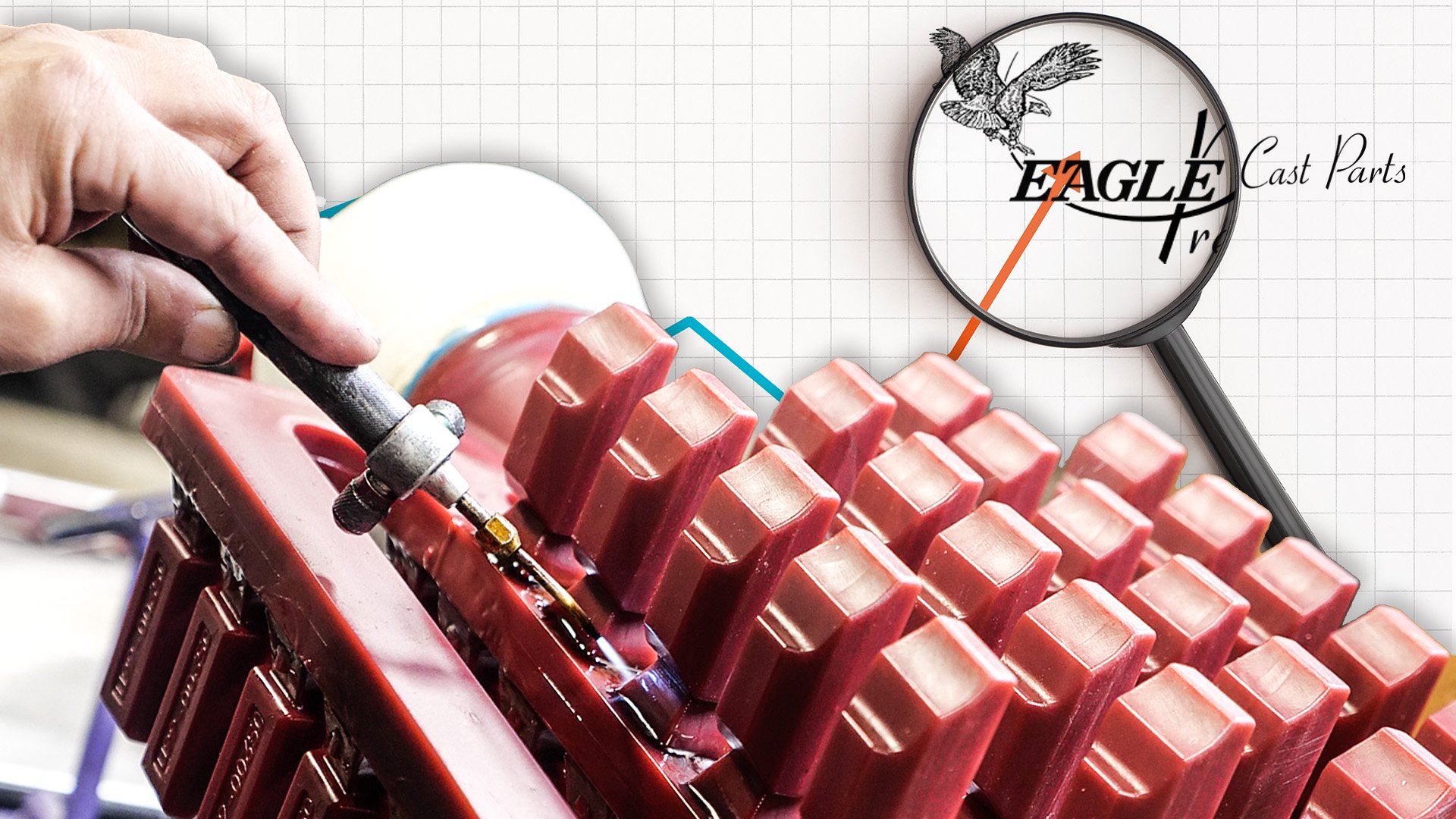

Continuous Improvement at Eagle Precision: Optimizing the Investment Casting Wax Room

This article is part of our series: Continuous Improvement at Eagle Precision

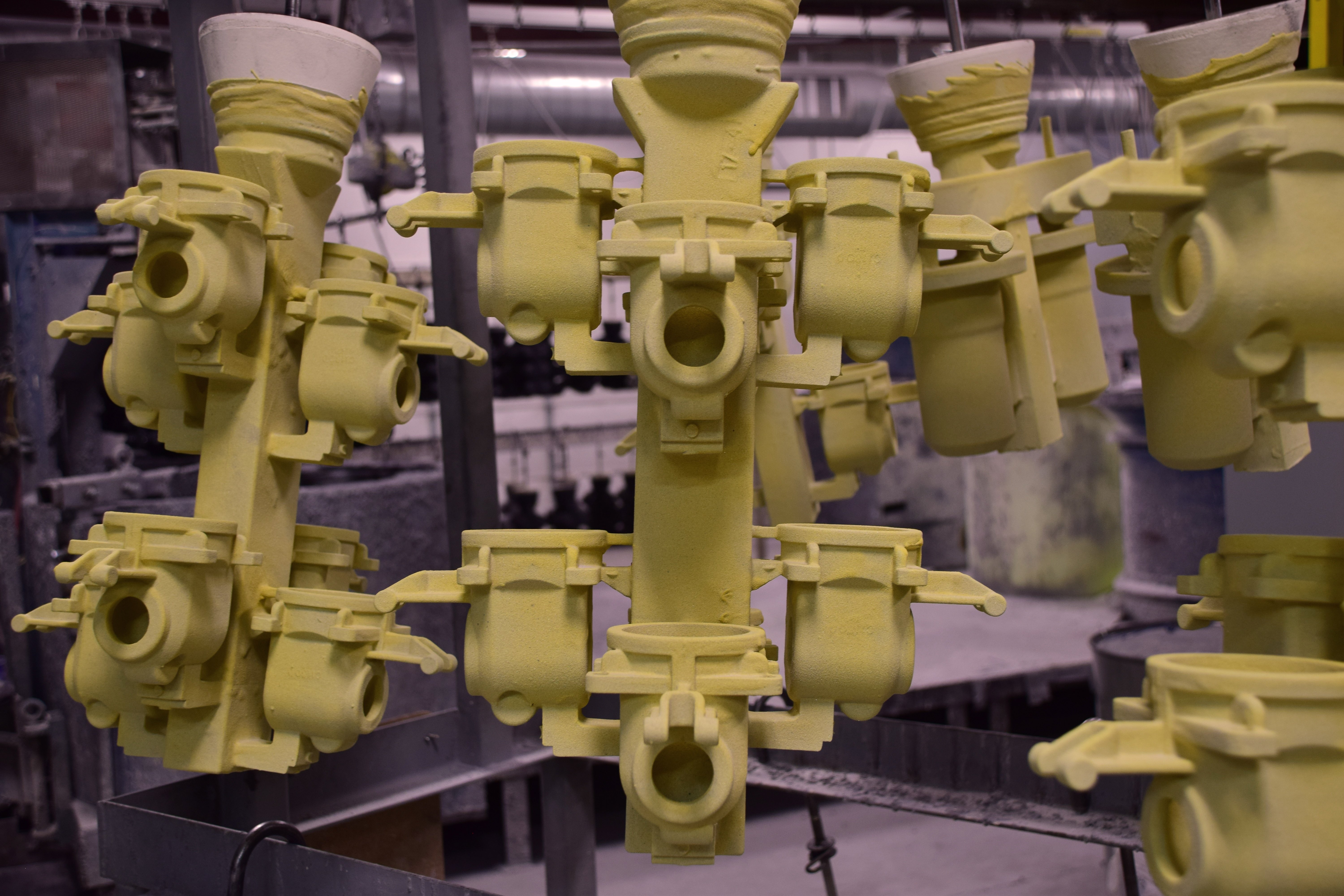

The wax room is at the heart (and start) of our investment castings. By injecting the wax room with fresh ideas, we’ve been able to greatly improve our pouring efficiency, leading to higher production yields, less downtime, reduced remelting rates, and faster delivery times.

Tags: Lean Manufacturing, Investment Casting, Eagle Precision, Continuous Improvement

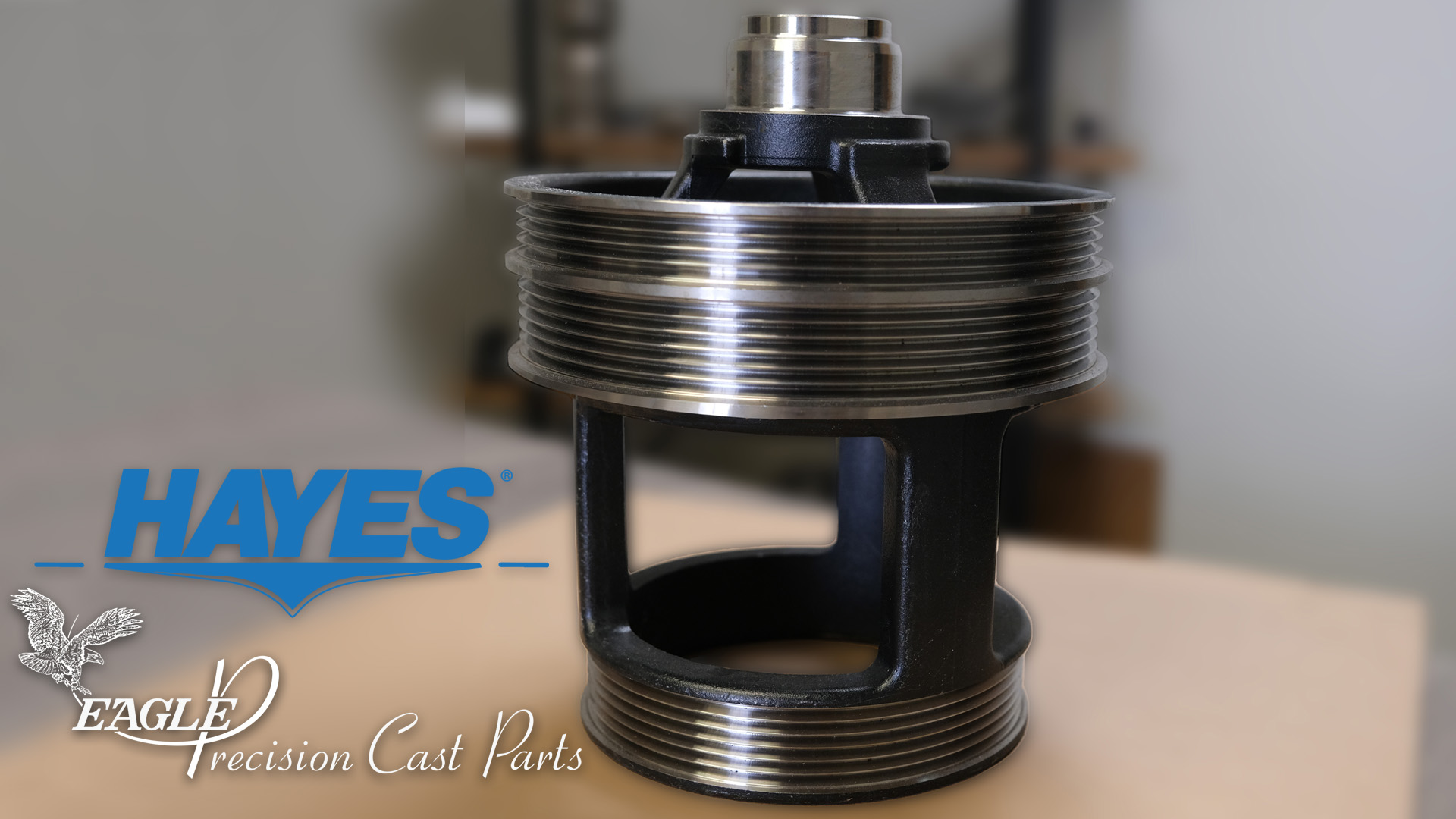

Case Study: Converting a Fully Machined Part to an Investment Casting

Manufacturers are aware of the benefits of machining: trained machine shops can produce complex parts with tight tolerances and all critical surfaces to spec. However, many manufacturers are learning that investment casting can produce cast parts to near-net shape, resulting in a host of benefits.

The machining process is often seen as the only way to manufacture a part with highly demanding specifications. Operating under this assumption, manufacturers sometimes choose to machine default without exploring other options. It’s also common for parts to be ‘over-toleranced,’ meaning they’ve been designed with tighter tolerances than the application actually calls for.

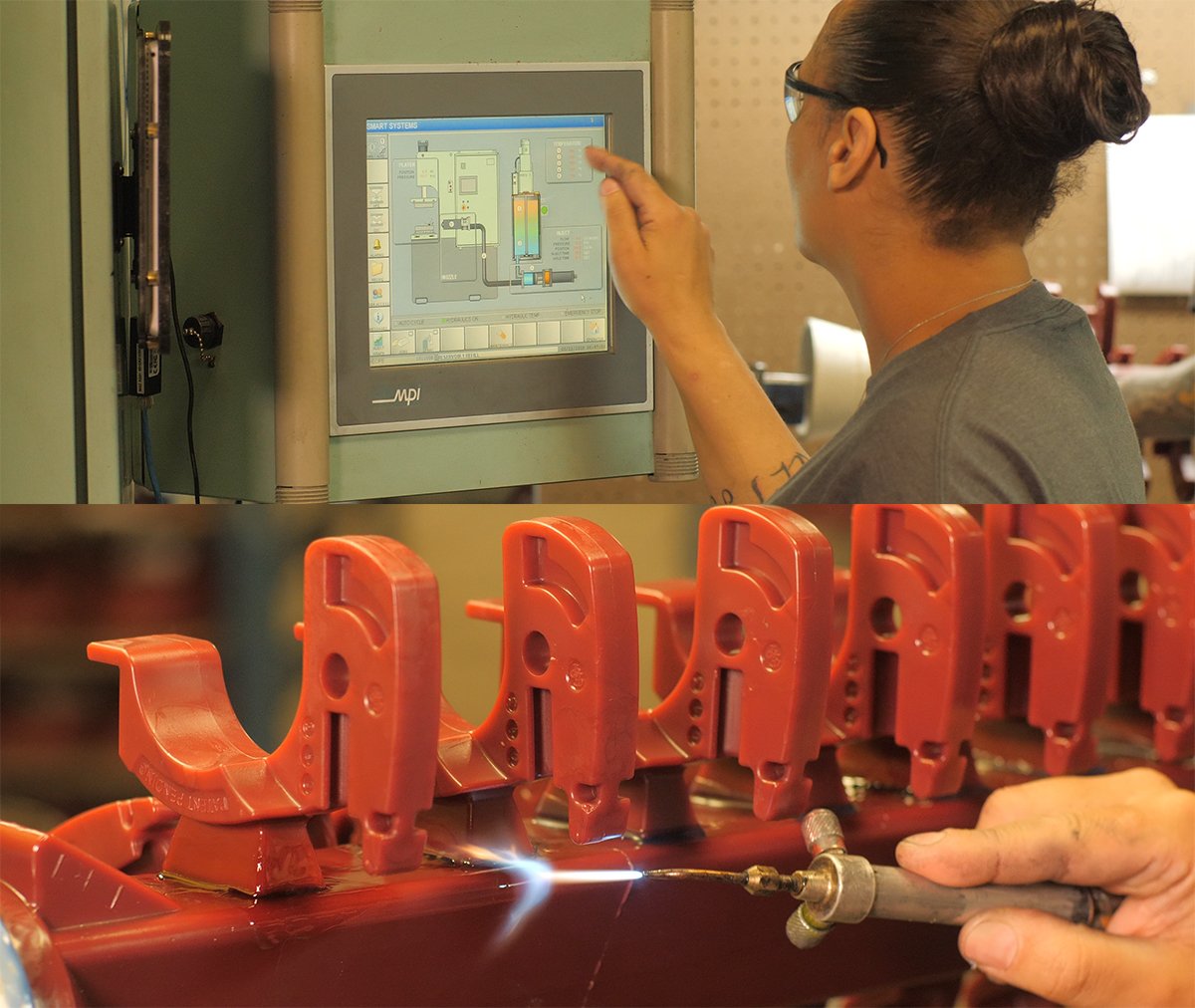

Robotics in Investment Casting

Our investment casting foundry, Eagle Precision, makes use of robotics in two steps of the casting process. We started with a robotic dipping cell and expanded into two, followed by a third robotic cell that specializes in after-cast grinding. While robotic cells like these do require a large up-front investment, we’re already seeing company-wide benefits resulting from our use of robotics in investment casting.

Robots are becoming more and more common throughout the manufacturing industry, and investment casting is no exception. According to John Scott, VP of Sales at Buntrock Industries, the investment casting industry is seeing increased demand for robotics for three reasons: “lack of workforce availability, desire for increased process control and productivity, and improved health and safety.”

Tags: Investment Casting, Eagle Precision, Robotics, grinding

The Benefits of Machined Part to Casting Conversion

Metalcasting is a highly versatile manufacturing process. In fact, many manufacturing professionals are not aware of just how versatile it is, and they continue to produce parts through other less efficient methods. While there is certainly a necessity for fabrication and machining in the metal manufacturing world, these processes can sometimes be replaced by casting.

Tags: Machining, Investment Casting, Productivity, Eagle Precision

Tooling for Investment Casting

Tooling in metalcasting and CNC machining refers to reusable items that are specific to each job. In investment casting, tooling is considered to be wax-injection dies used to create wax patterns. If you're familiar with how investment casting works, you already know that these wax patterns form the basis of the investment casting process. Each part begins as a wax pattern, and the properties of wax – smooth surface, low melting temperature and excellent flow properties – that make highly complex investment castings possible.

Tags: Investment Casting, Tooling

CAST IN STEEL: Student Teams Compete to Cast the Best Steel Viking Axe

This year the Steel Founders' Society of America (SFSA) introduced a national competition to engage students with steel casting and help foundries connect with the next generation of manufacturing professionals. Inspired by History Channel's Forged in Fire, the Cast in Steel competition brings teams of engineering students from around the country together to find out who can cast the best Viking axe. Testing, judging and awards took place prior to CastExpo in Atlanta, GA.

Tags: Investment Casting, Eagle Precision, Airset Casting, Event, Student Metalcasting Competition, CastExpo, Trade Associations

How Investment Casting Compares to Other Metalcasting Methods

Tags: Metalcasting, Processes, Investment Casting

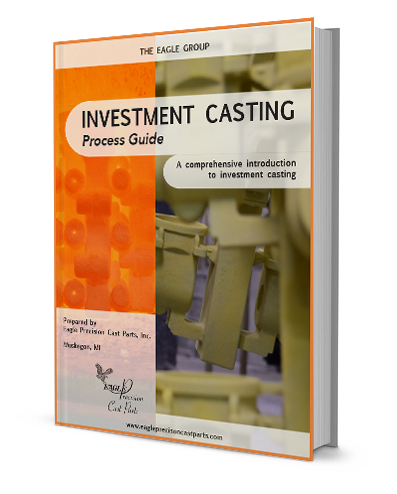

Investment Casting Guide Ebook: New Eagle Group Resource for Manufacturers

Eagle Precision Cast Parts, Inc. just released a downloadable resource, titled Investment Casting Process Guide: A Comprehensive Introduction to Investment Casting.

The goal of the 21-page ebook is to make it easy for manufacturers, and anyone else who's interested, to learn the basics of investment casting. Manufacturers looking for a better way to produce parts can find information on tolerances, design recommendations and a full case study.

Tags: Metalcasting, Investment Casting, Eagle Precision, Investment Casting Guide

How the Investment Casting Process Works

Investment casting, sometimes known as lost-wax casting, is a metal forming method known for its ability to produce parts with tight tolerances, complex inner cavities and accurate dimensions.

As we discussed in our Introduction to Investment Casting post, the basic technique has existed for millennia. Over the years, innovations in equipment and methodology have kept pace with demand. Today, investment casting is one of the most popular forms of metal casting.

Read on to learn more about the unique process of investment casting.

Tags: Metalcasting, Processes, Investment Casting, Eagle Precision

Introduction to Investment Casting

Investment casting is nearly as old as metalcasting itself, with the earliest known examples dating back to 3,500 BC. Before investment casting was invented, metal castings were created using open stone or ceramic molds. Investment casting allowed for much greater detail and smoother finish, vastly expanding the possibilities of metal casting.

Today, investment casting is one of the most versatile methods of metal casting. The process, which is still similar to that used over 5,000 years ago, allows for tighter tolerances, more intricate shapes and smoother surface finishes than other metal casting methods.

Tags: Metalcasting, Processes, Investment Casting, History