Robotics in Investment Casting

Our investment casting foundry, Eagle Precision, makes use of robotics in two steps of the casting process. We started with a robotic dipping cell and expanded into two, followed by a third robotic cell that specializes in after-cast grinding. While robotic cells like these do require a large up-front investment, we’re already seeing company-wide benefits resulting from our use of robotics in investment casting.

Robots are becoming more and more common throughout the manufacturing industry, and investment casting is no exception. According to John Scott, VP of Sales at Buntrock Industries, the investment casting industry is seeing increased demand for robotics for three reasons: “lack of workforce availability, desire for increased process control and productivity, and improved health and safety.”

Tags: Investment Casting, Eagle Precision, Robotics, grinding

Improving Casting Production with In-House Robotics Expertise

In many ways Dakota Hanson (above) is a typical Young Millennial: he's an avid Tik Tok fan, spends his spare time playing Call of Duty, and has a job working with cutting-edge technology. However, unlike many members of his generation, Dakota's workplace is more than a laptop and a WIFI connection. As an Engineering Technician at Eagle Alloy (a shell molding facility in Muskegon, MI) Hanson specializes in programming robotic cells that play an integral role in the manufacturing process.

In fact, Eagle Alloy has a growing number of employees whose job descriptions include programming and operating robotic cells. Through a continuing education program led by robotics manufacturer ABB, Eagle Alloy has been able to provide its in-house team with manufacturing robotics expertise, further improving the company’s response time and resilience.

Tags: Eagle Alloy, Capabilities, Technology, Robotics, grinding, Employees

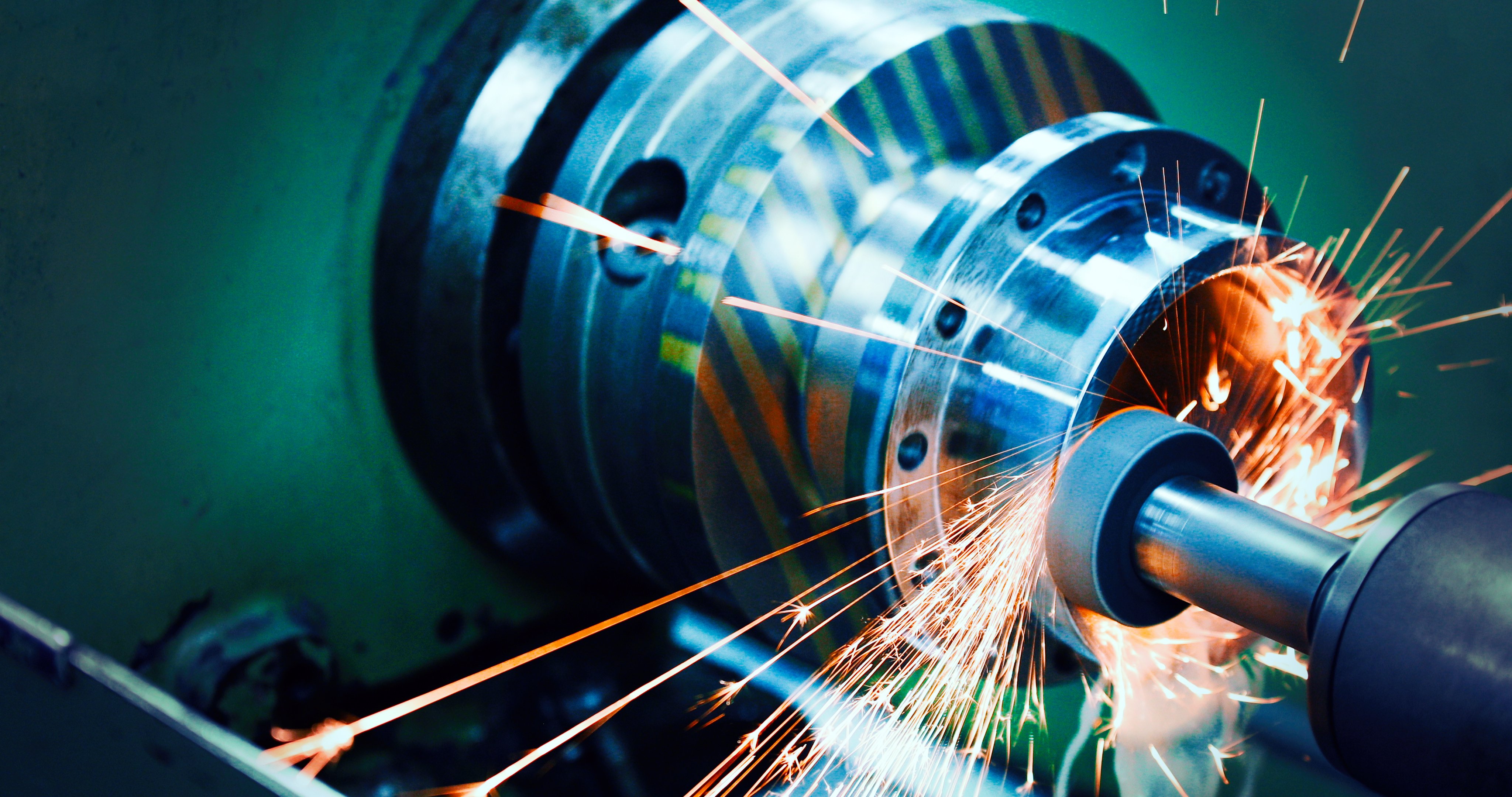

What Precision Machine Shops Do: Grinding

Grinding is a machining process using abrasive surfaces to remove material from metal workpieces. On the surface (pun intended) grinding may seem different than other machining processes, but it still works through chip formation and removal–just like sawing, milling, broaching and most other techniques. Grinding can produce surfaces conforming to rough or extremely close tolerances. Because of its versatility, grinding is used for simple gate removal in castings as well as advanced finishing processes like polishing and sharpening.

Tags: Processes, Machining, Eagle CNC, What Precision Machine Shops Do, grinding