The Benefits of Machined Part to Casting Conversion

Metalcasting is a highly versatile manufacturing process. In fact, many manufacturing professionals are not aware of just how versatile it is, and they continue to produce parts through other less efficient methods. While there is certainly a necessity for fabrication and machining in the metal manufacturing world, these processes can sometimes be replaced by casting.

Tags: Machining, Investment Casting, Productivity, Eagle Precision

New Resource for Manufacturers: CNC Machining Process Guide

The latest resource from the Eagle Group focuses on CNC machining and high-tech inspection. Our ebook CNC Machining Process Guide dives into the history, current practices and processes of CNC machining and advanced metrology. Perfect for anyone looking for a better understanding of precision machining in the 21st century, our new resource is available now as a free download.

Tags: Machining, CNC Machining, Metrology

Ebook for Manufacturers: Metalcasting & CNC Machining Process Guide

Tags: Metalcasting, Machining, CNC Machining

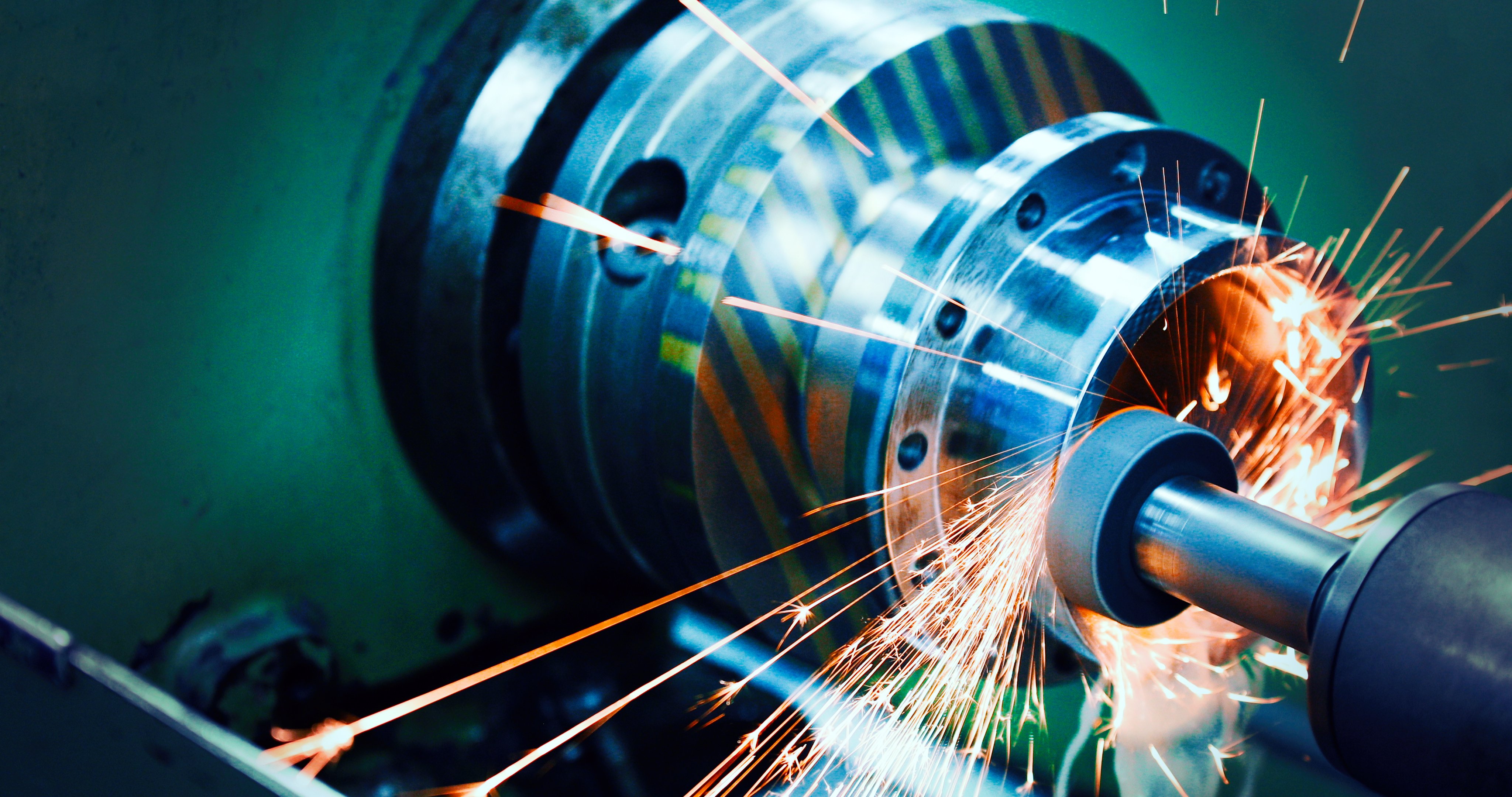

What Precision Machine Shops Do: Grinding

Grinding is a machining process using abrasive surfaces to remove material from metal workpieces. On the surface (pun intended) grinding may seem different than other machining processes, but it still works through chip formation and removal–just like sawing, milling, broaching and most other techniques. Grinding can produce surfaces conforming to rough or extremely close tolerances. Because of its versatility, grinding is used for simple gate removal in castings as well as advanced finishing processes like polishing and sharpening.

Tags: Processes, Machining, Eagle CNC, What Precision Machine Shops Do, grinding

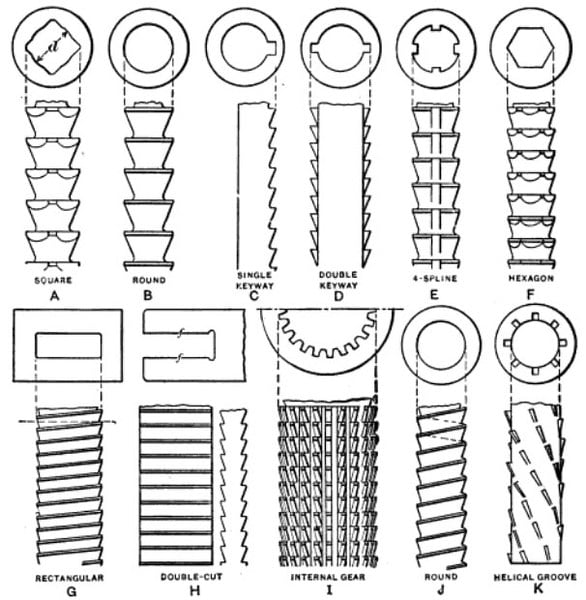

What Precision Machine Shops Do: Broaching

Broaching is a machining process using a cutting tool with teeth that increase in size from front to back. In many cases, an entire surface (or multiple surfaces) can be finished in a single pass with broaching. The technique is most often applied to finish holes, splines and flat surfaces.

Broaching is a relatively new machining process, developed in the 1850s with metal-specific applications. Originally, broaching was used to perform work on internal characteristics, like keyholes in pulleys and gears. During the 20th century, broaching was further developed for use in firearms, and subsequent developments have dramatically improved tolerances and made broaching more versatile for modern machine shops.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do, broaching

What Precision Machine Shops Do: Sawing

Sawing is one of the oldest cutting techniques in use today, and innovations have allowed the process to keep up with advances in material, tolerances and product complexity. By definition, sawing is cutting a narrow slit in a workpiece by moving a toothed or abrasive cutting tool against the surface. Sawing is often used to remove large sections of material without particular concern for tolerances, but modern CNC sawing machines can be used for finishing work as well.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

What Precision Machine Shops Do: Boring

Boring may not sound like a very exciting topic, but don't let names deceive you: boring is one of the most widely used techniques in machining, and one of the most reliable ways to finish holes.

Boring is the process of enlarging and finishing pre-existing holes. The holes might have been cast, drilled or otherwise formed to a rough state, but boring is often the best technique to provide the accuracy and repeatability expected of CNC machined parts.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

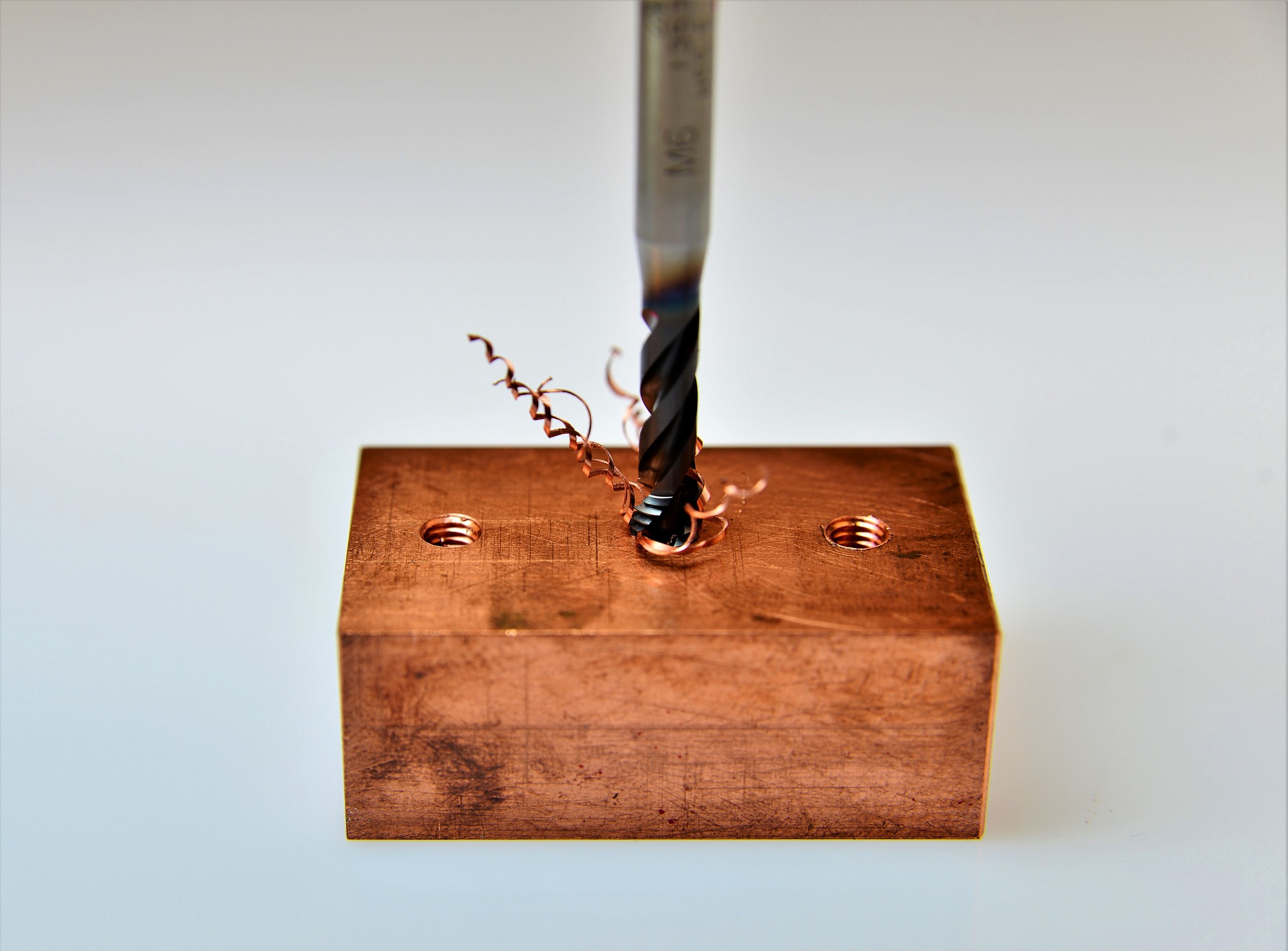

What Precision Machine Shops Do: Drilling

Drilling is one of the most common techniques used in manufacturing to create holes. In contrast to other hole-making methods like boring, reaming and tapping, drilling is most often used to create holes in unbroken surfaces. In precision CNC machining, drilling can range in scope from simple, rough hole drilling to complex, multi-feature hole drilling.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

What Precision Machine Shops Do: Milling

Milling is one of the most common processes in CNC machining, most likely because it is so versatile. Using a single tool, machine shops can create nearly limitless shapes on the surface of a workpiece. Milling can completely transform a piece of metal stock into a finished part of nearly any complexity.

The milling process in CNC machining consists of removing material with a rotating cutting tool. Unlike turning, the workpiece does not need to rotate in milling operations. In some cases, the workpiece will move linearly against a cutting tool; in other cases, the workpiece will remain stationary while the cutting tool moves.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Milling, What Precision Machine Shops Do

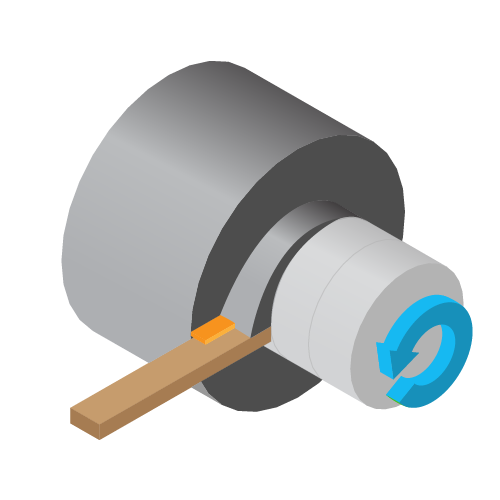

What Precision Machine Shops Do: Turning

Turning has been practiced by machinists for centuries on many different materials. Originally, turning acted on wood to create complex, cylindrical designs for use in tools, handles, furniture. Today, turning is a vital part of the metal manufacturing process, and a major technique used by precision CNC machine shops in the United States and around the globe.

Turning is the process of rotating a workpiece and bringing it into contact with a cutting tool. As the workpiece turns, the rotating motion forces the cutting tool to strip away material. The cutting tool itself can move linearly, either parallel or perpendicular to the axis of the spinning workpiece. Cuts made in turning, and the resulting shape of the workpiece, are determined by the motion and shape of the cutting tool.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Turning, Lathe, What Precision Machine Shops Do