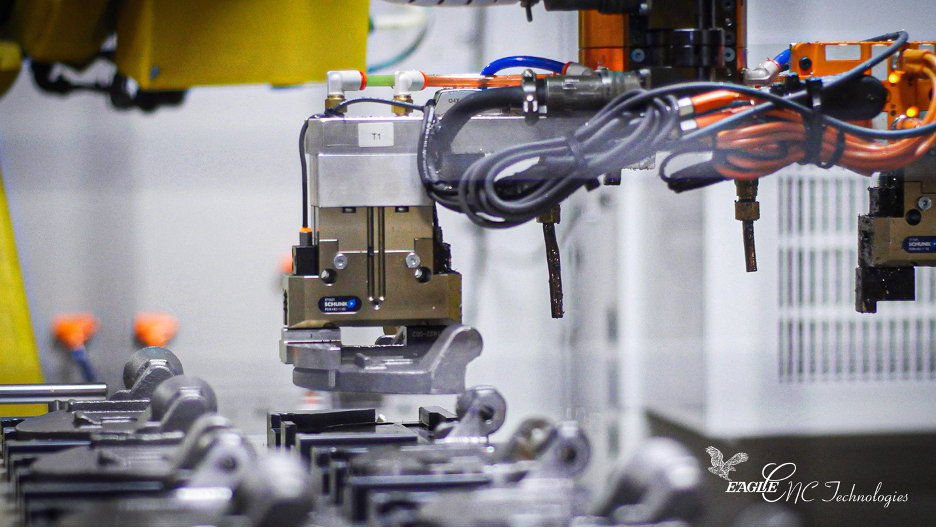

Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

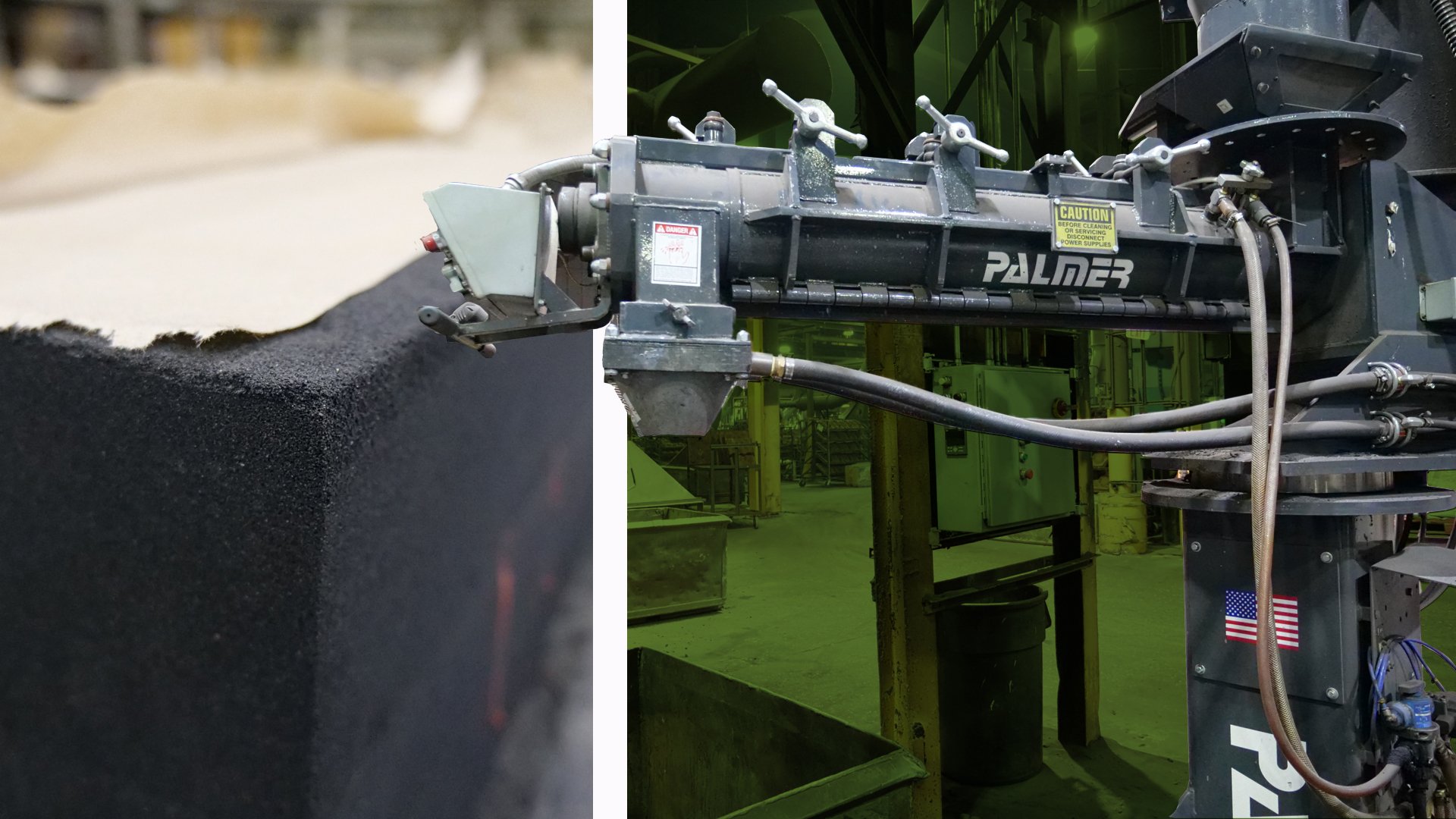

Eagle Alloy Upgrades Casting Facilities with New Airset Sand Mixer

The Eagle Group produces a wide variety of cast and machined products for many industries. One of our strengths as a company is our ability to employ different casting processes. Eagle Precision Cast Parts, for example, specializes in investment casting, and Eagle Alloy specializes in shell molding. When you tour the shop floor at Eagle Alloy, you’ll see our shell molding machines busy at work, turning out most of our order flow. But that’s not all we do: Eagle Alloy also houses a robust airset (no-bake) molding line to support our shell customers.

Tags: Eagle Alloy, Airset Casting, Facilities, Equipment

How a New Drum Blast Eliminated a Production Bottleneck

Eagle Alloy takes pride in our reputation as a world-class metalcasting facility, and we make sure every batch of castings is ready for the customer before it leaves our facility. In most cases, the final step before packing and shipping is blasting. The blasting process removes burrs, flash and other excess metal from cast parts and improves their overall surface.

Tags: Facilities, Equipment

Revamped Facilities Reflect Our Mission

Eagle Alloy's revamped facilities include a brand new cafeteria that facilitates social distancing, locker rooms with showers, and a new and improved health clinic. Completed in summer of 2020, these improvements make Eagle Alloy an even better place to work, and an even more reliable partner in the metal casting industry.

Tags: Eagle Alloy, Facilities, Human Resources