Recent Posts

Eagle CNC Technologies Welcomes Jason Clark as New VP/GM of Operations

Eagle CNC Technologies (ECT) is thrilled to announce a new addition to our management team. Jason Clark has joined Eagle CNC as Vice President and General Manager of Operations, a position newly created to support the Eagle Group’s plans for growth.

With more than 27 years of manufacturing experience, Jason has spent his career supporting West Michigan manufacturing. After spending four years in the U.S. Navy performing avionic maintenance for electronic counter measures and comm/nav/radar on EA6B aircraft, he returned to Michigan to work in manufacturing. In 2001, and with experience at two prestigious automotive companies under his belt, Jason joined Port City Group, a Muskegon manufacturer. Here he began in metalcasting as a Quality Systems Manager in Port City’s die casting division, and steadily rose in the ranks to become General Manager for Port City as well as VP of Operations for Michigan Wheel.

Tags: Press Release, Eagle CNC, Employment

CNC Machining Fixed Costs: Tooling

At the Eagle Group, we provide full-service metalcasting and CNC machining from start to finish. Part of our responsibility as a supplier is to estimate part price for each new product. One of the largest line items affecting final part price on any job is tooling. In metalcasting, tooling often comprises patterns used to create molds and cores. In CNC machining, tooling can refer to work holding fixtures, tool holders, cutting tools or tool inserts.

Tags: CNC Machining, Tooling

New Resource for Manufacturers: CNC Machining Process Guide

The latest resource from the Eagle Group focuses on CNC machining and high-tech inspection. Our ebook CNC Machining Process Guide dives into the history, current practices and processes of CNC machining and advanced metrology. Perfect for anyone looking for a better understanding of precision machining in the 21st century, our new resource is available now as a free download.

Tags: Machining, CNC Machining, Metrology

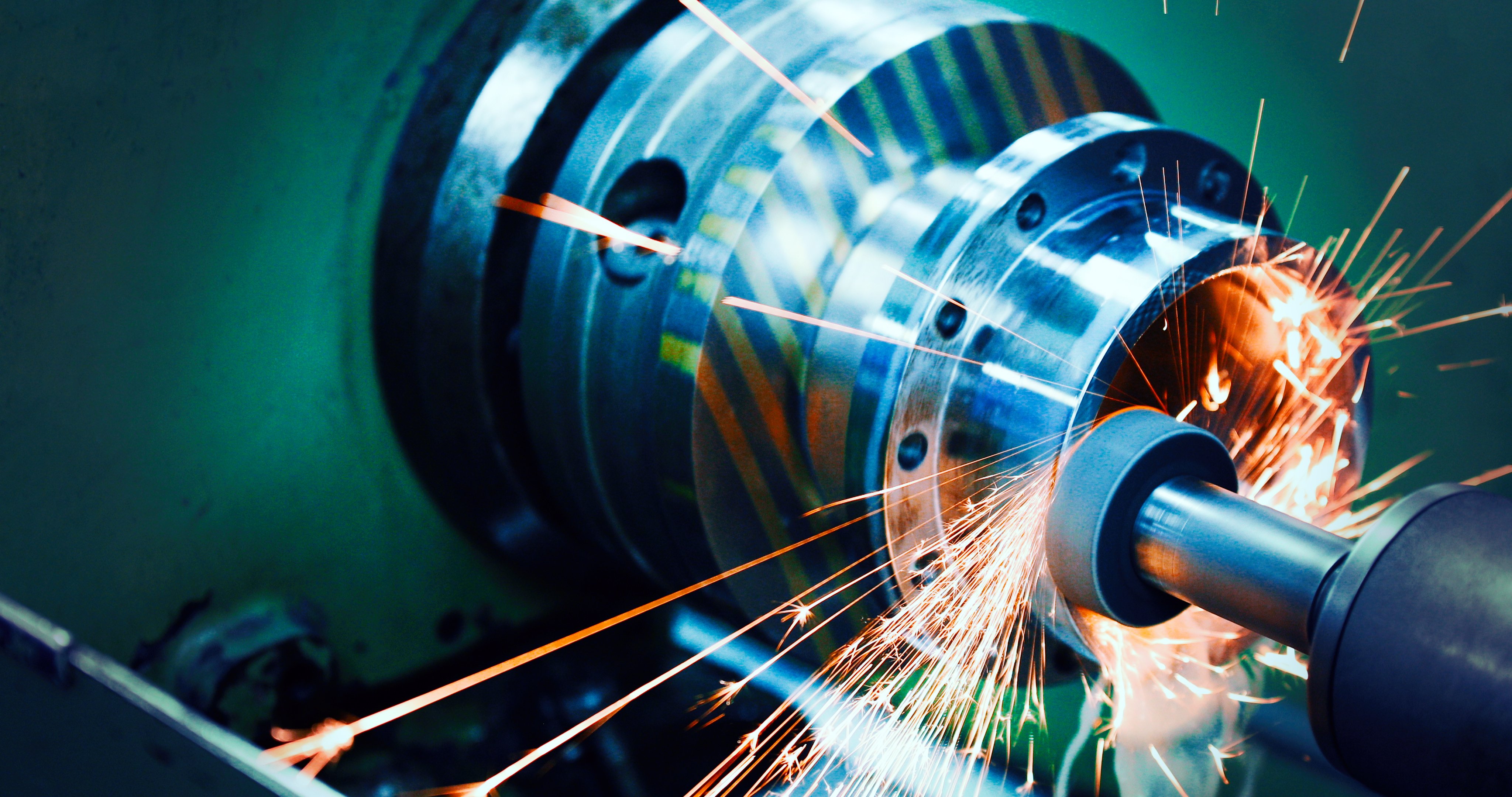

What Precision Machine Shops Do: Grinding

Grinding is a machining process using abrasive surfaces to remove material from metal workpieces. On the surface (pun intended) grinding may seem different than other machining processes, but it still works through chip formation and removal–just like sawing, milling, broaching and most other techniques. Grinding can produce surfaces conforming to rough or extremely close tolerances. Because of its versatility, grinding is used for simple gate removal in castings as well as advanced finishing processes like polishing and sharpening.

Tags: Processes, Machining, Eagle CNC, What Precision Machine Shops Do, grinding

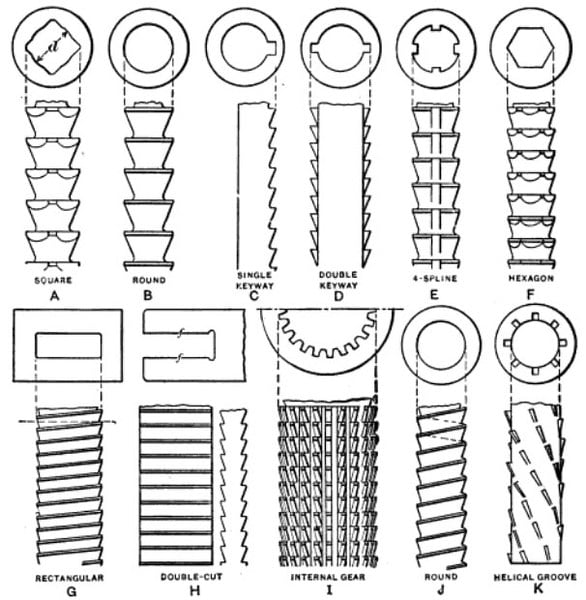

What Precision Machine Shops Do: Broaching

Broaching is a machining process using a cutting tool with teeth that increase in size from front to back. In many cases, an entire surface (or multiple surfaces) can be finished in a single pass with broaching. The technique is most often applied to finish holes, splines and flat surfaces.

Broaching is a relatively new machining process, developed in the 1850s with metal-specific applications. Originally, broaching was used to perform work on internal characteristics, like keyholes in pulleys and gears. During the 20th century, broaching was further developed for use in firearms, and subsequent developments have dramatically improved tolerances and made broaching more versatile for modern machine shops.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do, broaching

What Precision Machine Shops Do: Sawing

Sawing is one of the oldest cutting techniques in use today, and innovations have allowed the process to keep up with advances in material, tolerances and product complexity. By definition, sawing is cutting a narrow slit in a workpiece by moving a toothed or abrasive cutting tool against the surface. Sawing is often used to remove large sections of material without particular concern for tolerances, but modern CNC sawing machines can be used for finishing work as well.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

What Precision Machine Shops Do: Boring

Boring may not sound like a very exciting topic, but don't let names deceive you: boring is one of the most widely used techniques in machining, and one of the most reliable ways to finish holes.

Boring is the process of enlarging and finishing pre-existing holes. The holes might have been cast, drilled or otherwise formed to a rough state, but boring is often the best technique to provide the accuracy and repeatability expected of CNC machined parts.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

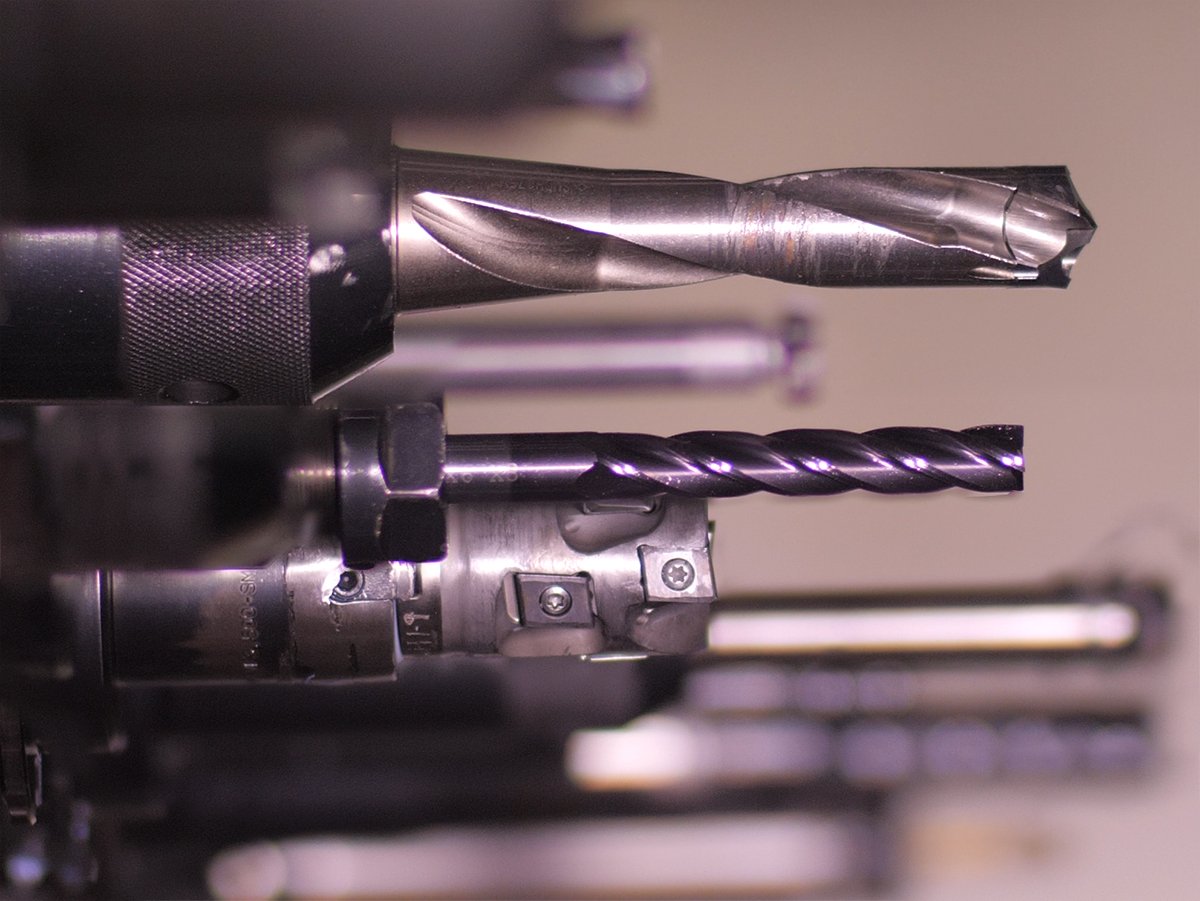

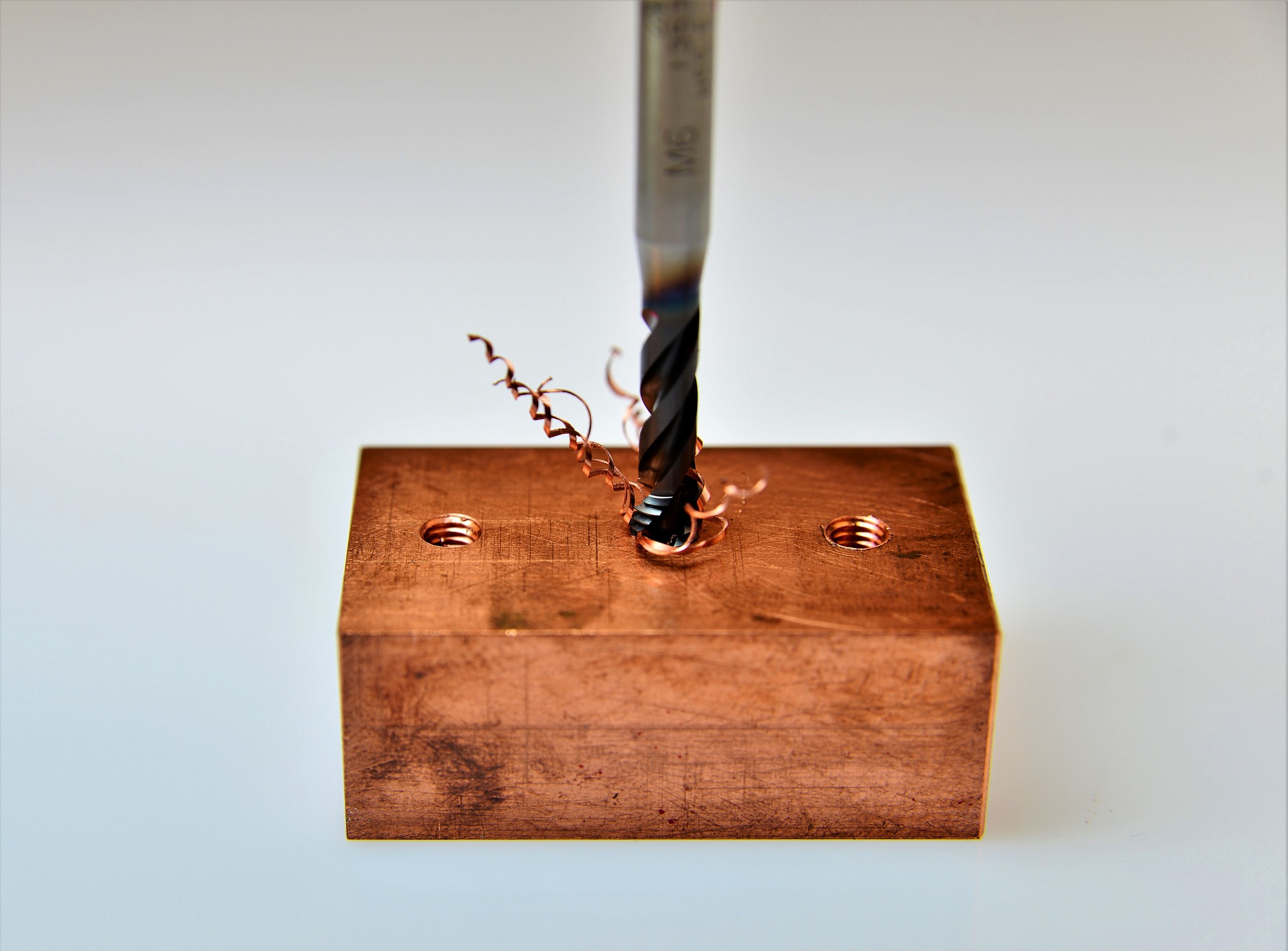

What Precision Machine Shops Do: Drilling

Drilling is one of the most common techniques used in manufacturing to create holes. In contrast to other hole-making methods like boring, reaming and tapping, drilling is most often used to create holes in unbroken surfaces. In precision CNC machining, drilling can range in scope from simple, rough hole drilling to complex, multi-feature hole drilling.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

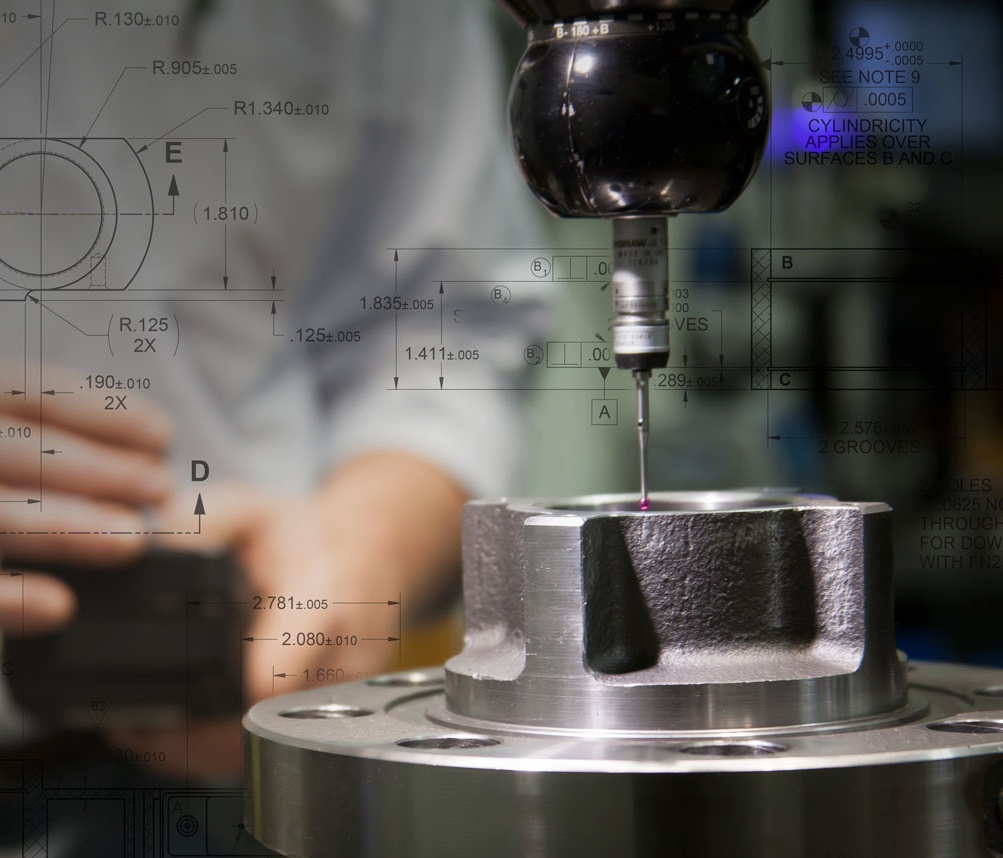

Designing Cast Products: High-Tech Inspection for High-Quality Parts

During the Eagle Group's product design process, sample runs of new cast products are subject to some of the most rigorous inspection processes available. The inspection methods we use prove to our customers that their parts will conform to specified tolerances and be free of defects. From magnetic particle inspection to laser scanning, we make sure that every new product passes a gamut of tests before it ships to the customer.

The Eagle Group regularly makes use of robust inspection technology to discover and diagnose any flaws or defects present in metal parts. In some cases, we use these methods to reverse engineer an existing part brought to us with defects. In other cases, we've pinpointed flaws in the initial design that lead to downstream manufacturing challenges.

Tags: Metrology, Inspection, Product Development

What Precision Machine Shops Do: Milling

Milling is one of the most common processes in CNC machining, most likely because it is so versatile. Using a single tool, machine shops can create nearly limitless shapes on the surface of a workpiece. Milling can completely transform a piece of metal stock into a finished part of nearly any complexity.

The milling process in CNC machining consists of removing material with a rotating cutting tool. Unlike turning, the workpiece does not need to rotate in milling operations. In some cases, the workpiece will move linearly against a cutting tool; in other cases, the workpiece will remain stationary while the cutting tool moves.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Milling, What Precision Machine Shops Do