Jason Bergman

Recent Posts

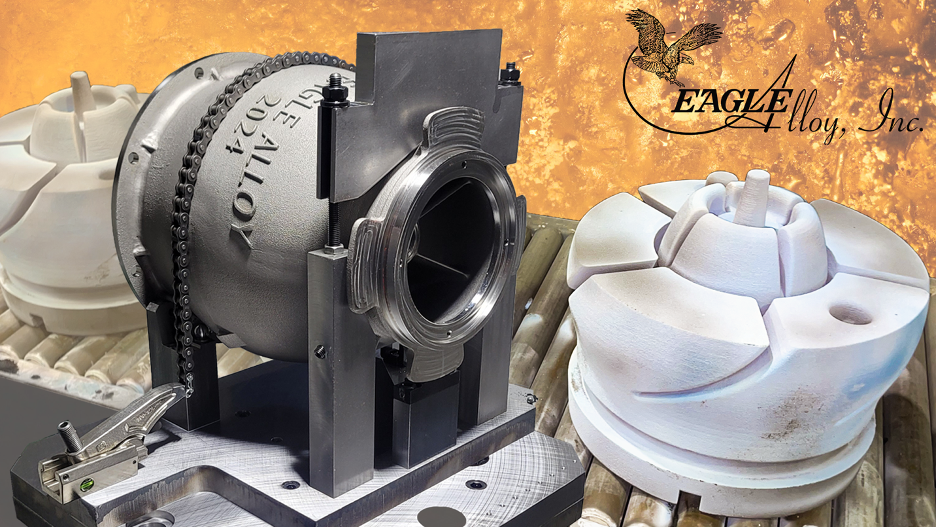

Rapid Prototyping for Castings: How Eagle Alloy Delivers High-Quality, Low-Volume Cast Parts on Tight Timelines

When time and flexibility are top priorities, rapid prototyping for castings offers manufacturers a fast-track route to producing complex cast parts in small quantities. At the Eagle Group, this advanced approach supports both prototype development and low-volume production, helping customers refine designs, verify performance, and move from concept to production quickly without the long lead times associated with permanent tooling.

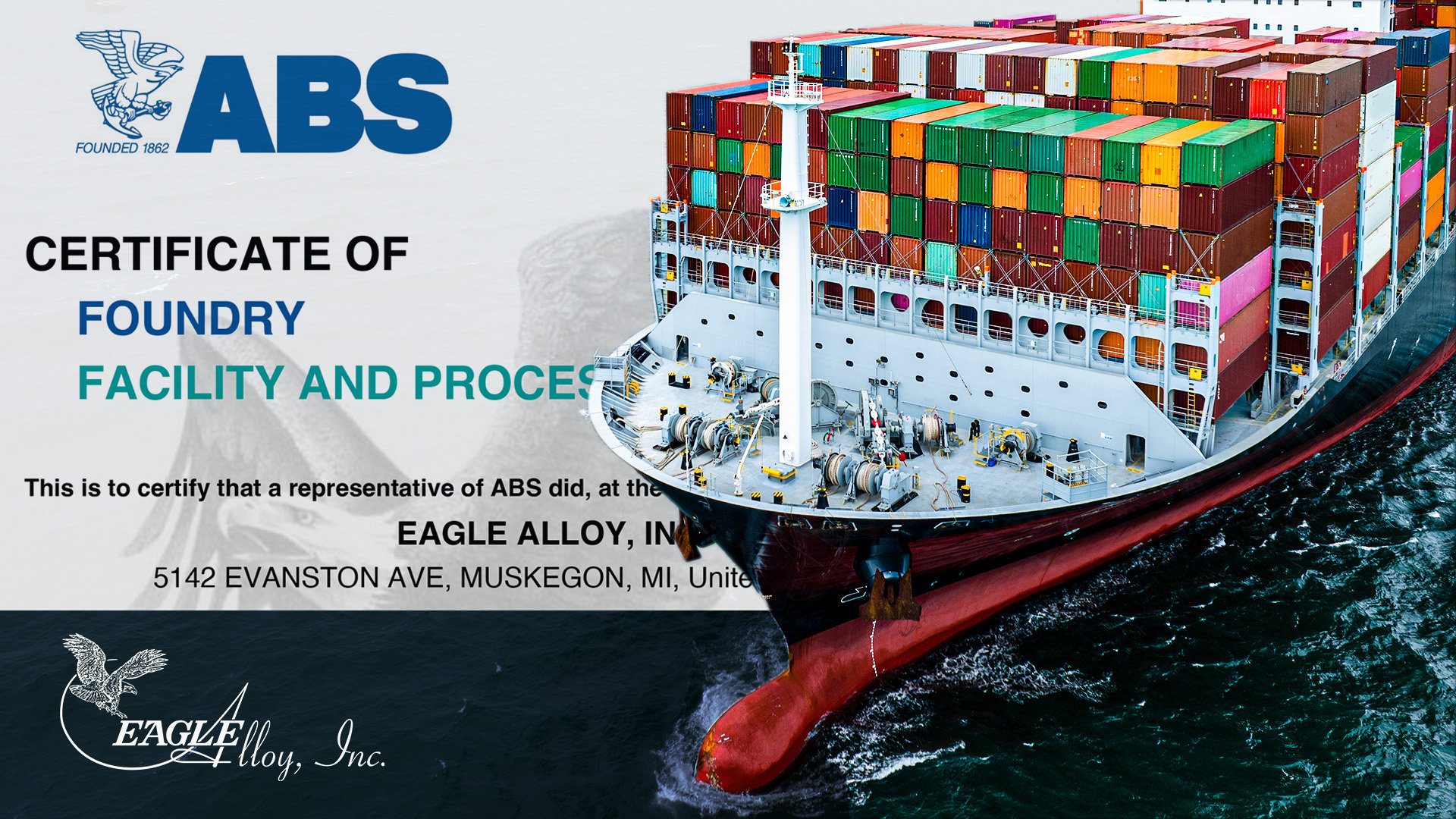

Eagle Alloy on the High Seas: Our American Bureau of Shipping (ABS) Certification

Recently, Eagle Alloy squared off against the demanding technical requirements and thorough audits of the American Bureau of Shipping’s “Type Approval” certification. Through this process, we demonstrated our commitment to producing marine-grade castings that meet the highest standards for safety and reliability in the maritime industry, as well as our willingness to go deeper in our readiness to provide uncompromising castings to the marine industry.

Tags: Certification, ABS, American Bureau of Shipping, Quality

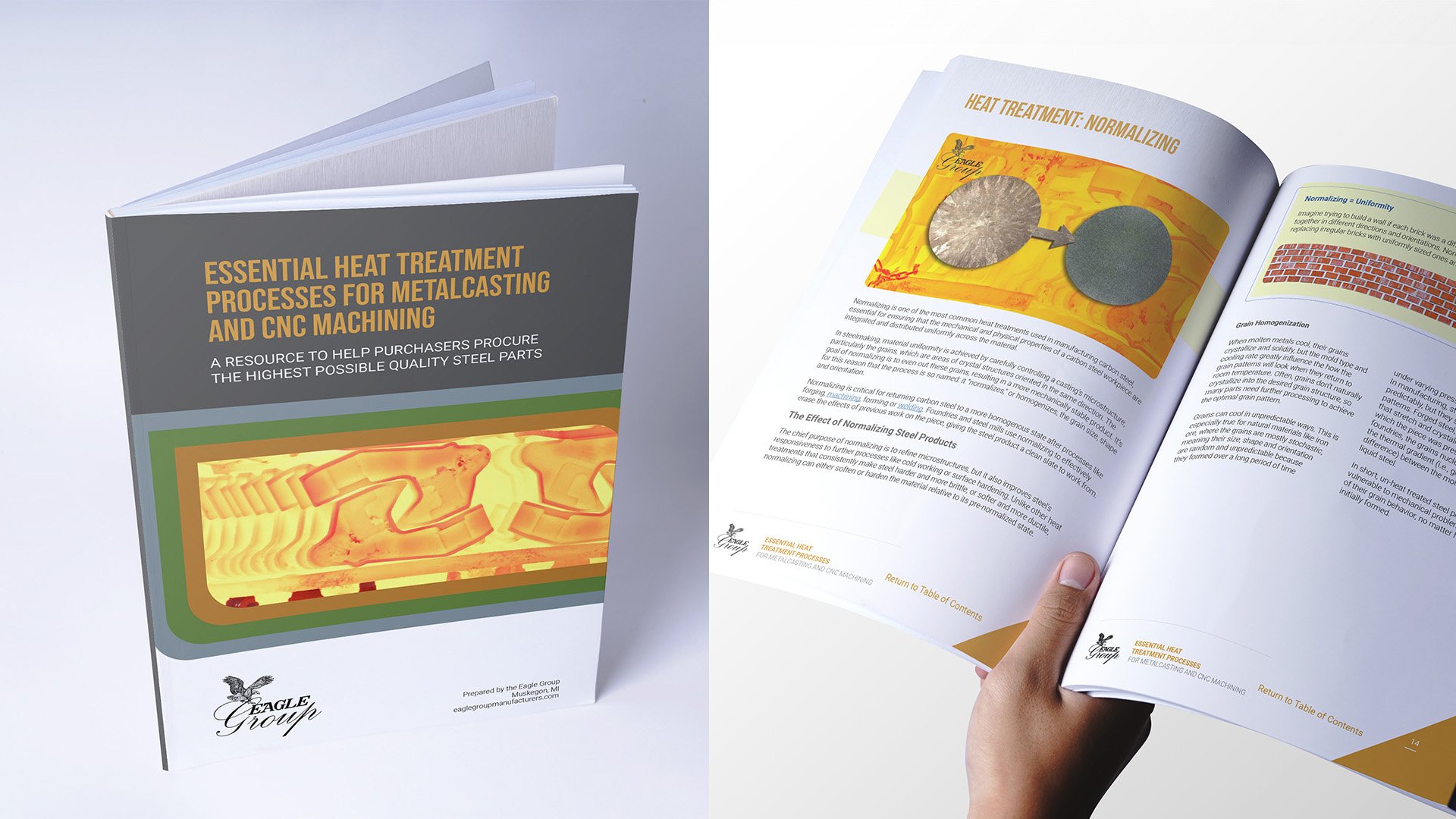

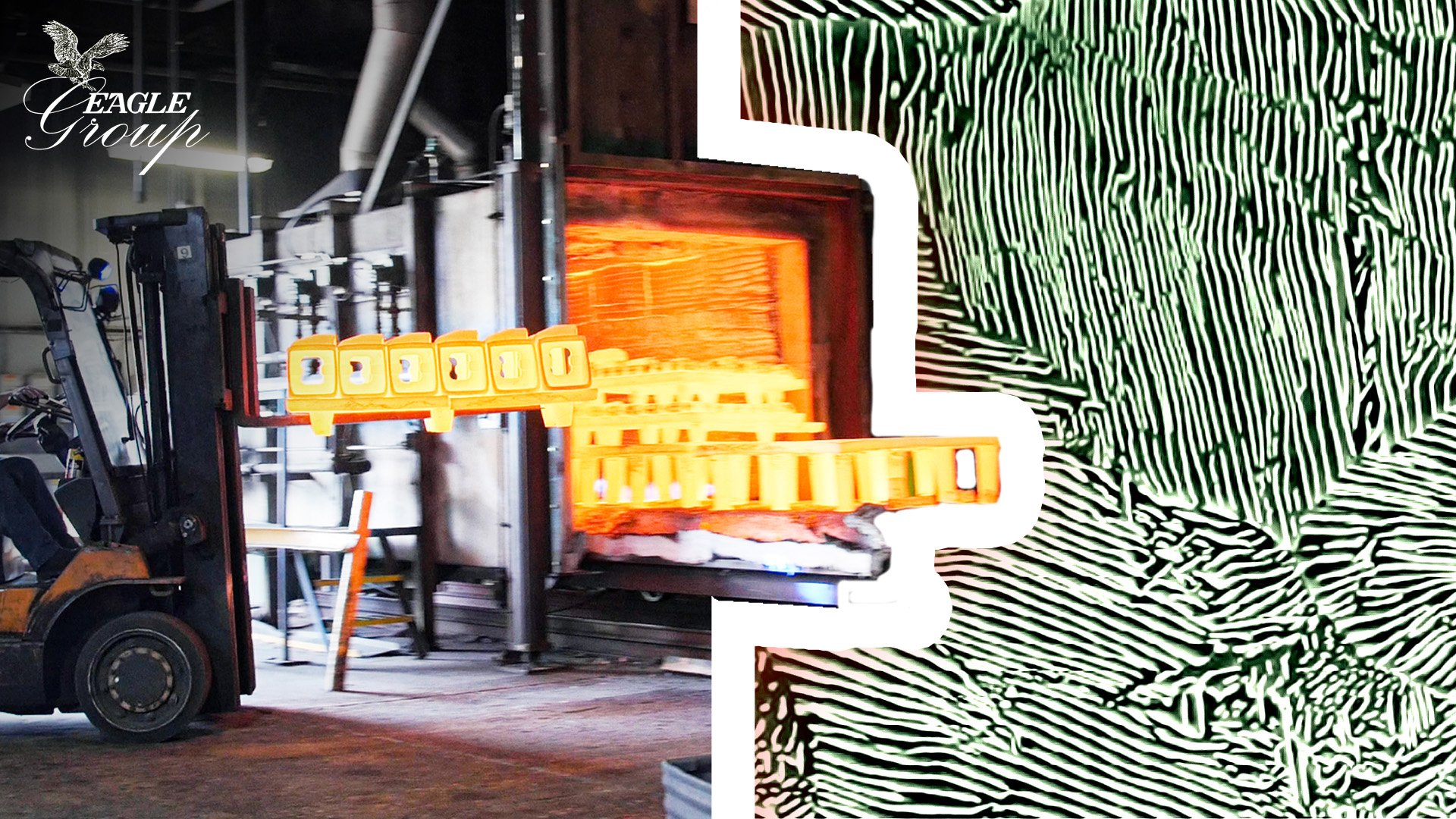

New Ebook: Heat Treatment Processes for Metalcasting and CNC Machining

The latest resource from the Eagle Group provides a comprehensive introduction to heat treatment in metalcasting and CNC machining.

This 40-page guide is available as a free download and is designed for manufacturing professionals, purchasers and engineers looking to deepen their understanding of heat treatment. It explores the role of heat treatment in enhancing the quality of cast and machined steel parts, ultimately helping purchasers procure the highest possible quality steel parts.

Tags: Heat Treatment

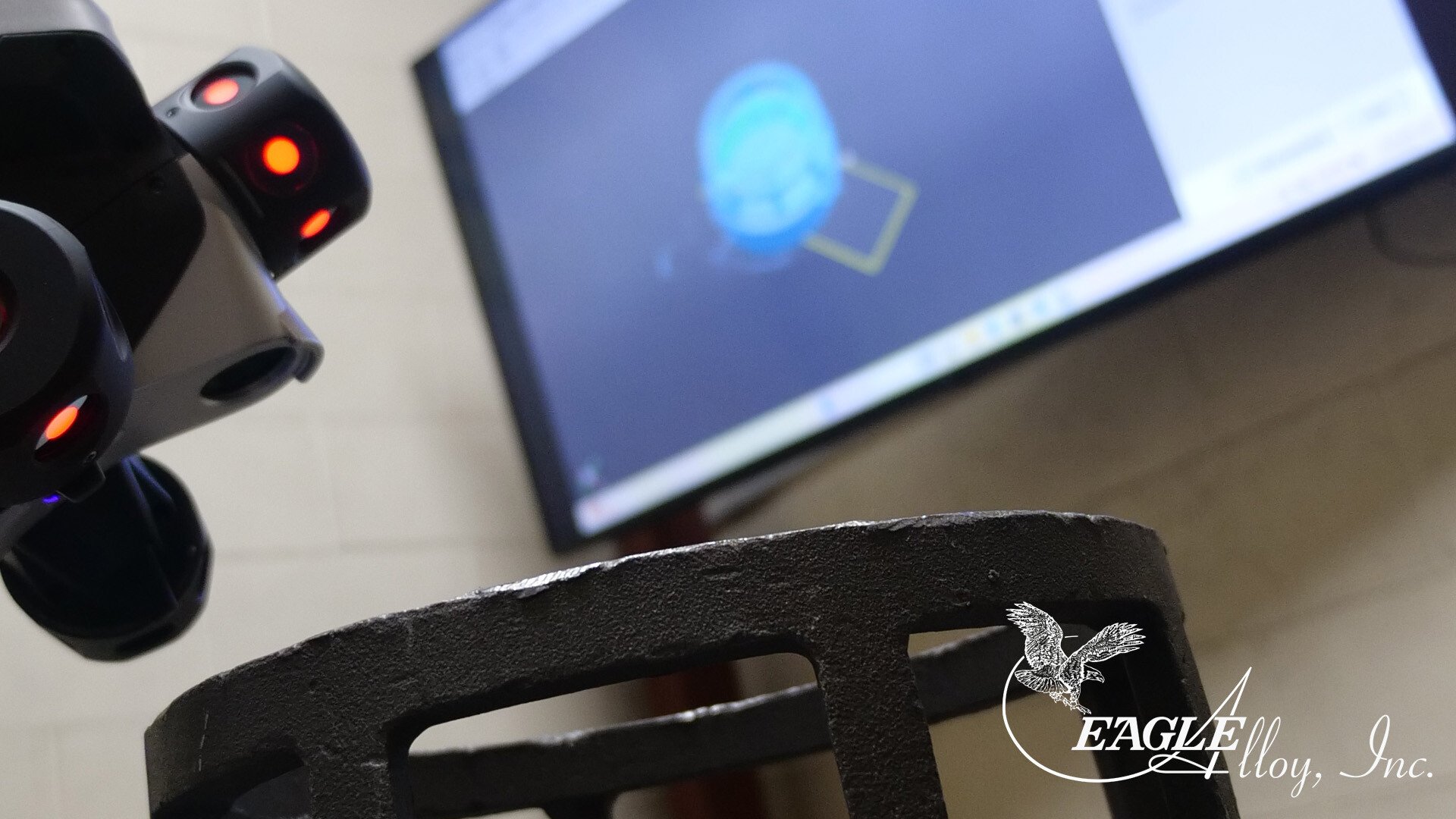

Beyond Quality Control: How Eagle Alloy’s Keyence WM-6000 Boosts Foundry Capabilities

The Eagle Group realized early on the value of 3D scanning for manufacturing. Eagle CNC, Eagle Precision and Eagle Alloy all utilize 3D scanning systems that optimize our capabilities not just for inspection, but also for reverse engineering and prototyping. For us, scanning is an integral part of the casting process.

That’s why Eagle Alloy has upgraded its Keyence scanner several times to stay ahead of the curve. Our latest model, the WM-6000, helps our shell-mold foundry deliver even more precise, reliable castings for our customers.

Tags: 3D Scanning

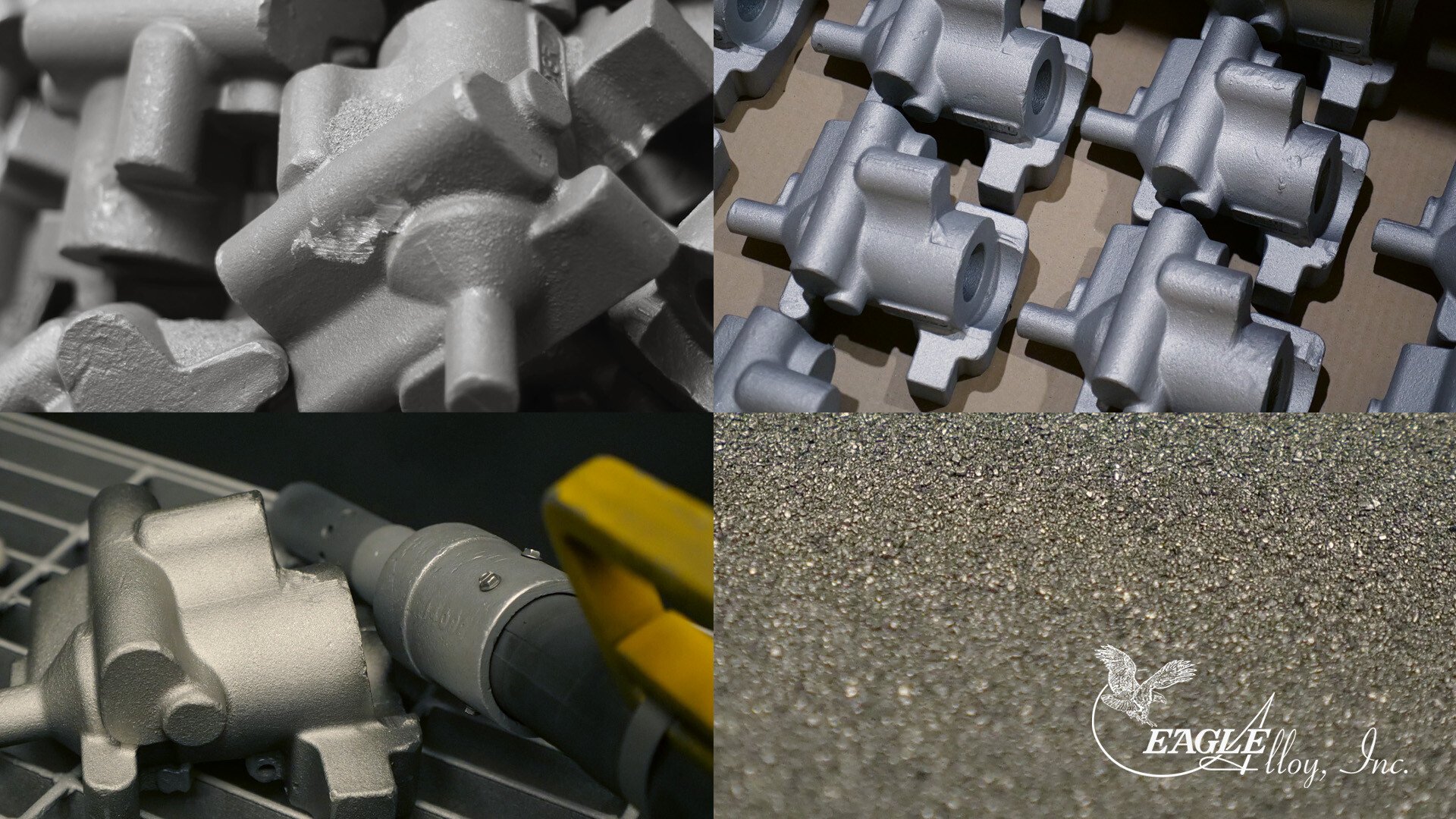

After Casting: Perfecting the Blasting Process

After a casting solidifies in the mold, the part undergoes a number of post processes to prepare it for delivery. One of the most commonly used post processes is blasting, an intensive cleaning process that removes debris and excess material from castings. At the Eagle Group, blasting plays a pivotal role in prepping casting surfaces for delivery or for further processing. Our latest investment in state-of-the-art stainless-steel grit and an optimized media blasting process is paying dividends for our customers and our employees by providing cleaner parts, less oxidation, and a safer workplace.

But getting to this point has been a years-long journey. Here's how we got here.

Tags: Lean Manufacturing, Eagle Alloy, Equipment, Continuous Improvement, Blasting

Heat Treatment: Tempering

The word ‘tempering’ generally means acting as a counterbalancing force, moving an object (or a situation) away from the extremes, toward a more balanced state. The same principle applies to heat treatment: when we temper a metal part, we are adjusting the proportion of one mechanical property against another. Specifically, we are increasing ductility while simultaneously decreasing strength and hardness.

Tempering is most often performed after a metal piece has been seriously stressed through hardening or after normalizing. When a material is hardened (especially quench hardened, the most common method of hardening), it is in an unbalanced state. In metallurgical terms, we say the metal is unstable: its molecules would like to rearrange into a more stable structure, but the quench hardening process freezes them before they get the chance. Likewise, the process of normalizing takes the steel molecules through a phase transformation, leaving stresses in its wake. (For a longer discussion of phase transformations, check out our Introduction to Heat Treatment for Cast Parts.)

Tags: Processes, Metallurgy, Heat Treatment

Metal Properties: Toughness

Toughness is a mechanical property that measures the amount of energy a material can withstand, or absorb, before fracturing. In the context of other mechanical properties, toughness for steel products represents a balance of strength and ductility.

As a material term, toughness can sometimes cause confusion: two very different materials can both be considered tough. For example, an iron anvil is tough because its strength is very high, and it resists fracture by maintaining its material integrity thanks to its strength. On the other end of the spectrum, silly putty is also a tough material, not because it’s strong but because it’s very ductile and will resist fracture until you pull it far enough apart that the two ends separate. Anvils and silly putty are very different, but they’re similar in that they are both tough, and they both absorb a good deal of energy before fracturing.

Heat Treatment: Annealing

The heat treatment known as annealing encompasses a group of processing heat treatments. Unlike thermal processes that are used to improve the strength and wear resistance of a part (such as hardening heat treatments), processing heat treatments are used to prepare a workpiece for further manufacturing processes. Chiefly, this means improving a material’s responsiveness to machining or cold-working by restoring (and even enhancing) ductility.

After an annealing process, the part can be expected to go to the machine shop for additional subtractive manufacturing, or to a mill to be cold worked. In fact, annealing makes machining and cold working easier (even possible) by relieving internal stresses, reducing hardness, increasing ductility and toughness, and softening the material to make it more machinable and workable.

Tags: Processes, Metallurgy, Heat Treatment

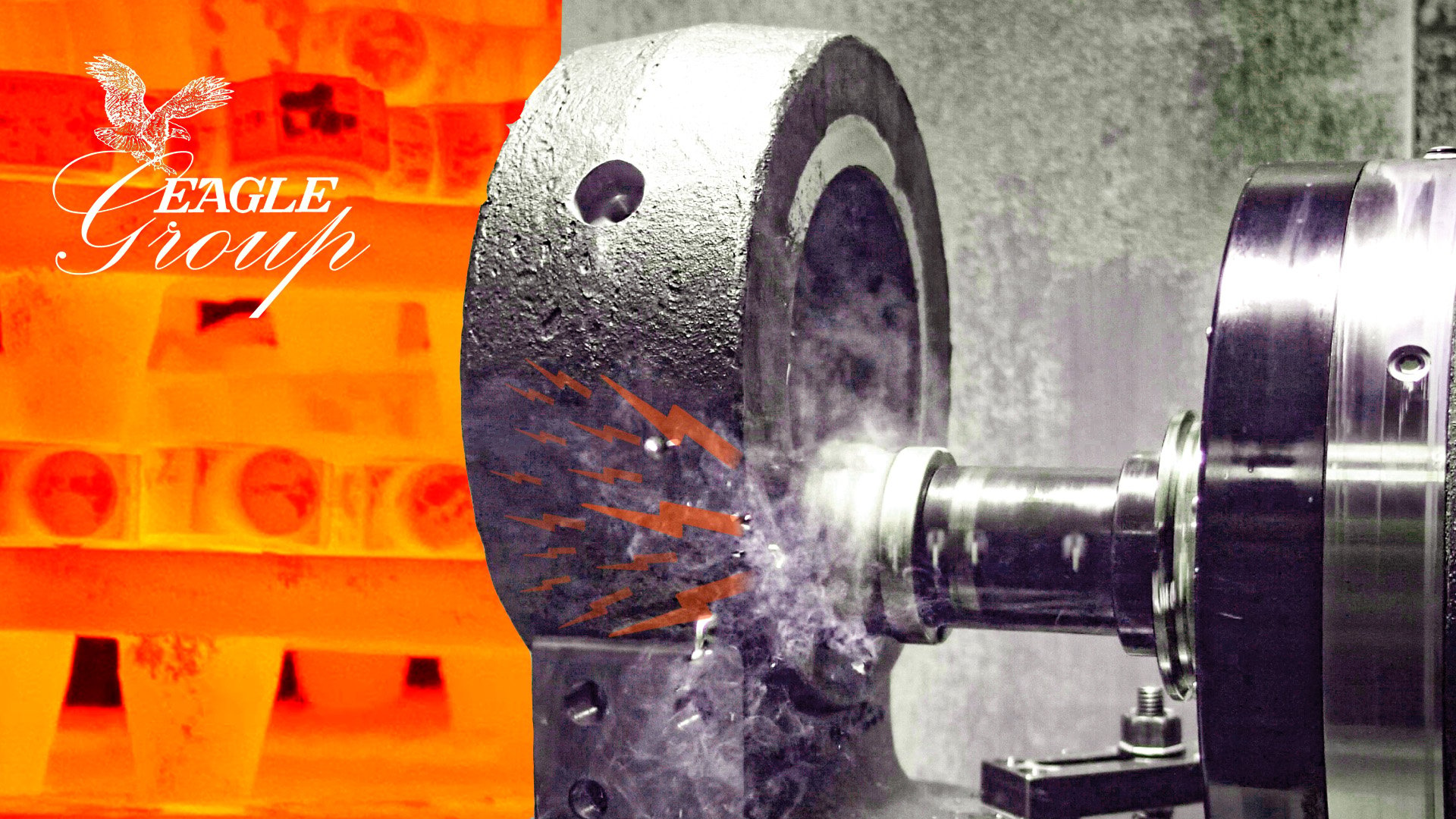

Heat Treatment: Quenching

Imagine a medieval blacksmith hammering a sword fresh out of the fire. With the weapon still red-hot, he dunks it in water. The water hisses and boils around the submerged steel as it turns color from glowing orange to grey. This iconic scene of rapidly cooling a workpiece is called quenching, or quench hardening, and is one of the oldest and most common heat treatment processes used to harden and strengthen common carbon steels. In modern metallurgy, superior corrosion resistance for most stainless steels is also an important property achieved through quenching.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Stress Relief

Internal stresses form naturally during many manufacturing processes. Machining, stamping and welding, for example, are common manufacturing methods that augment the amount of stress in a material’s fabric. And although stress build-up is a natural byproduct of these processes, too much of it leads very commonly to part distortion. Most of these stresses must therefore be removed before a part can be considered ready and safe to use. Thanks to heat treatment, these stresses can be relieved (without changing a part’s mechanical properties) through a thermal process known as stress relieving.

Tags: Processes, Metallurgy, Heat Treatment