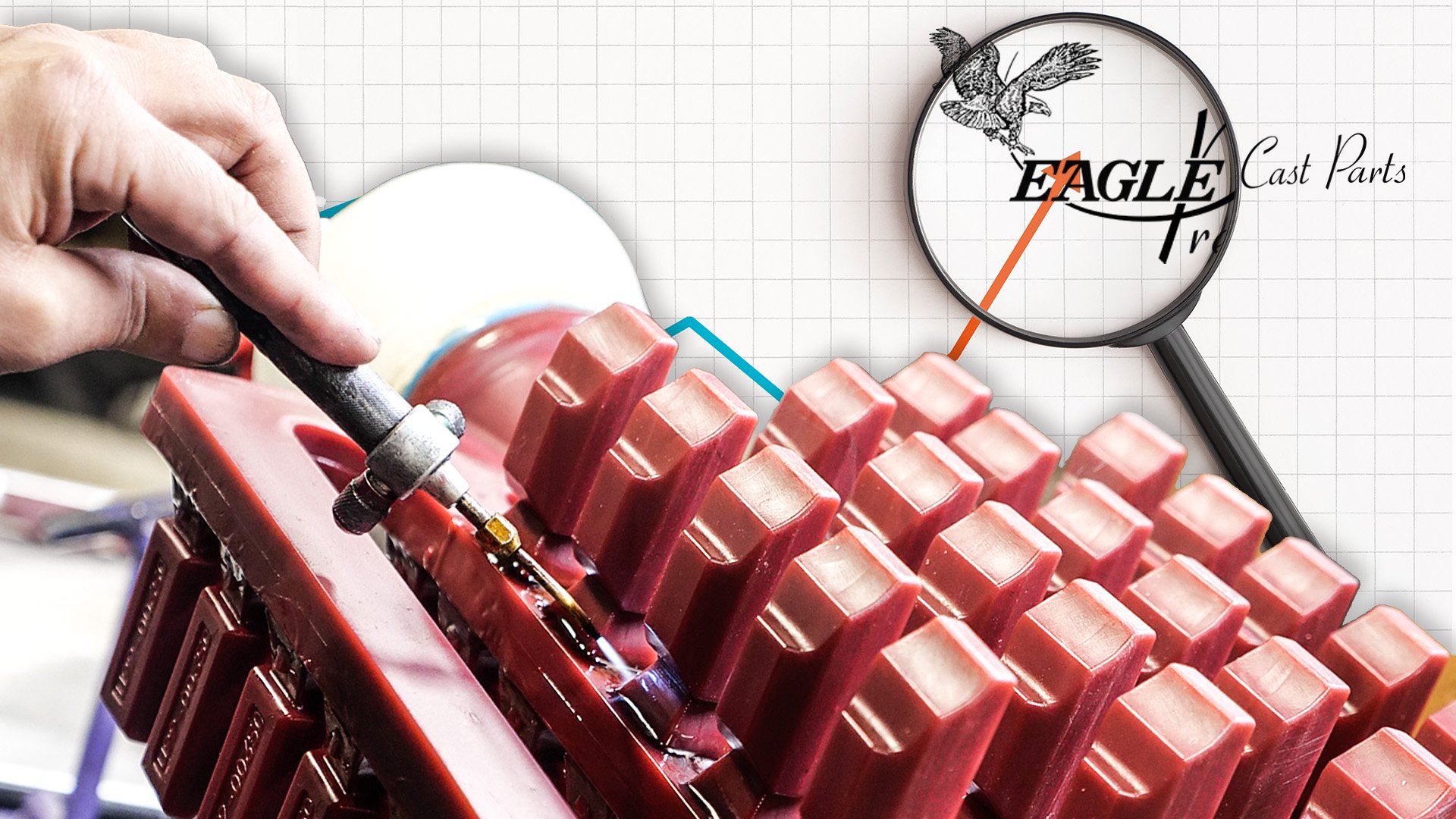

Continuous Improvement at Eagle Precision: Optimizing the Investment Casting Wax Room

This article is part of our series: Continuous Improvement at Eagle Precision

The wax room is at the heart (and start) of our investment castings. By injecting the wax room with fresh ideas, we’ve been able to greatly improve our pouring efficiency, leading to higher production yields, less downtime, reduced remelting rates, and faster delivery times.

Tags: Lean Manufacturing, Investment Casting, Eagle Precision, Continuous Improvement

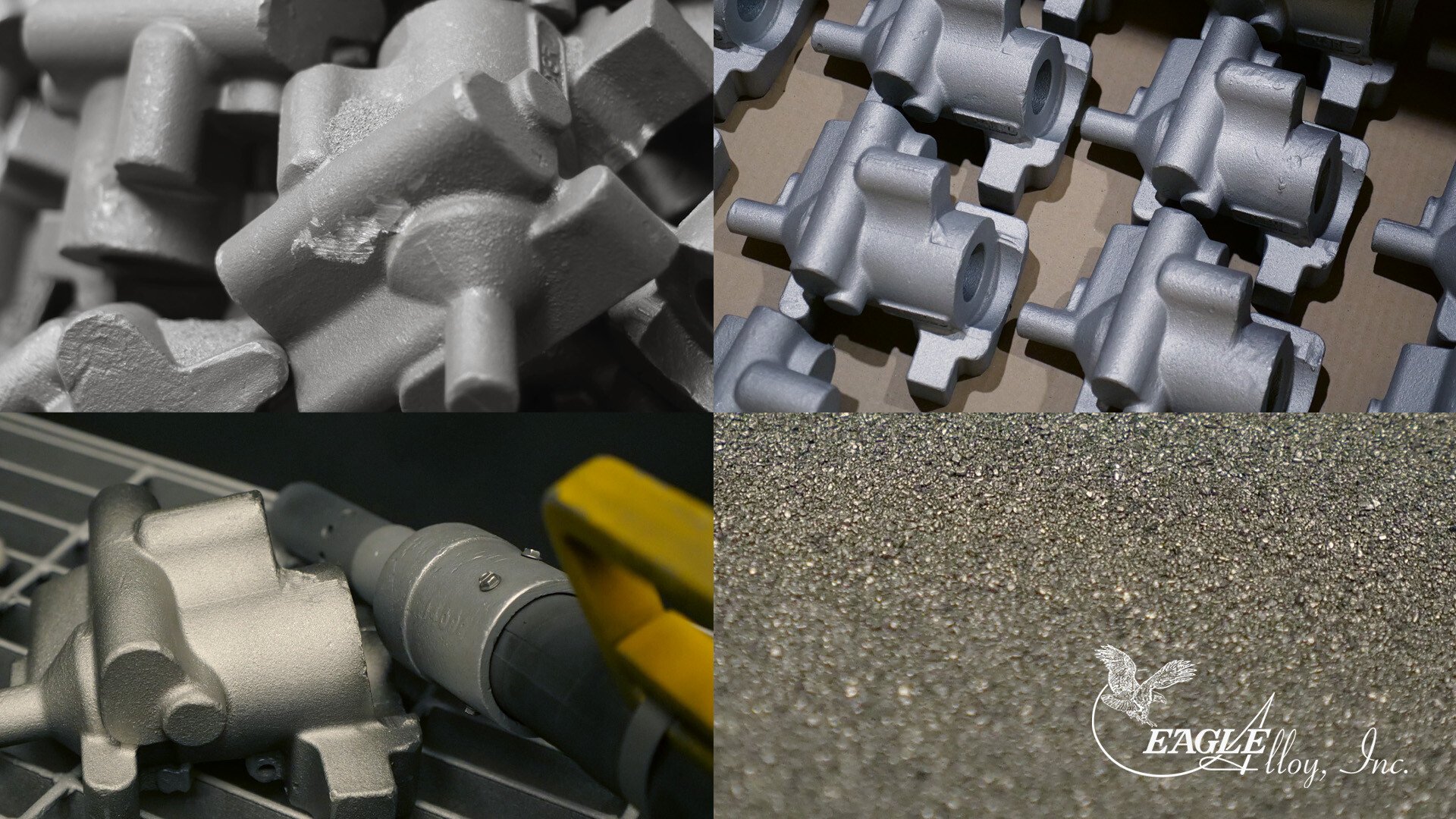

After Casting: Perfecting the Blasting Process

After a casting solidifies in the mold, the part undergoes a number of post processes to prepare it for delivery. One of the most commonly used post processes is blasting, an intensive cleaning process that removes debris and excess material from castings. At the Eagle Group, blasting plays a pivotal role in prepping casting surfaces for delivery or for further processing. Our latest investment in state-of-the-art stainless-steel grit and an optimized media blasting process is paying dividends for our customers and our employees by providing cleaner parts, less oxidation, and a safer workplace.

But getting to this point has been a years-long journey. Here's how we got here.

Tags: Lean Manufacturing, Eagle Alloy, Equipment, Continuous Improvement, Blasting

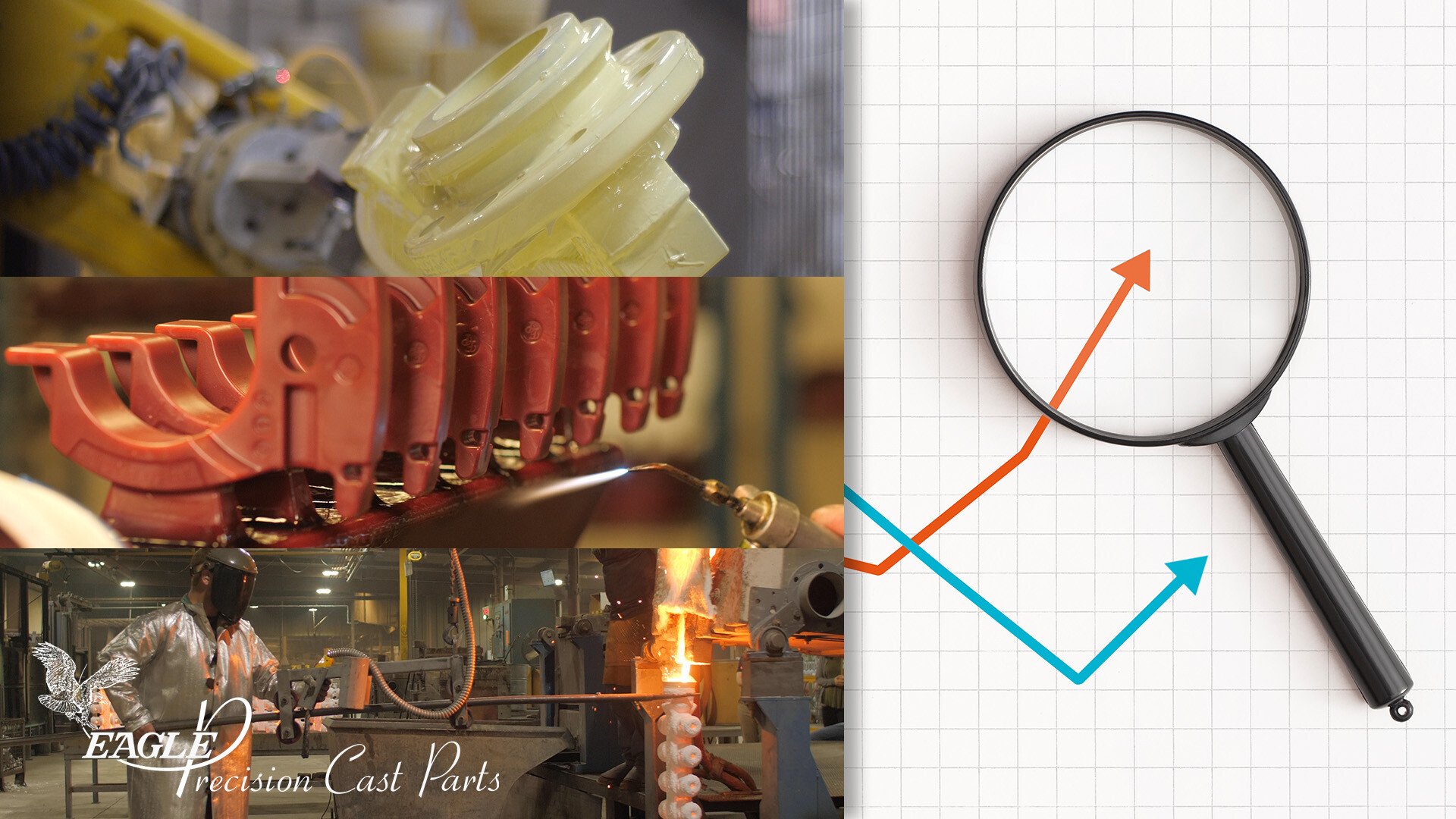

Continuous Improvement in Investment Casting

This article is part of our series: Continuous Improvement at Eagle Precision

Continuous improvement is an ongoing effort to make incremental changes in a company’s processes that improve efficiency and quality. While the concept is fairly simple, many businesses find it challenging to sustain continuous improvement over the long term.

Continuous improvement is one facet of Lean Manufacturing, which is a set of tools used to maximize output and minimize waste. The meaning of ‘minimizing waste’ in manufacturing is a far-reaching term. Some examples include:

- Unused material reclamation and recycling

- Cutting down on energy and transportation costs

- Reducing wait times

- Minimizing product defects and returns

Tags: Lean Manufacturing, Eagle Precision, Robotics, Continuous Improvement

Stories from the Lean Manufacturing Journey

Eagle Alloy has been practicing lean manufacturing for close to a decade. Beyond the benefits to productivity and efficiency imparted by lean tools, Eagle companies have come to see lean manufacturing as part of their company culture. The inclusiveness, creativity and quality improvement they’ve been able to foster has paid off dividends, both in workplace atmosphere and customer retention.

Lean implementation makes a more dependable supplier

Almost all the way back at the beginning of Eagle Alloy’s lean journey, about six months into their implementation of cellular manufacturing, the company was already seeing a noticeable productivity boost. They came into contact with a potential customer—we’ll call them Company A—who scheduled a shop tour at Eagle Alloy. Company A was already a successful manufacturer, but their casting supplier had recently gone bankrupt and they were looking for a replacement.

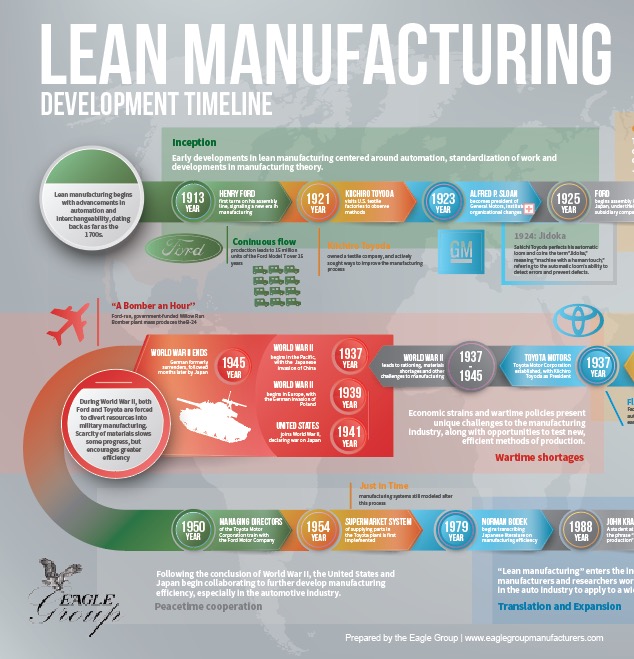

Infographic: Lean Manufacturing Timeline

The history of lean manufacturing dates back at least to the 1700s, when Eli Whitney developed interchangeable parts in order to deliver a massive order of muskets to the American Army.

It wasn't until 1988 that John Krafcik coined the phrase "lean manufacturing" in his research as an MIT student. For most of the 20th century, lean manufacturing was tied closely to industrial innovations in the United States and Japan. While it wasn't called "lean" for many decades, American and Japanese automakers laid the groundwork for the tools of lean manufacturing that we use today.

Case Study: Lean Manufacturing at Eagle Alloy

Eagle Alloy, Inc. was founded in 1979 and quickly grew from a short-run facility to a medium-to-high-production steel foundry. Despite the company’s success, its founders were not satisfied with the status quo. Having heard of developments in lean manufacturing, they decided to implement these tools in hopes of achieving greater efficiency, stability and quality throughout the production process.

5S: The Beginning

As with many production facilities beginning to experiment with lean manufacturing, Eagle Alloy started with 5S. 5S is easy to adapt to just about any environment, and the key to lean is customization. Every lean tool must be adapted to the particular type of production, to the size of the company and to the facility's space.

Tags: Lean Manufacturing, Eagle Alloy, Case Study

5 Lean Manufacturing Tools You Should Already Be Using

Lean Manufacturing principles encourage maximum efficiency for just about any production facility. Lean Manufacturing is also more of a necessity than ever, with cutthroat competition across the manufacturing industry forcing all players to up their efficiency levels.

If you're worried that your company isn't lean enough, take a look at these five tools from the Lean Manufacturing playbook.

Tags: Lean Manufacturing, Manufacturing, Efficiency, Productivity

What Is Lean Manufacturing?

Lean manufacturing helps manufacturers improve efficiency by eliminating waste in the production process, but what exactly is lean manufacturing? Is it a product, a procedure, a religion?

None of the above. Lean manufacturing is an adaptable set of “tools” that can be applied to any system of manufacturing–whether that system produces spring coils, jet engines or blog posts. It starts with identifying waste in a production process, and then focuses on eliminating that waste bit by bit until production is as streamlined and efficient as possible.

9 Ways to Improve Manufacturing Efficiency

This article was updated on July 10, 2025.

Efficiency is good for any business. It doesn’t matter if your company is manufacturing or service oriented. Greater process efficiency always offers a wide range of benefits over "business as usual."

On a broad level, manufacturing more efficiently can help cut costs, improve throughput and reduce environmental impact. All of these general benefits lead to additional benefits down the road, from increased sales and quality to improved company image.

Read on for 9 ideas to improve manufacturing efficiency.

Tags: Lean Manufacturing, Processes, Manufacturing, Efficiency

3 Ways Lean Manufacturing Lowers Casting Costs

Looking to lower the cost of your casting purchases? The key is to find a foundry that incorporates lean manufacturing principles into the process. These three principles can be applied to manufacturing castings, driving down costs significantly:

- Castability

- Bottleneck Solutions

- Optimizing Cycle Time

Tags: Lean Manufacturing, Metalcasting, Buyer's Guide, Purchasing Cast Products