Michigan Manufacturers Honor Veterans by Reviving a Sunken Patrol Boat

Collaboration Between Casting and Machining to Re-Engineer a Lost Component of a Vietnam-Era Patrol Boat

Muskegon-based manufacturers Eagle CNC and Eagle Alloy put their capabilities to the test when they set out to replicate a key component of a Vietnam-era patrol boat as a steel casting. For the team behind the casting, this project is about more than fixing a boat; it’s about preserving history, honoring the legacy of those who served and sacrificed, and ensuring their stories continue to be told for generations to come.

Tags: Eagle Alloy, CNC Machining, Eagle CNC, 3D Scanning, Reverse Engineering, 3D Printed Molding

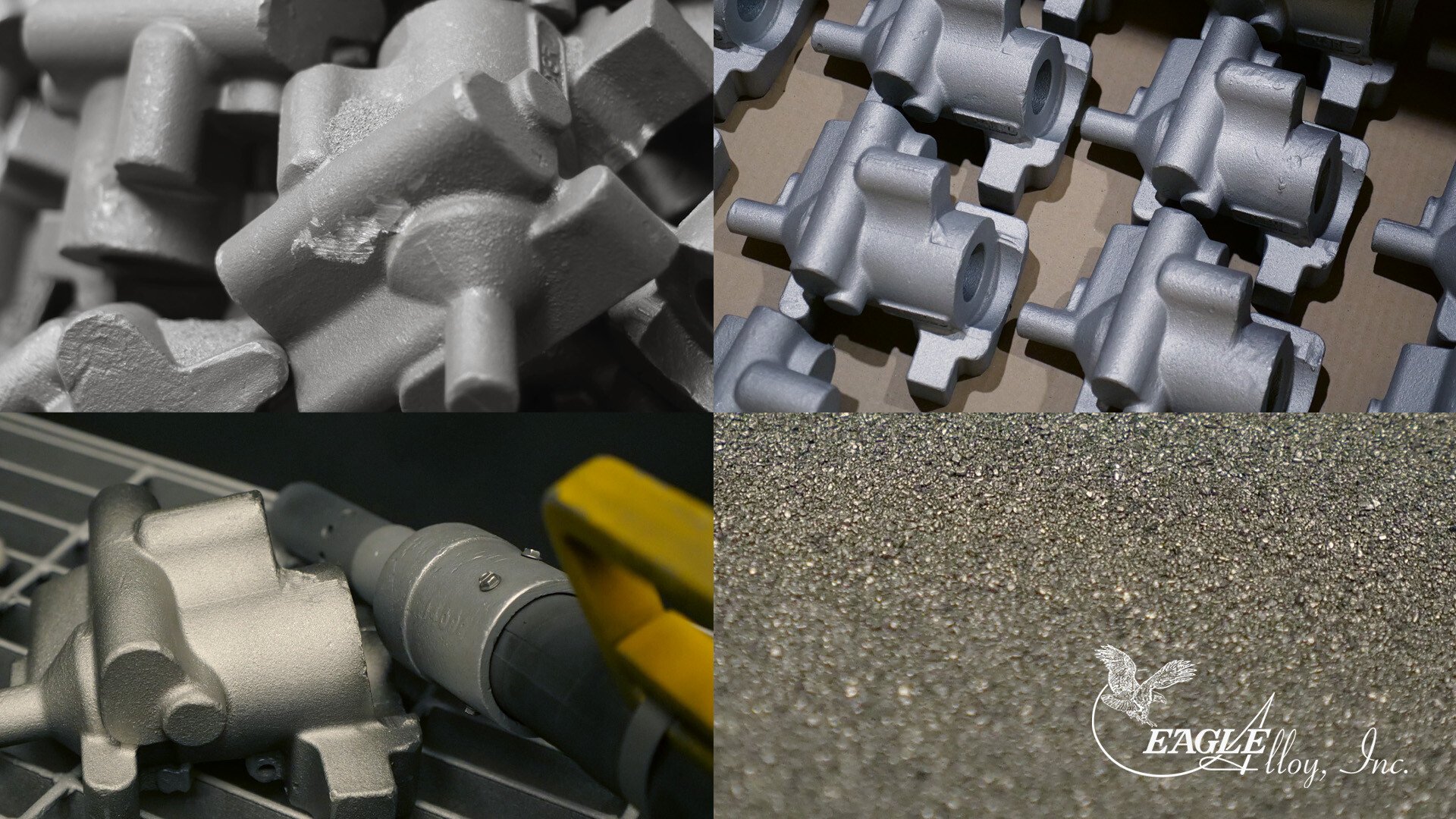

After Casting: Perfecting the Blasting Process

After a casting solidifies in the mold, the part undergoes a number of post processes to prepare it for delivery. One of the most commonly used post processes is blasting, an intensive cleaning process that removes debris and excess material from castings. At the Eagle Group, blasting plays a pivotal role in prepping casting surfaces for delivery or for further processing. Our latest investment in state-of-the-art stainless-steel grit and an optimized media blasting process is paying dividends for our customers and our employees by providing cleaner parts, less oxidation, and a safer workplace.

But getting to this point has been a years-long journey. Here's how we got here.

Tags: Lean Manufacturing, Eagle Alloy, Equipment, Continuous Improvement, Blasting

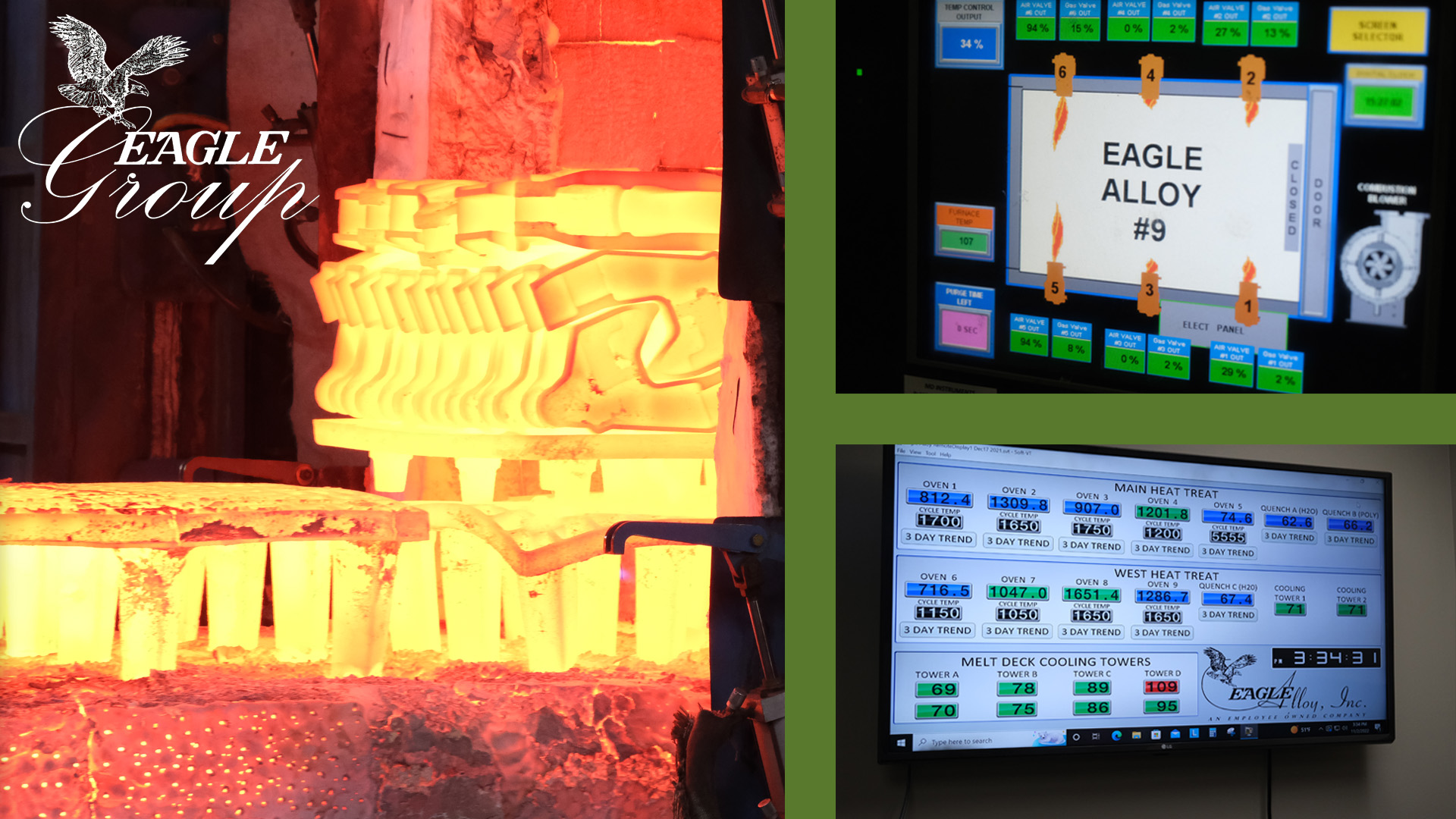

Heat Treatment for Cast Products at Eagle Alloy

Eagle Alloy provides a wide range of metalcasting services. In addition to casting hundreds of alloy grades that can be formed into virtually any castable shape, our foundry is fully equipped to heat treat the majority of parts we manufacture. In this blog, we’ll be opening the doors to our heat treatment facilities. You’ll get to know what kind of heat treat equipment we utilize to deliver superior products that consistently meet performance expectations.

Casting a part into its required shape does not fully prepare it for a life of service – only heat treatment can ensure a part performs exactly how it should. With the exception of a handful of nickel-based specialty alloys, Eagle Alloy heat treats just about every part that is cast in our facilities. From annealing and normalizing to stress relieving and quenching, we have the furnaces, quench tanks, data and expertise to take a product from inception to delivery.

Tags: Eagle Alloy, Metallurgy, Heat Treatment

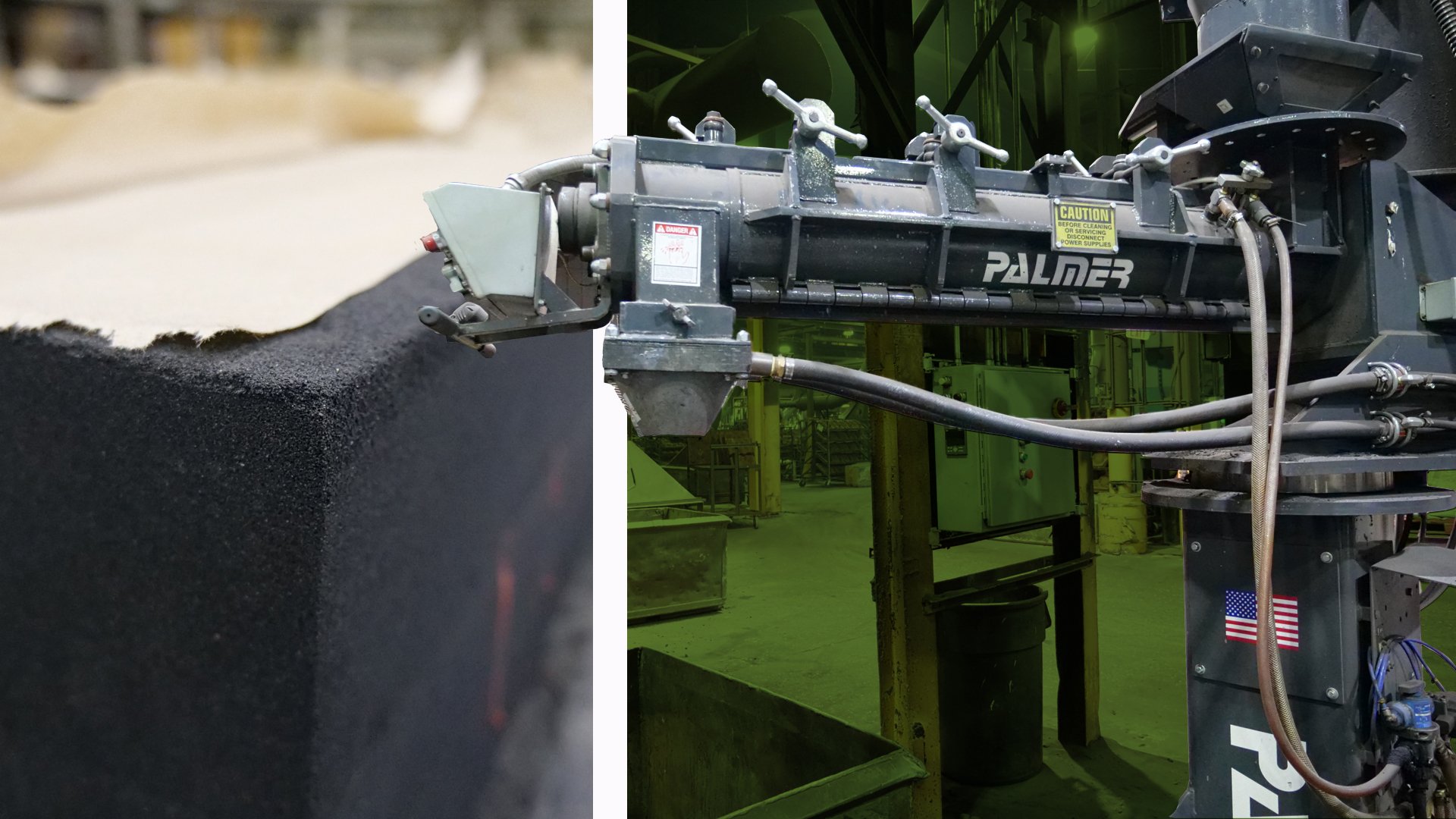

Eagle Alloy Upgrades Casting Facilities with New Airset Sand Mixer

The Eagle Group produces a wide variety of cast and machined products for many industries. One of our strengths as a company is our ability to employ different casting processes. Eagle Precision Cast Parts, for example, specializes in investment casting, and Eagle Alloy specializes in shell molding. When you tour the shop floor at Eagle Alloy, you’ll see our shell molding machines busy at work, turning out most of our order flow. But that’s not all we do: Eagle Alloy also houses a robust airset (no-bake) molding line to support our shell customers.

Tags: Eagle Alloy, Airset Casting, Facilities, Equipment

Improving Casting Production with In-House Robotics Expertise

In many ways Dakota Hanson (above) is a typical Young Millennial: he's an avid Tik Tok fan, spends his spare time playing Call of Duty, and has a job working with cutting-edge technology. However, unlike many members of his generation, Dakota's workplace is more than a laptop and a WIFI connection. As an Engineering Technician at Eagle Alloy (a shell molding facility in Muskegon, MI) Hanson specializes in programming robotic cells that play an integral role in the manufacturing process.

In fact, Eagle Alloy has a growing number of employees whose job descriptions include programming and operating robotic cells. Through a continuing education program led by robotics manufacturer ABB, Eagle Alloy has been able to provide its in-house team with manufacturing robotics expertise, further improving the company’s response time and resilience.

Tags: Eagle Alloy, Capabilities, Technology, Robotics, grinding, Employees

Congratulations to Eagle Alloy's First Class of Master Foundrymen

Eagle Alloy's new internal certification program recognizes the skill and dedication of our top-performing employees. The Master Foundryman certification will be awarded every quarter based on objective measures of experience and productivity. The first Eagle Alloy Master Foundrymen, awarded following Q1 2021 performance reviews, have demonstrated consistently outstanding performance in all aspects of their jobs.

Tags: Eagle Alloy, Employees

New Video Resource: Shell Molding Process 3D Animation

Eagle Alloy, Inc. is proud to present our latest tool for metalcasting education. Our updated shell molding animation provides a start-to-finish overview of the shell mold casting process.

Tags: Shell Molding, Eagle Alloy, Introduction to Shell Molding

Revamped Facilities Reflect Our Mission

Eagle Alloy's revamped facilities include a brand new cafeteria that facilitates social distancing, locker rooms with showers, and a new and improved health clinic. Completed in summer of 2020, these improvements make Eagle Alloy an even better place to work, and an even more reliable partner in the metal casting industry.

Tags: Eagle Alloy, Facilities, Human Resources

Imagine a World Without Steel Casting Supply Issues

We don't have to say how good we are. Our customers do it for us!

Every six months, Eagle Alloy invites customers to fill out a survey rating their satisfaction with our services. We ask about every aspect of the supplier-customer relationship, from answering phone calls and emails to on-time delivery. Our company was founded in 1979 with a goal of providing high-quality castings and superior customer service; customer feedback is invaluable to us as we seek to better align our activities with our guiding principles.

Tags: Eagle Alloy, Testimonials

Eagle Alloy Unveils New Customer Training Center

MUSKEGON, MI - MAY 27, 2020 – Eagle Alloy is proud to announce our newly completed Multimedia Training Center. This facility will allow us to provide our customers with state-of-the-art training to go along with our plant tours and project discussions. Groups of up to 24* can relax and take in training and introductory presentations by our Sales, Engineering, Quality and Production department staffs.

Tags: Eagle Alloy