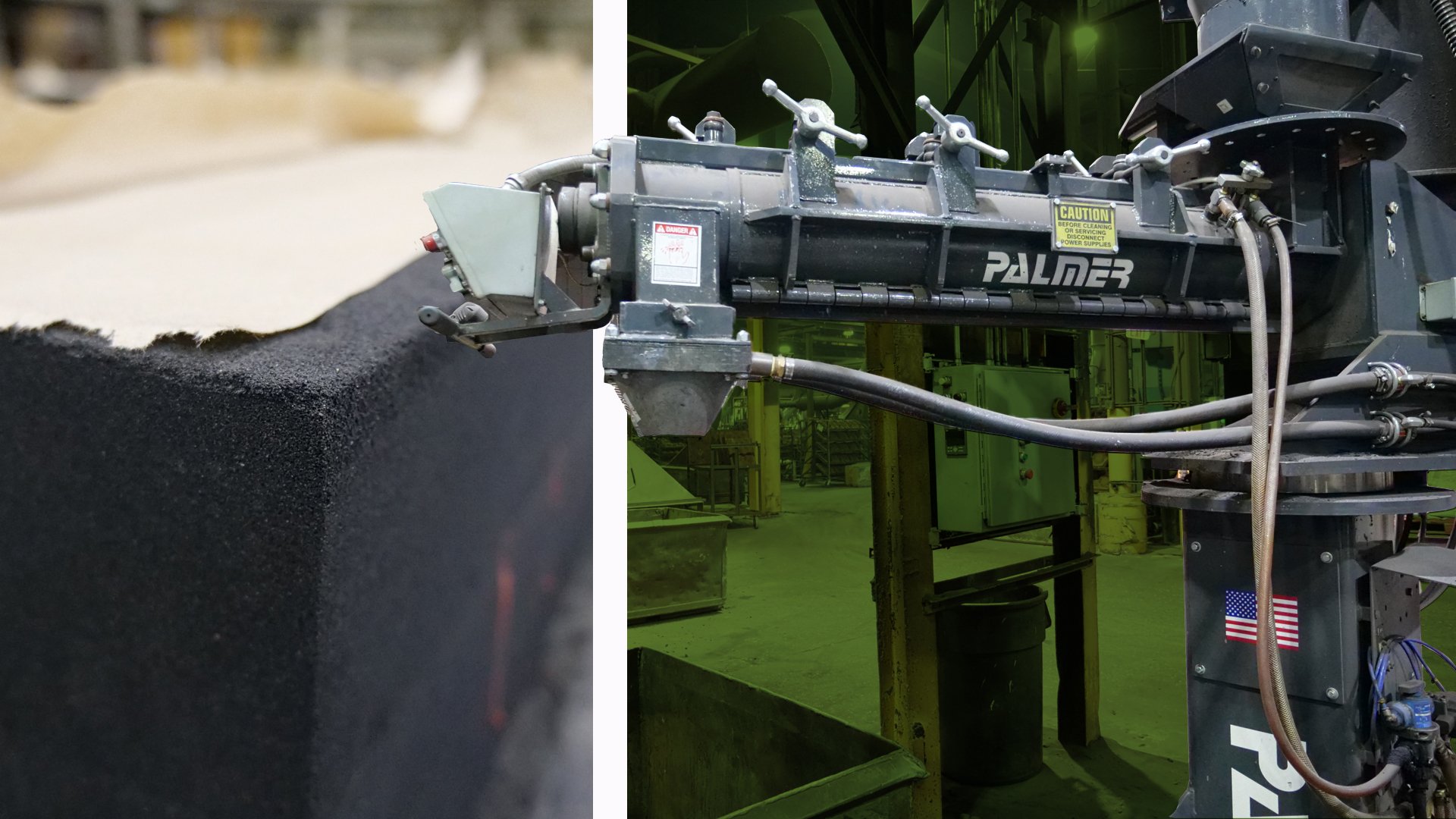

Eagle Alloy Upgrades Casting Facilities with New Airset Sand Mixer

The Eagle Group produces a wide variety of cast and machined products for many industries. One of our strengths as a company is our ability to employ different casting processes. Eagle Precision Cast Parts, for example, specializes in investment casting, and Eagle Alloy specializes in shell molding. When you tour the shop floor at Eagle Alloy, you’ll see our shell molding machines busy at work, turning out most of our order flow. But that’s not all we do: Eagle Alloy also houses a robust airset (no-bake) molding line to support our shell customers.

Tags: Eagle Alloy, Airset Casting, Facilities, Equipment

CAST IN STEEL: Student Teams Compete to Cast the Best Steel Viking Axe

This year the Steel Founders' Society of America (SFSA) introduced a national competition to engage students with steel casting and help foundries connect with the next generation of manufacturing professionals. Inspired by History Channel's Forged in Fire, the Cast in Steel competition brings teams of engineering students from around the country together to find out who can cast the best Viking axe. Testing, judging and awards took place prior to CastExpo in Atlanta, GA.

Tags: Investment Casting, Eagle Precision, Airset Casting, Event, Student Metalcasting Competition, CastExpo, Trade Associations

Getting Started with Airset Casting

Every manufacturer bringing a cast product to market must decide on the right casting process to use. Casting methods like shell molding, greensand casting, investment casting and airset casting all have their own sets of benefits and drawbacks. The right choice depends on the quantity being cast, the size of the part, and the requirements for dimensional accuracy, surface finish and material.

While it's not as widely used as shell molding or greensand casting, airset casting has plenty of advantages, and can be the perfect option for the right product.

Tags: Metalcasting, Eagle Alloy, Airset Casting