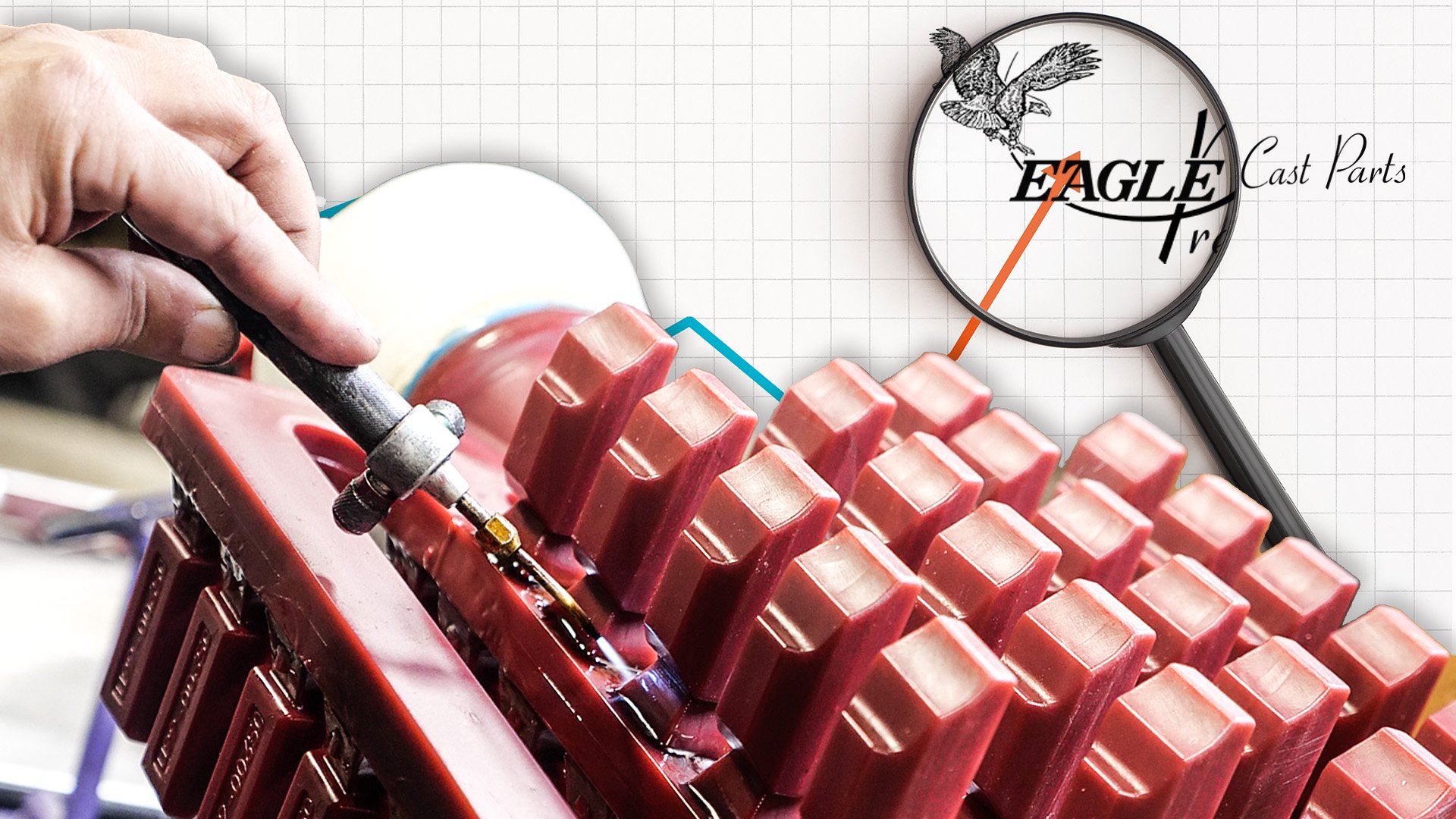

Continuous Improvement at Eagle Precision: Optimizing the Investment Casting Wax Room

This article is part of our series: Continuous Improvement at Eagle Precision

The wax room is at the heart (and start) of our investment castings. By injecting the wax room with fresh ideas, we’ve been able to greatly improve our pouring efficiency, leading to higher production yields, less downtime, reduced remelting rates, and faster delivery times.

Tags: Lean Manufacturing, Investment Casting, Eagle Precision, Continuous Improvement

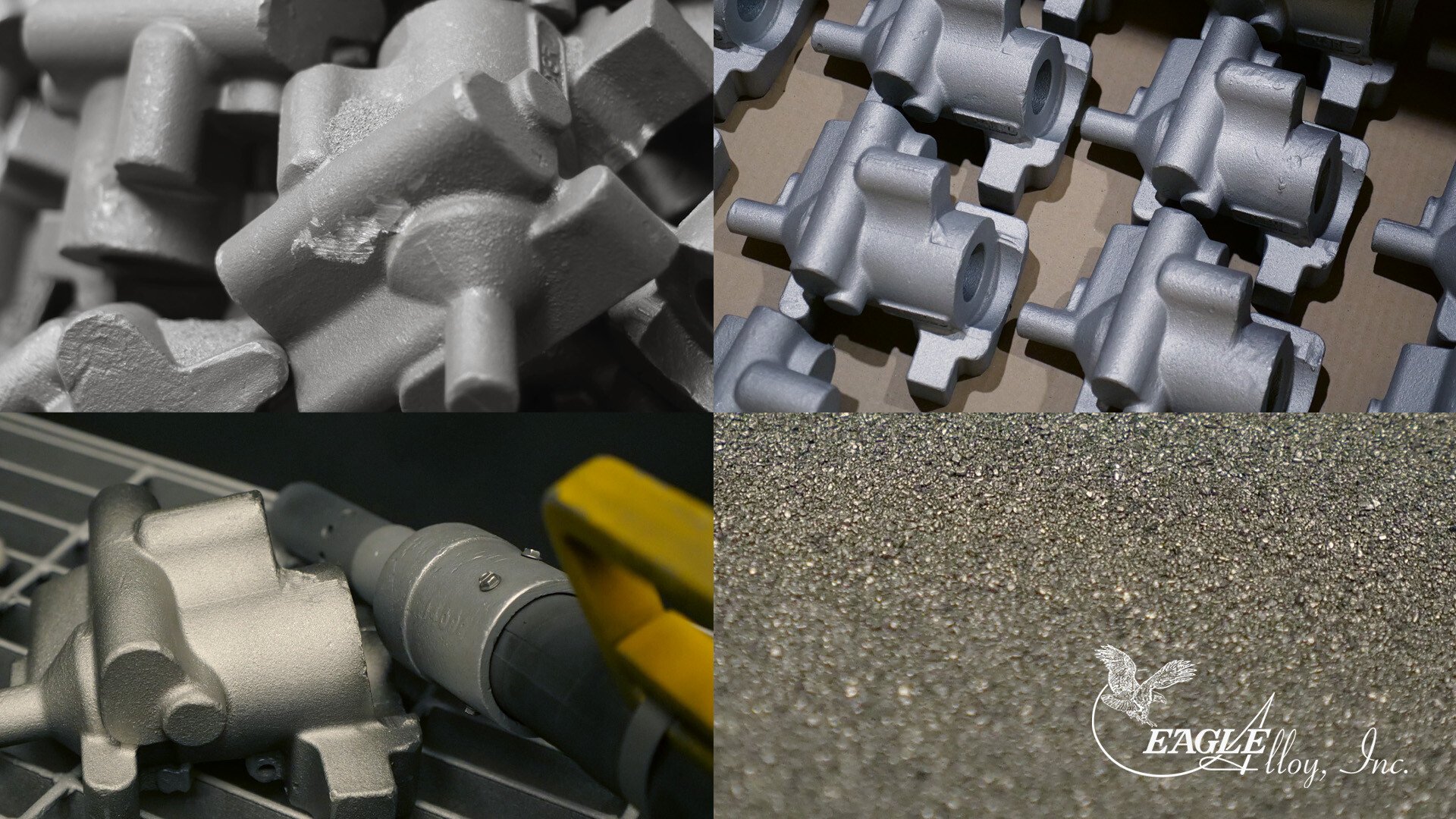

After Casting: Perfecting the Blasting Process

After a casting solidifies in the mold, the part undergoes a number of post processes to prepare it for delivery. One of the most commonly used post processes is blasting, an intensive cleaning process that removes debris and excess material from castings. At the Eagle Group, blasting plays a pivotal role in prepping casting surfaces for delivery or for further processing. Our latest investment in state-of-the-art stainless-steel grit and an optimized media blasting process is paying dividends for our customers and our employees by providing cleaner parts, less oxidation, and a safer workplace.

But getting to this point has been a years-long journey. Here's how we got here.

Tags: Lean Manufacturing, Eagle Alloy, Equipment, Continuous Improvement, Blasting

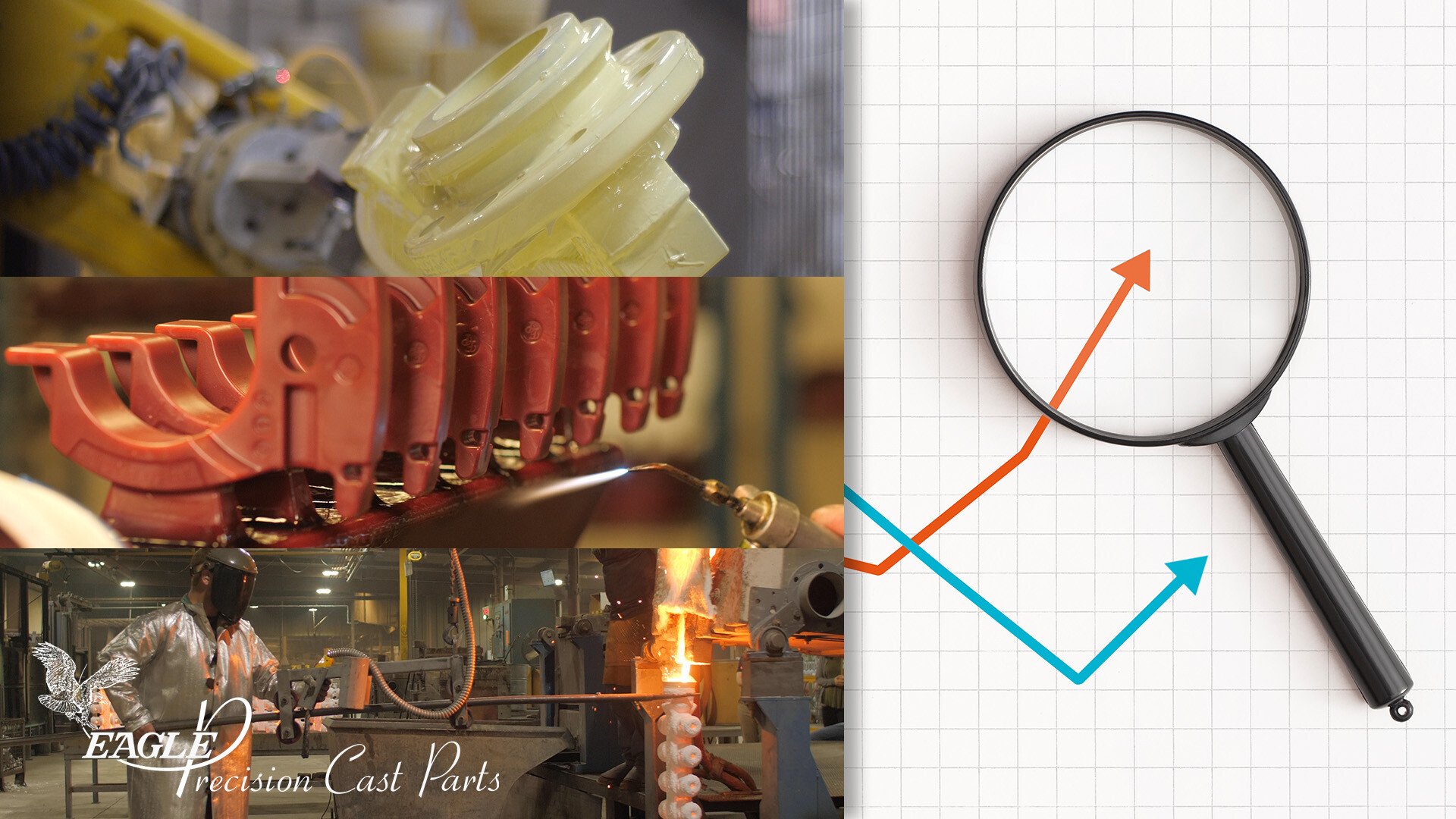

Continuous Improvement in Investment Casting

This article is part of our series: Continuous Improvement at Eagle Precision

Continuous improvement is an ongoing effort to make incremental changes in a company’s processes that improve efficiency and quality. While the concept is fairly simple, many businesses find it challenging to sustain continuous improvement over the long term.

Continuous improvement is one facet of Lean Manufacturing, which is a set of tools used to maximize output and minimize waste. The meaning of ‘minimizing waste’ in manufacturing is a far-reaching term. Some examples include:

- Unused material reclamation and recycling

- Cutting down on energy and transportation costs

- Reducing wait times

- Minimizing product defects and returns

Tags: Lean Manufacturing, Eagle Precision, Robotics, Continuous Improvement