Keeping Castings Made in America: Supporting the American Foundry Industry through Entrepreneurship

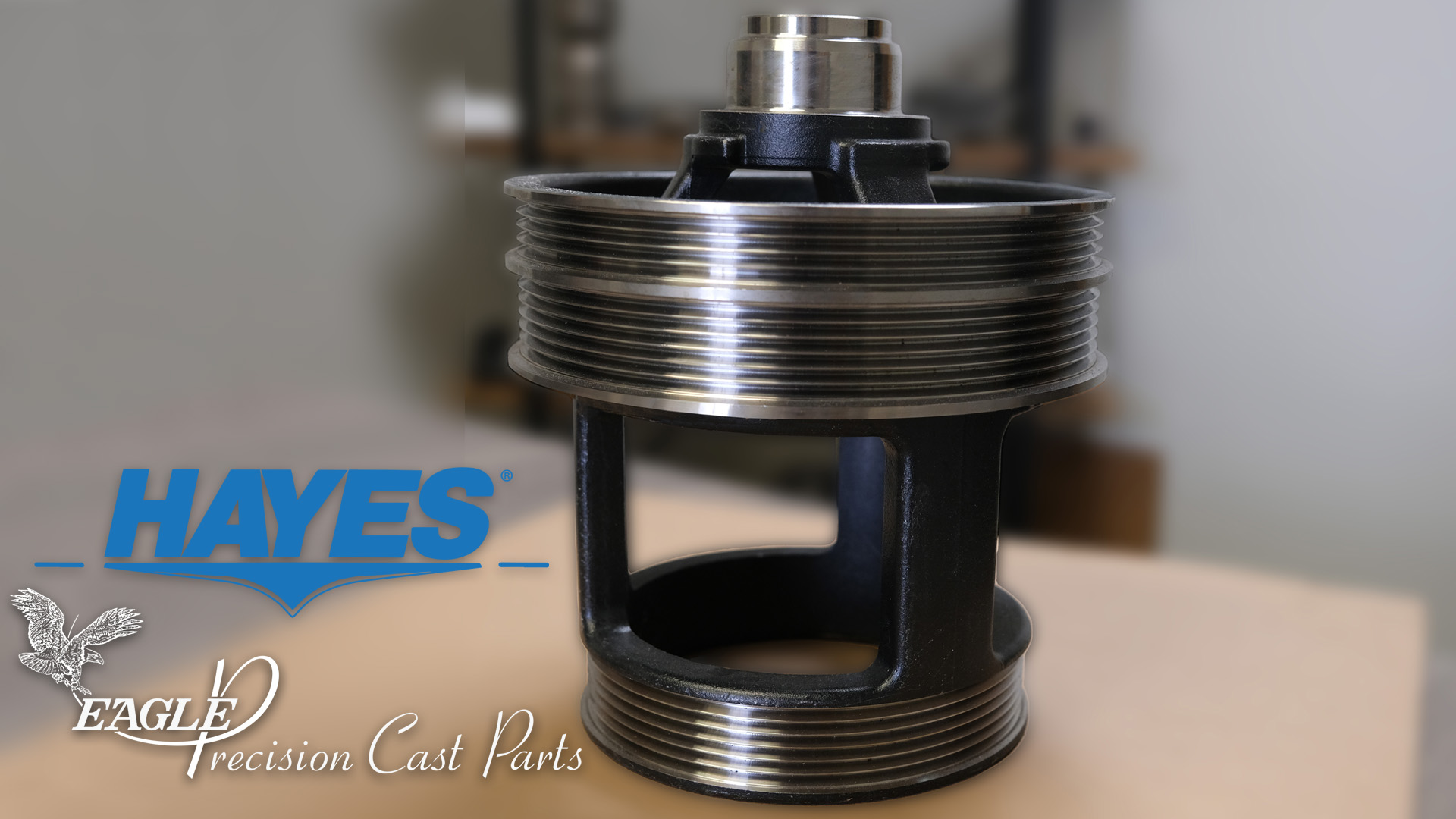

The Eagle Group is a team of manufacturing companies based in Muskegon, MI, made up of three foundries and a machine shop. Eagle Alloy, Eagle Aluminum, Eagle Precision and Eagle CNC are connected through common ownership and through common goals: while each company occupies its own niche, they often work together to provide “concept to completion” manufacturing. Beyond these four companies, Eagle Group’s owners also have stakes in OEM companies that utilize the Eagle Group’s services, but occupy altogether different spaces in the manufacturing world.

Tags: Case Study

Miracle in Muskegon: How the Eagle Group Replicated a MiG 17F Fighter Jet Fuel Cap in Two Days

When a star jet pilot had a missing fuel cap at the Muskegon Air Show, the Eagle Group stepped in to replicate the part in less than 48 hours.

Wings Over Muskegon took place in July, 2023 at the Muskegon County Airport. This interactive aviation experience was a revamped version of the Muskegon Air Fair, and marked the first event of its kind held in Muskegon in 17 years. Spectators enjoyed aerial acrobatics, flybys from iconic planes like the B-52 Flying Fortress, and even rides in WWII-era planes and Vietnam-era helicopters. Our very own John Workman, Eagle Group co-chairman of the board, performed at the event with his formation flying team, the Hooligans.

Tags: Case Study

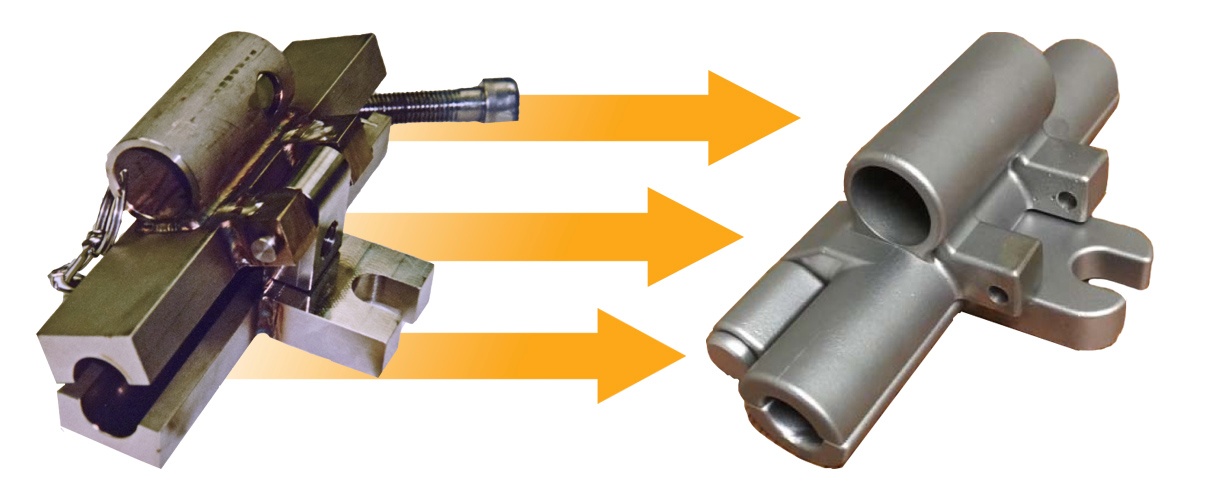

Case Study: Converting a Fully Machined Part to an Investment Casting

Manufacturers are aware of the benefits of machining: trained machine shops can produce complex parts with tight tolerances and all critical surfaces to spec. However, many manufacturers are learning that investment casting can produce cast parts to near-net shape, resulting in a host of benefits.

The machining process is often seen as the only way to manufacture a part with highly demanding specifications. Operating under this assumption, manufacturers sometimes choose to machine default without exploring other options. It’s also common for parts to be ‘over-toleranced,’ meaning they’ve been designed with tighter tolerances than the application actually calls for.

Hydrant Guard Case Study: Concept to Completion Manufacturing by The Eagle Group

The Eagle Group is not the kind of manufacturing partner that turns away a challenge. When we were approached with a design that could revolutionize the American water industry, we pulled together our entire suite of knowledge, resources, and experience to turn a brilliant idea into a viable product.

The case of Hydrant Guard demonstrates a strong example of inter-company cooperation between Eagle CNC Technologies, Eagle Alloy, Eagle Precision Cast Parts and our customers. By leveraging the best of what each company has to offer, the Eagle Group was able to take the Hydrant Guard design to the next level, ensuring not only that it would work as required, but that it would stand head and shoulders above competitors.

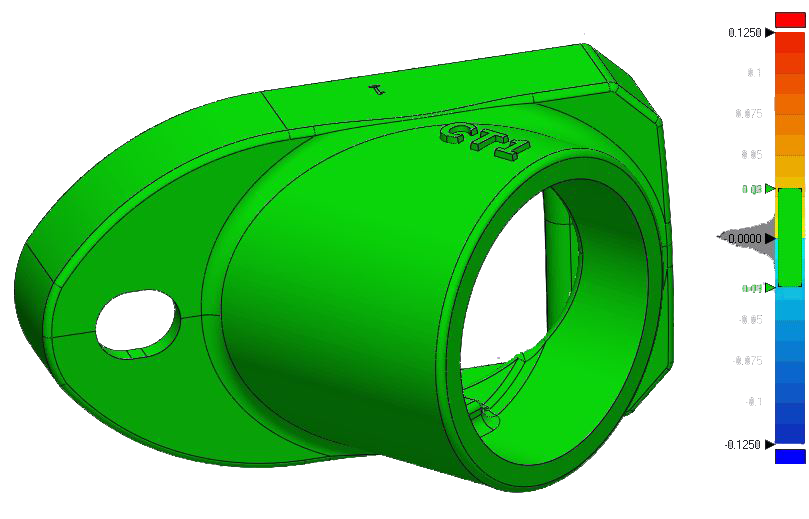

Finding the Perfect Balance: Case Study of Continuous Improvement in Cast Aluminum Fan Propeller Inspection

Eagle Aluminum specializes in permanent molding and greensand casting of aluminum products. In keeping with the Eagle Group's philosophy of continuous improvement, Eagle Aluminum's team is always looking for ways to improve our processes to achieve better quality, greater efficiency and reduced returns. This case study focuses on a recent innovation that dramatically improved the return rate for a line of parts without adding to processing time.

Case Study: Reverse Engineering Cast Products on an Expedited Timeline

Cem-Tec, a manufacturer of steel light poles in business since 1974, approached Eagle Alloy, Inc. with an emergency order. Due to an unforeseen supply-chain issue, they needed to find a new foundry to manufacture one of their popular products. With orders in and customers waiting, the clock was already ticking.

The following case study illustrates the steps Eagle Alloy followed to transfer casting of the product to our facility and to ensure that Cem-Tec had high-quality products ready for their customers as soon as possible.

Tags: Eagle Alloy, Case Study, Product Design, Development, Product Development

Case Study: Lean Manufacturing at Eagle Alloy

Eagle Alloy, Inc. was founded in 1979 and quickly grew from a short-run facility to a medium-to-high-production steel foundry. Despite the company’s success, its founders were not satisfied with the status quo. Having heard of developments in lean manufacturing, they decided to implement these tools in hopes of achieving greater efficiency, stability and quality throughout the production process.

5S: The Beginning

As with many production facilities beginning to experiment with lean manufacturing, Eagle Alloy started with 5S. 5S is easy to adapt to just about any environment, and the key to lean is customization. Every lean tool must be adapted to the particular type of production, to the size of the company and to the facility's space.

Tags: Lean Manufacturing, Eagle Alloy, Case Study

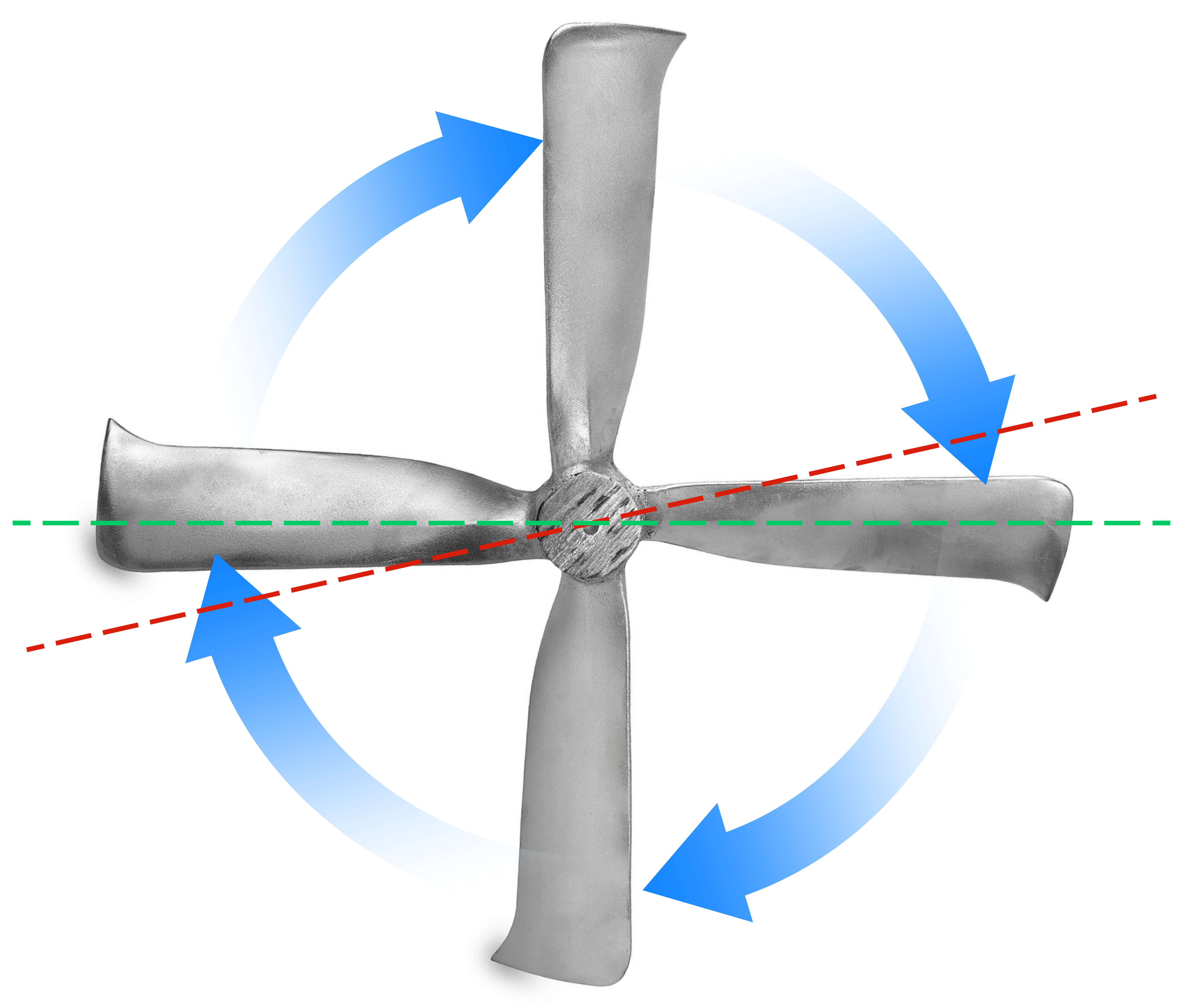

Aluminum Casting in Practice: A Case Study of Cast Aluminum Fan Blades

A major manufacturer of ventilation systems contacted Eagle Aluminum Cast Products, Inc. when demand was growing and they were ready to make a change.

The customer had already been producing 48” fan blades for agricultural use through green sand casting, but they’d outgrown that method. Demand projections suggested that permanent mold casting would yield lower per-part costs, with the added benefit of greater consistency.

Years later, EACP still produces fan blades for the customer through the process of permanent mold casting. Demand has increased even more, and product offerings have become more diverse. Read on to learn how EACP handles the design, production and delivery of this cast aluminum fan blade.

Tags: Aluminum Casting, Aluminum, All About Al, Case Study, Eagle Aluminum

One Part's Journey from Fabrication to Casting

It all started on a routine facility tour

While touring a client’s facility, representatives of Eagle Precision Cast Products noticed a cable clamp assembly–a relatively complex fabricated part that they believed would be an excellent candidate for fabrication to casting conversion.

Tags: Metalcasting, Processes, Fabrication to Casting, Fabrication, Fab-Casting, Investment Casting, Case Study