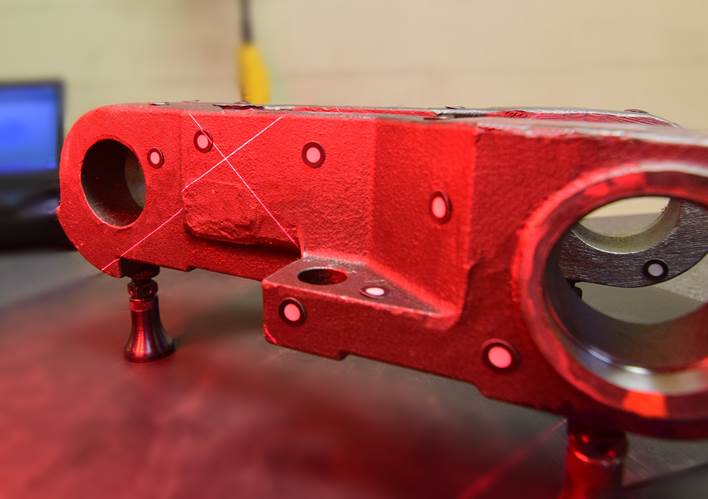

Michigan Manufacturers Honor Veterans by Reviving a Sunken Patrol Boat

Collaboration Between Casting and Machining to Re-Engineer a Lost Component of a Vietnam-Era Patrol Boat

Muskegon-based manufacturers Eagle CNC and Eagle Alloy put their capabilities to the test when they set out to replicate a key component of a Vietnam-era patrol boat as a steel casting. For the team behind the casting, this project is about more than fixing a boat; it’s about preserving history, honoring the legacy of those who served and sacrificed, and ensuring their stories continue to be told for generations to come.

Tags: Eagle Alloy, CNC Machining, Eagle CNC, 3D Scanning, Reverse Engineering, 3D Printed Molding

Beyond Quality Control: How Eagle Alloy’s Keyence WM-6000 Boosts Foundry Capabilities

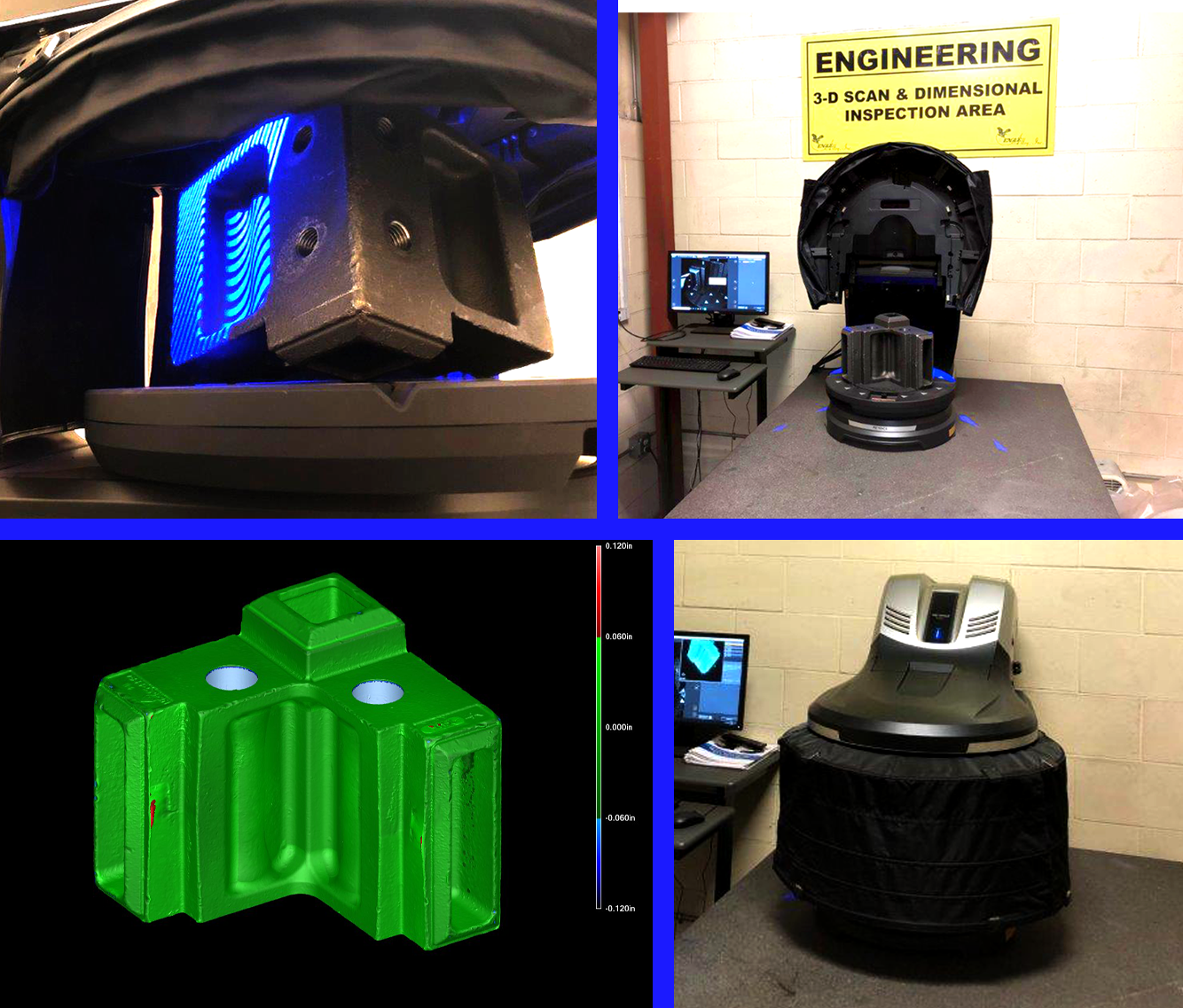

The Eagle Group realized early on the value of 3D scanning for manufacturing. Eagle CNC, Eagle Precision and Eagle Alloy all utilize 3D scanning systems that optimize our capabilities not just for inspection, but also for reverse engineering and prototyping. For us, scanning is an integral part of the casting process.

That’s why Eagle Alloy has upgraded its Keyence scanner several times to stay ahead of the curve. Our latest model, the WM-6000, helps our shell-mold foundry deliver even more precise, reliable castings for our customers.

Tags: 3D Scanning

State-of-the-Art 3D Scanning for Cast Products

The Eagle Group Blog previously wrote about our handheld laser scanner, capable of processing 1-2 million individual location points to accurately measure any surface. We recently built on that capability and purchased a Keyence VL-550 3D scanner CMM. The intuitive user interface, proprietary software and raw scanning power of the new equipment means we can process samples faster than ever before. By reducing measurement time and improving ease of use, we also open up a number of opportunities for advanced quality control.

Tags: Product Design, Development, Product Development, Measurement, 3D Scanning

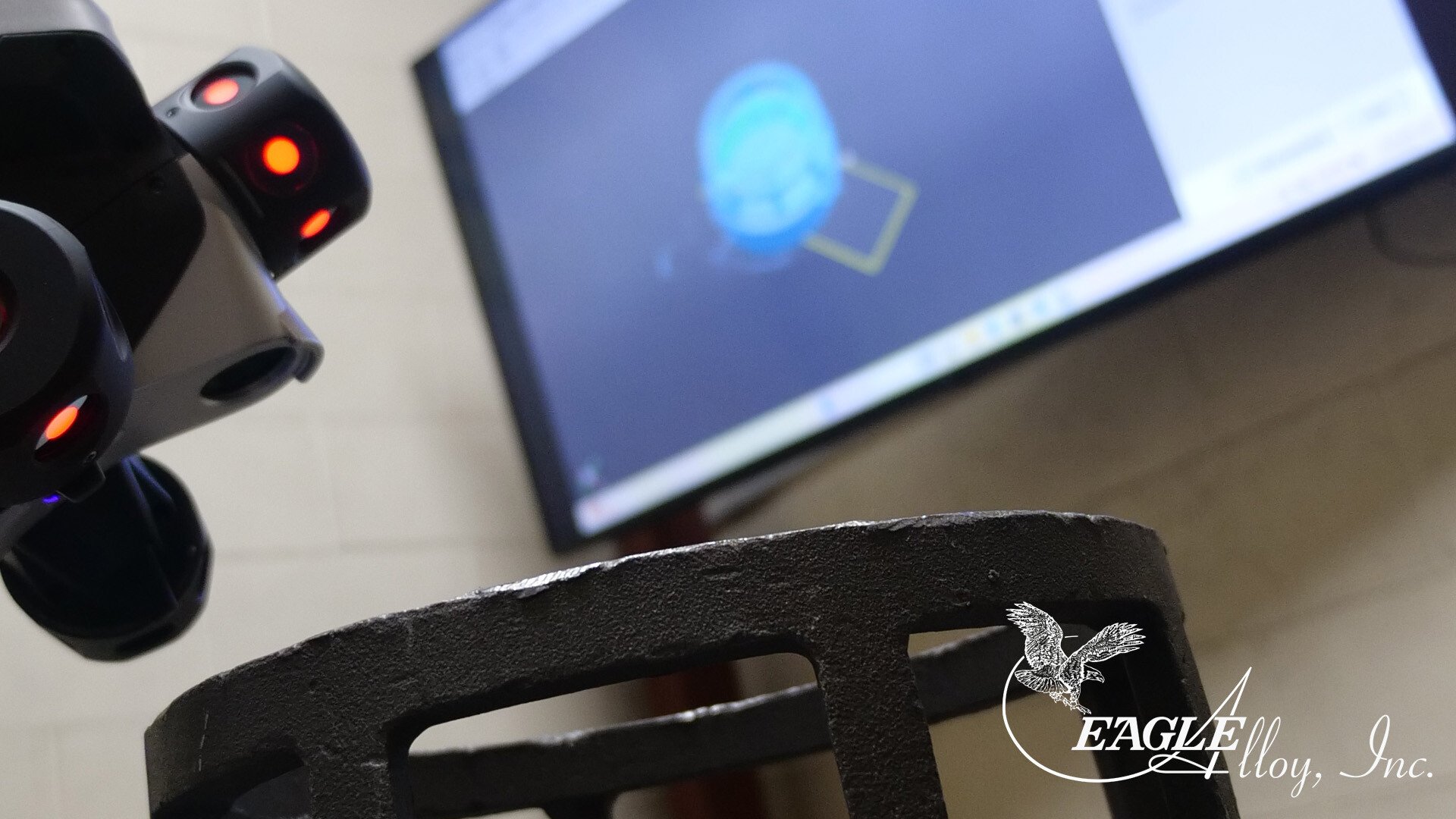

How Eagle Alloy's Handheld Laser Scanner Leads to Better Cast Products

Product development processes vary widely from foundry to foundry. The Eagle Group's Product Development blog series aims to highlight practices used by leading foundries that prioritize quality in every part they produce.

One product development practice that sets Eagle Alloy apart from other shell molding foundries is their use of a handheld laser scanner for inspection and dimensional reporting. This technology greatly improves the accuracy of dimensional reports, and makes it easier for customers to verify that new parts meet their requirements.

Tags: Metrology, Product Design, Development, Inspection, Product Development, Technology, 3D Scanning