New Article in Modern Casting Magazine: Modular Automation at Eagle Precision

Automation in investment casting is often seen as the domain of large-scale foundries, with a common perception that it requires major capital investment, significant floor space, and rigid shop-floor layouts. But what if there were a way to bring the benefits of robotic automation to foundries of any size?

Tags: Eagle Precision, Capabilities, Equipment

Improving Casting Production with In-House Robotics Expertise

In many ways Dakota Hanson (above) is a typical Young Millennial: he's an avid Tik Tok fan, spends his spare time playing Call of Duty, and has a job working with cutting-edge technology. However, unlike many members of his generation, Dakota's workplace is more than a laptop and a WIFI connection. As an Engineering Technician at Eagle Alloy (a shell molding facility in Muskegon, MI) Hanson specializes in programming robotic cells that play an integral role in the manufacturing process.

In fact, Eagle Alloy has a growing number of employees whose job descriptions include programming and operating robotic cells. Through a continuing education program led by robotics manufacturer ABB, Eagle Alloy has been able to provide its in-house team with manufacturing robotics expertise, further improving the company’s response time and resilience.

Tags: Eagle Alloy, Capabilities, Technology, Robotics, grinding, Employees

Induction Melting at Eagle Alloy

At Eagle Alloy, we recently expanded our capabilities by investing in three new Inductotherm induction melting furnaces. Since opening in 1979, we’ve always used induction for melting because of its efficiency and flexibility in comparison to other heating methods. These new furnaces allow us to increase our melting capacity both now and in the future.

It's easy to agree with Inductotherm when they say that "watching a piece of metal in a coil turn cherry red in a matter of seconds can be surprising to those unfamiliar with induction heating." The process of induction heating is as fascinating as it is useful. Here, we explore the origins of induction heating and its applications in metalcasting.

Tags: Capabilities, Melting, Induction

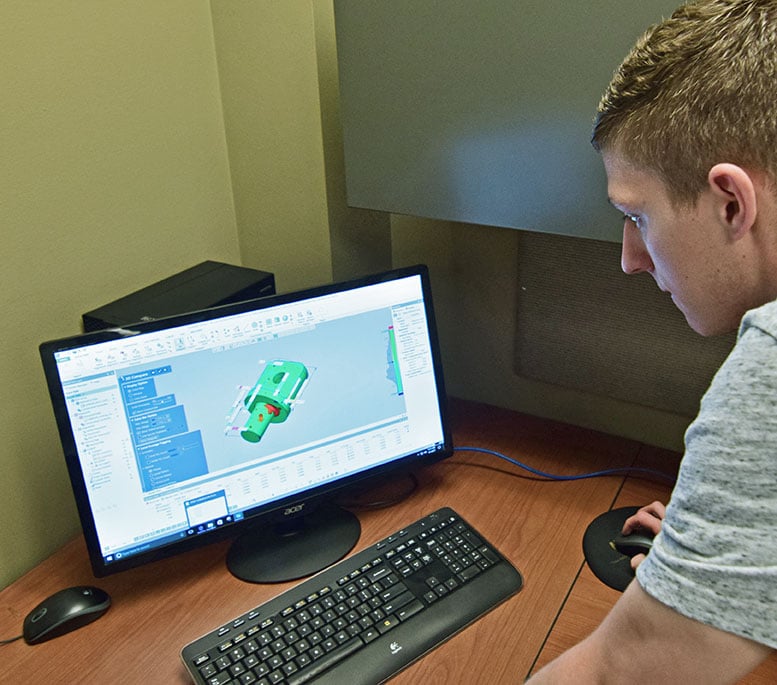

Designing Cast Products: 3D Modeling and Solidification Simulation Software

The rise of CAD/CAM software largely defines the current era of manufacturing. While blueprints and dimensional charts are still widely used as reference guides, modern manufacturers rely on software to design prototypes and simulate casting processes. One of the first steps in the cast part development process is to create a 3D model. From there, engineers can improve the part shape, simulate a variety of casting processes and materials, and troubleshoot difficult manufacturing scenarios.

When done right, CAD/CAM software enables foundries to solve all the problems of casting in the virtual world, before pouring any metal. The results are cost savings for the customer, time savings for everyone, and reduction of overall waste.

Tags: Product Design, Development, Capabilities, Inspection, Product Development, Technology, CAD/CAM

Getting Started with the Eagle Group: What You Need to Know

The Eagle Group is comprised of three companies: a shell molding foundry, an investment casting foundry and a CNC machine house. Together, we're able to manufacture a broad range of metal products from concept to completion.

If you're looking for a new supplier for your raw or machined cast products, the Eagle Group could be the perfect fit. We pride ourselves on customer satisfaction, continuous improvement and outstanding work during all phases of the production process.

Tags: Metalcasting, Manufacturing, Product Design, Development, Capabilities, Product Development