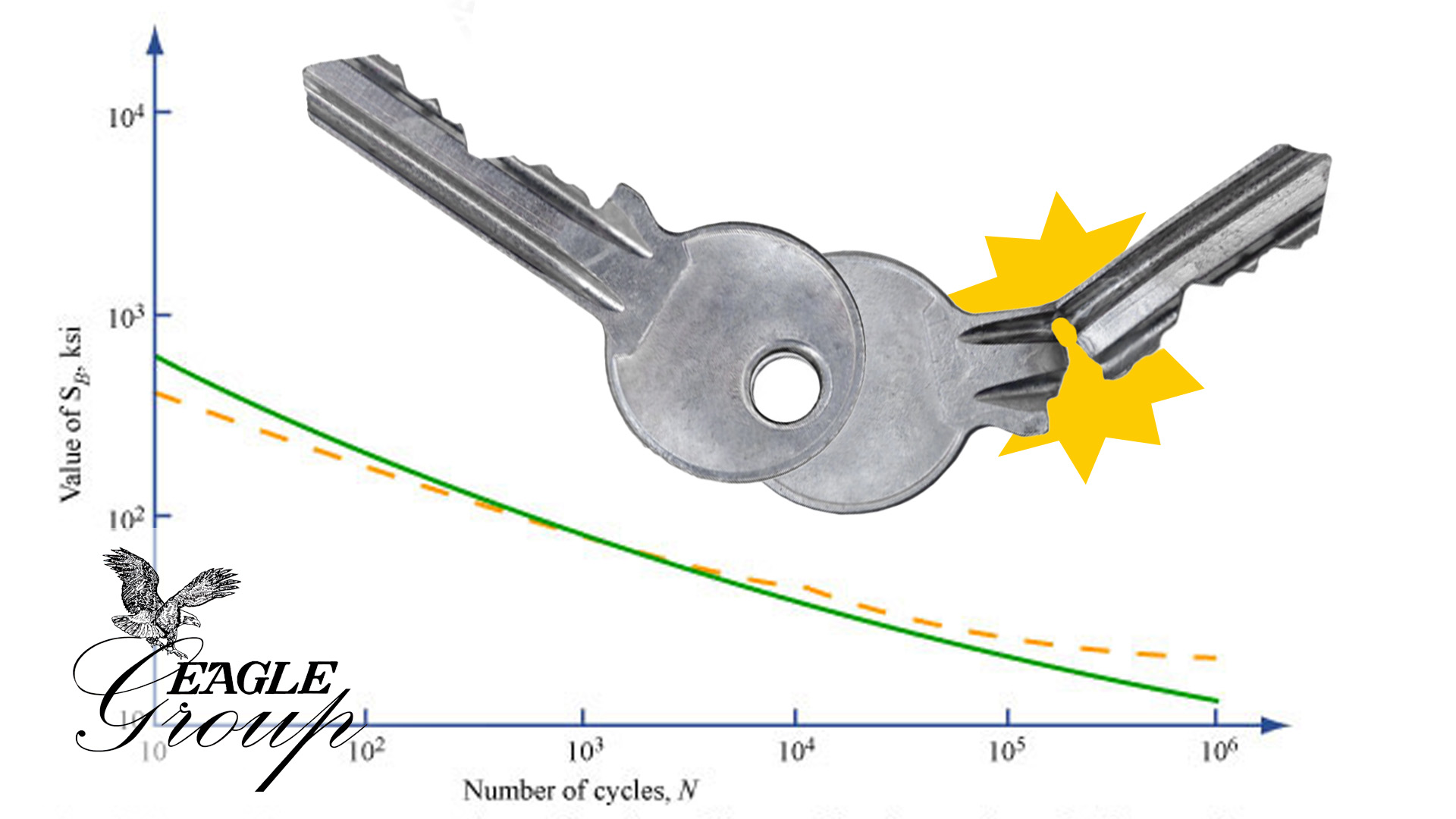

Metal Properties: Fatigue Resistance

Metal fatigue is the cracking and eventual failure of a metal workpiece under the stress of perpetual loading, a type of continual loading known in the industry as cyclic loading. Fatigue resistance in metal parts is the other side of the coin: it represents a part’s ability to avoid cracking and failure under cyclic loading. Not surprisingly, scientists and manufacturers alike have honed the processes necessary to produce components that resist failure from fatigue as efficiently as possible. Manufacturing parts with the aim of resisting failure from perpetual loading is vital for a part’s longevity in service, and for ensuring that our customers are receiving parts that meet a minimum of expected performance life.

Metal Properties: Toughness

Toughness is a mechanical property that measures the amount of energy a material can withstand, or absorb, before fracturing. In the context of other mechanical properties, toughness for steel products represents a balance of strength and ductility.

As a material term, toughness can sometimes cause confusion: two very different materials can both be considered tough. For example, an iron anvil is tough because its strength is very high, and it resists fracture by maintaining its material integrity thanks to its strength. On the other end of the spectrum, silly putty is also a tough material, not because it’s strong but because it’s very ductile and will resist fracture until you pull it far enough apart that the two ends separate. Anvils and silly putty are very different, but they’re similar in that they are both tough, and they both absorb a good deal of energy before fracturing.

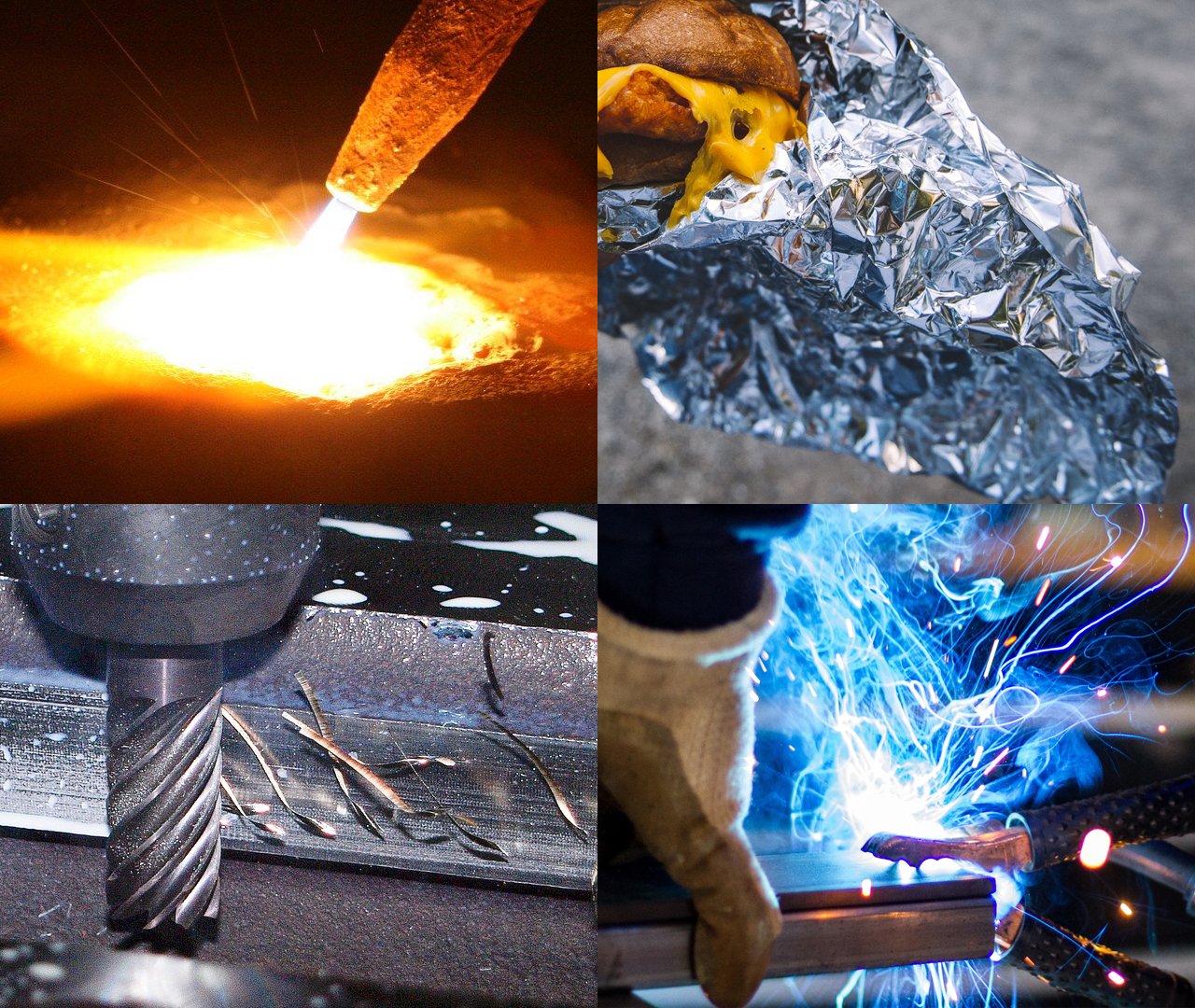

Metal Properties: Weldability

Joining multiple metal parts together into a single, cohesive unit is an indispensable process to manufacturing. Bolts, screws, and adhesives are often used to unite separate parts, but many applications call for a more solid connection. Thanks to the craft of welding, manufacturers are able to effectively create a single part from multiple components. Casting facilities are also able to use welding to repair minor casting defects, improving overall process efficiency and reducing part cost.

Understanding the weldability of various alloys is key to creating welds that last and parts that perform in the field. As a mechanical property, weldability is also an important consideration in designing and producing cast parts.

Tags: Welding, Metallurgy, Metal Properties, Mechanical Properties

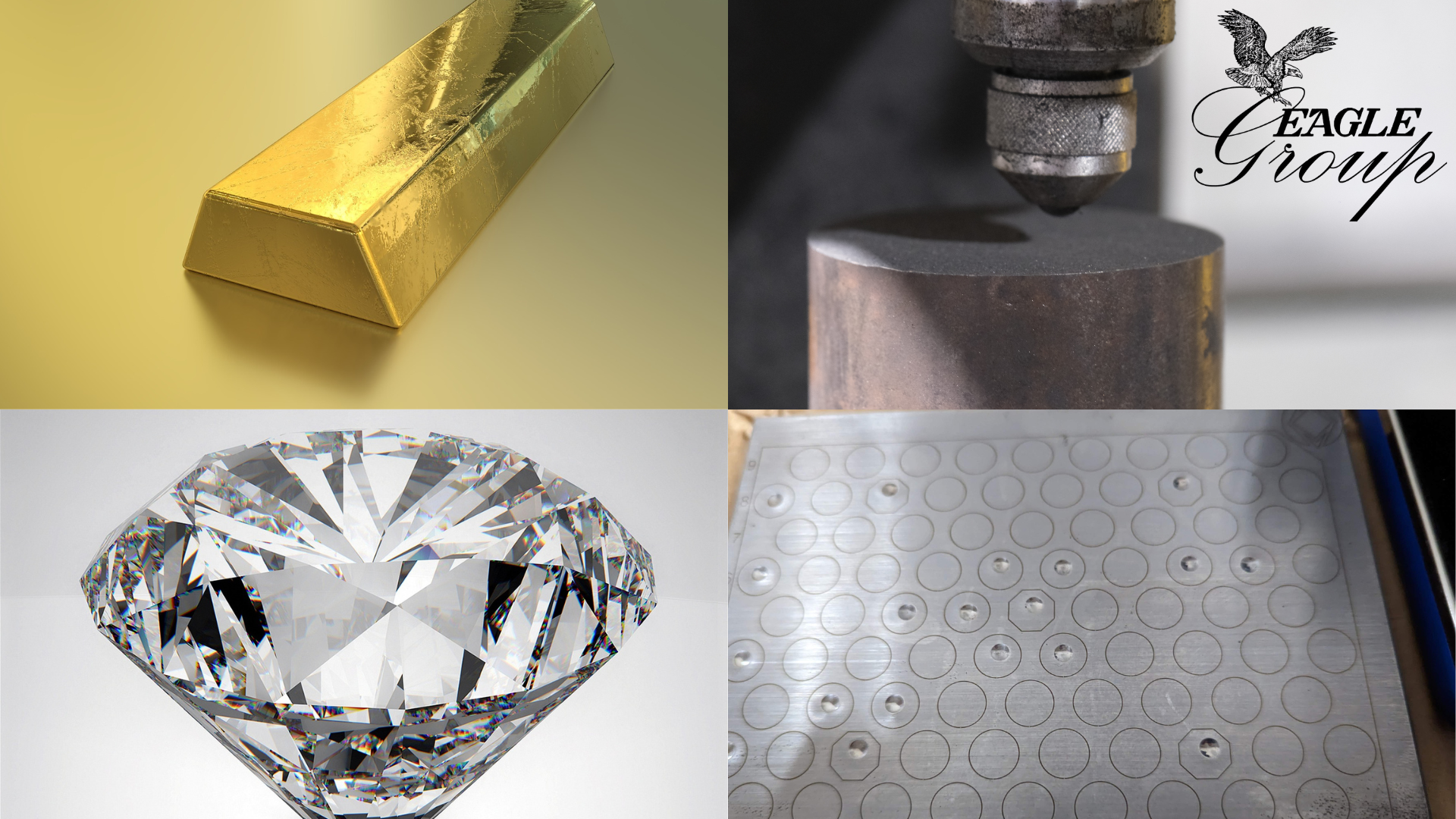

Metal Properties: Hardness

“Hardness” is a concept we use every day to compare objects: fresh bread vs. stale bread, a baseball vs. a softball. In manufacturing the definition is a bit more specific: hardness is a measure of a material’s ability to resist localized scratching or deformation by indentation at a specific loading location.

Our understanding of hardness and relative hardness between materials is key to manufacturing metal products. The correlation of hardness with other mechanical properties also makes it possible for us to predict, with a high degree of accuracy, the strength and ductility of a material without submitting it to destructive testing.

Tags: Metallurgy, Metal Properties, Measurement, Mechanical Properties

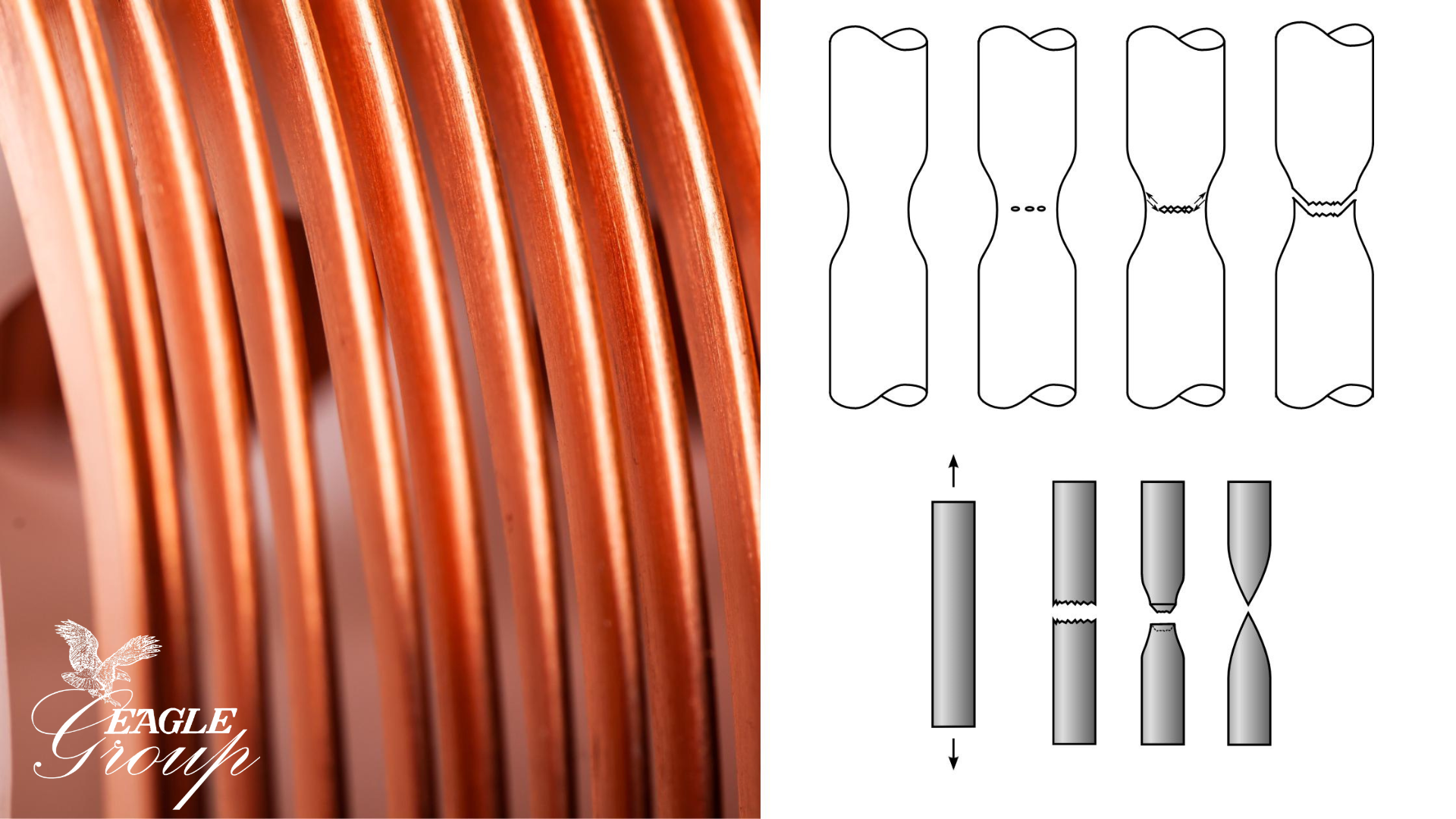

Metal Properties: Ductility

Ductility describes a metal’s amenability to being drawn or stretched without breaking. It is one of the crowning mechanical properties of a metal. Without a sound understanding of the science of ductility, manufacturers would be unable to guarantee the safety of their machinery.

In this blog, we’ll explain why manufacturers rely on ductility to guide them in casting parts that uphold integrity in service while protecting machinery against catastrophic failure.

Metal Properties: Strength

Past civilizations had practical reasons for caring about metal properties. They asked questions like “Can I break my enemy’s sword before he breaks mine?” or “How thick does my armor need to be to provide enough protection?” These warriors had a vested interest in material strength.

Tags: Metals, Metallurgy, Metal Properties, Mechanical Properties

Overview of Mechanical Properties of Metals

In the metal manufacturing industry, mechanical properties play a huge role when choosing the right alloy for each job. Throughout casting and machining processes, as well as during the product's useful life, the chosen material will be subject to many external forces. It’s up to the manufacturers to create products that perform as needed every step of the way. By understanding mechanical properties, manufacturing professionals can make the right choices for materials and processes.

Tags: Materials, Metals, Metallurgy, Metal Properties, Mechanical Properties