Manufacturing Internships Are a Win-Win

How Eagle CNC’s internship program benefits students, the company and the industry as a whole

A version of this article was originally published in the research journal Modern Casting in its December 2024 issue.

In the hands-on world of manufacturing, textbooks alone can't provide the full picture—real-world experience is essential for developing expertise and encouraging innovation. For both students and manufacturing companies hoping to secure talented employees in the future, internships bridge the gap between classroom theory and hands-on application, pushing limits and enabling creative problem-solving. By integrating internships into their operations, manufacturing companies foster a continuous cycle of learning, adaptation and improvement that drives innovation forward in the industry. Eagle CNC is committed to shaping the next generation of manufacturing professionals by providing practical experience and fostering essential, real-world skills through its internship program.

Tags: CNC Machining, Eagle CNC, Employment, Students, Internships

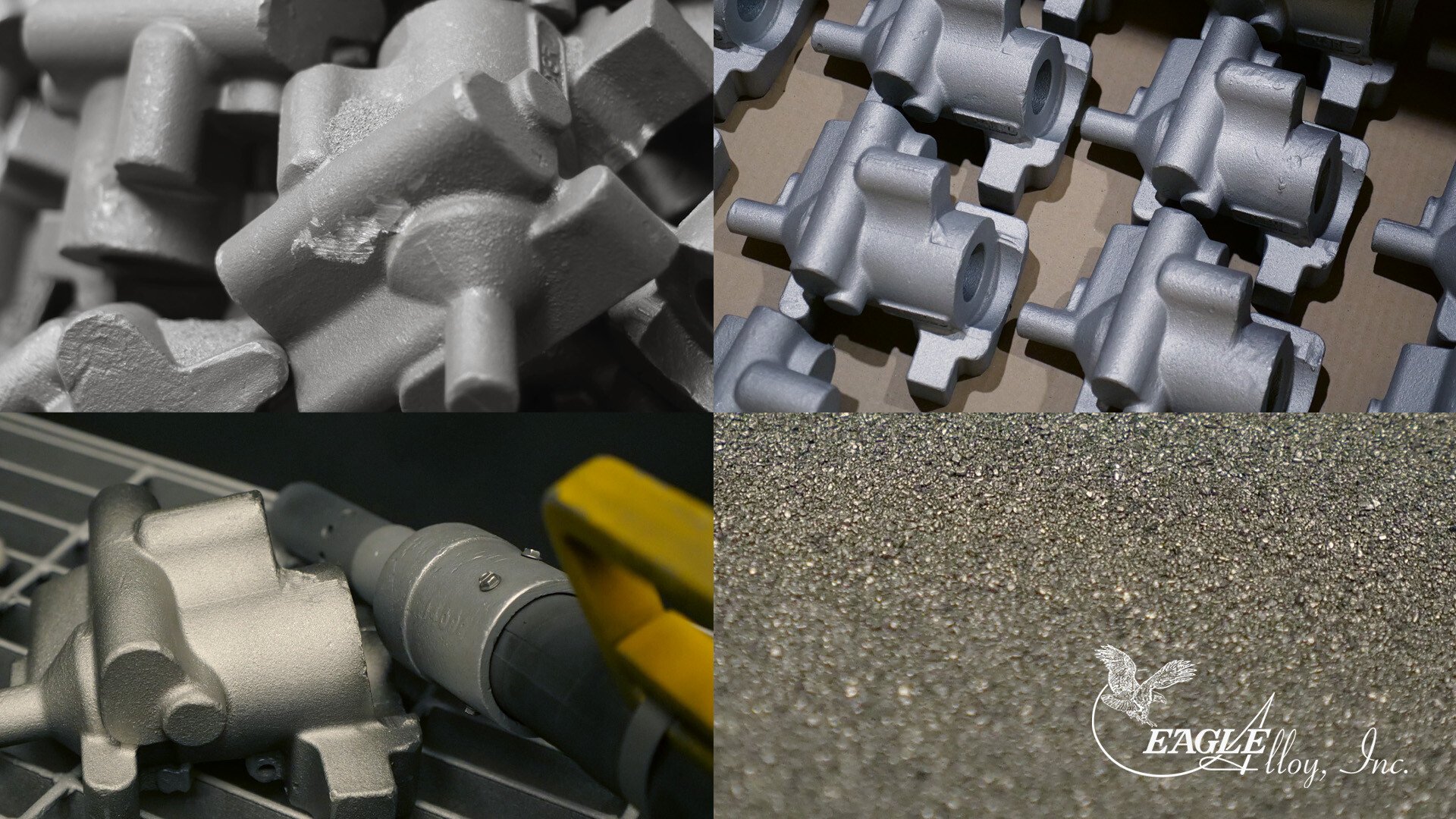

After Casting: Perfecting the Blasting Process

After a casting solidifies in the mold, the part undergoes a number of post processes to prepare it for delivery. One of the most commonly used post processes is blasting, an intensive cleaning process that removes debris and excess material from castings. At the Eagle Group, blasting plays a pivotal role in prepping casting surfaces for delivery or for further processing. Our latest investment in state-of-the-art stainless-steel grit and an optimized media blasting process is paying dividends for our customers and our employees by providing cleaner parts, less oxidation, and a safer workplace.

But getting to this point has been a years-long journey. Here's how we got here.

Tags: Lean Manufacturing, Eagle Alloy, Equipment, Continuous Improvement, Blasting

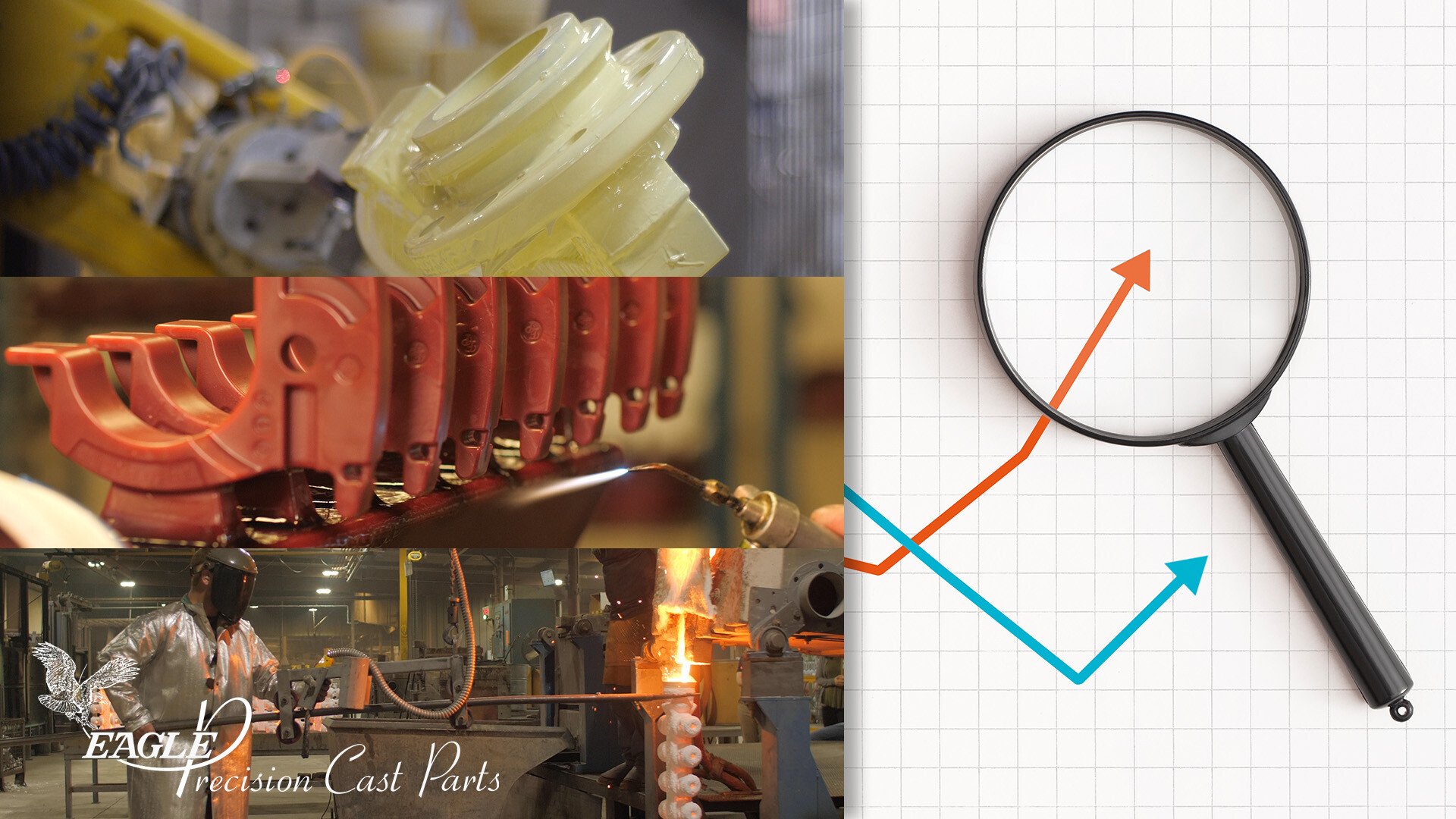

Continuous Improvement in Investment Casting

This article is part of our series: Continuous Improvement at Eagle Precision

Continuous improvement is an ongoing effort to make incremental changes in a company’s processes that improve efficiency and quality. While the concept is fairly simple, many businesses find it challenging to sustain continuous improvement over the long term.

Continuous improvement is one facet of Lean Manufacturing, which is a set of tools used to maximize output and minimize waste. The meaning of ‘minimizing waste’ in manufacturing is a far-reaching term. Some examples include:

- Unused material reclamation and recycling

- Cutting down on energy and transportation costs

- Reducing wait times

- Minimizing product defects and returns

Tags: Lean Manufacturing, Eagle Precision, Robotics, Continuous Improvement

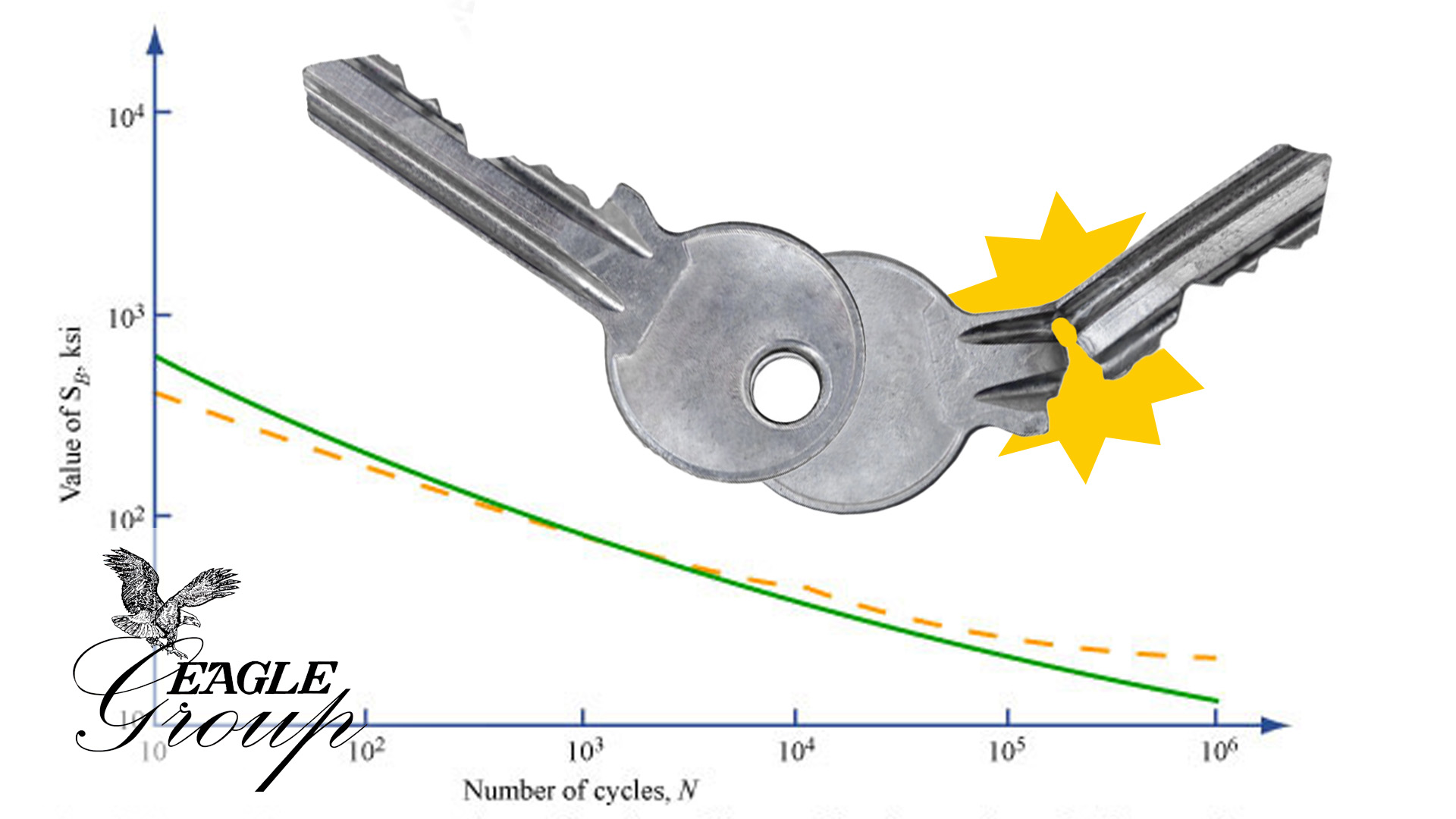

Metal Properties: Fatigue Resistance

Metal fatigue is the cracking and eventual failure of a metal workpiece under the stress of perpetual loading, a type of continual loading known in the industry as cyclic loading. Fatigue resistance in metal parts is the other side of the coin: it represents a part’s ability to avoid cracking and failure under cyclic loading. Not surprisingly, scientists and manufacturers alike have honed the processes necessary to produce components that resist failure from fatigue as efficiently as possible. Manufacturing parts with the aim of resisting failure from perpetual loading is vital for a part’s longevity in service, and for ensuring that our customers are receiving parts that meet a minimum of expected performance life.

Eagle CNC on the Rise

Just a year since being fully acquired by Eagle Alloy, the Eagle CNC team is showing their resilience and ability to thrive in their new environment

It’s been a year since Eagle Alloy fully acquired Eagle CNC, and a lot has changed. The companies are growing closer together in terms of shared systems and shared goals, and both are benefitting immensely. From improved efficiency on the shop floor to more streamlined scheduling, the partnership has opened up a world of opportunities for shared growth as a holistic, concept-to-completion manufacturing team.

Tags: CNC Machining, Eagle CNC

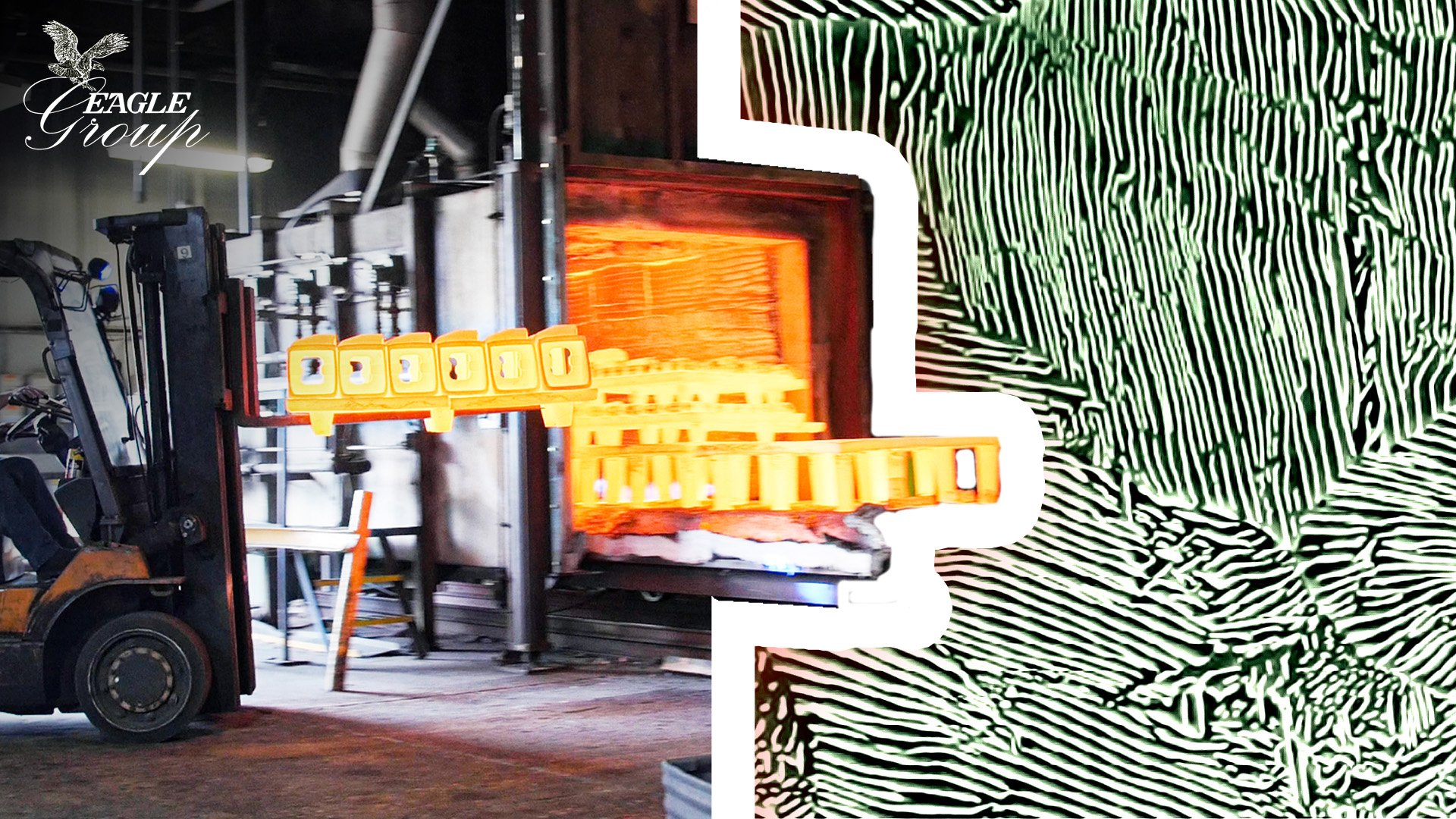

Heat Treatment: Tempering

The word ‘tempering’ generally means acting as a counterbalancing force, moving an object (or a situation) away from the extremes, toward a more balanced state. The same principle applies to heat treatment: when we temper a metal part, we are adjusting the proportion of one mechanical property against another. Specifically, we are increasing ductility while simultaneously decreasing strength and hardness.

Tempering is most often performed after a metal piece has been seriously stressed through hardening or after normalizing. When a material is hardened (especially quench hardened, the most common method of hardening), it is in an unbalanced state. In metallurgical terms, we say the metal is unstable: its molecules would like to rearrange into a more stable structure, but the quench hardening process freezes them before they get the chance. Likewise, the process of normalizing takes the steel molecules through a phase transformation, leaving stresses in its wake. (For a longer discussion of phase transformations, check out our Introduction to Heat Treatment for Cast Parts.)

Tags: Processes, Metallurgy, Heat Treatment

Bill Seyferth and Eagle CNC: A Career of Innovation in Michigan’s Manufacturing Industry

Bill Seyferth is the founder of Westech Corp., which now operates as Eagle CNC. In recent years, this state of the art machine shop has worked alongside Eagle Alloy and Eagle Precision as part of Muskegon’s Eagle Group, a manufacturing team providing casting-to-completion services for a variety of customers. As Bill retires from the company he founded, it is one of West Michigan’s largest machining facilities and carries out precision manufacturing work for Fortune 500 companies like John Deere and Caterpillar, along with a host of influential customers across a range of industries.

Tags: Eagle CNC

Metal Properties: Toughness

Toughness is a mechanical property that measures the amount of energy a material can withstand, or absorb, before fracturing. In the context of other mechanical properties, toughness for steel products represents a balance of strength and ductility.

As a material term, toughness can sometimes cause confusion: two very different materials can both be considered tough. For example, an iron anvil is tough because its strength is very high, and it resists fracture by maintaining its material integrity thanks to its strength. On the other end of the spectrum, silly putty is also a tough material, not because it’s strong but because it’s very ductile and will resist fracture until you pull it far enough apart that the two ends separate. Anvils and silly putty are very different, but they’re similar in that they are both tough, and they both absorb a good deal of energy before fracturing.

Heat Treatment: Annealing

The heat treatment known as annealing encompasses a group of processing heat treatments. Unlike thermal processes that are used to improve the strength and wear resistance of a part (such as hardening heat treatments), processing heat treatments are used to prepare a workpiece for further manufacturing processes. Chiefly, this means improving a material’s responsiveness to machining or cold-working by restoring (and even enhancing) ductility.

After an annealing process, the part can be expected to go to the machine shop for additional subtractive manufacturing, or to a mill to be cold worked. In fact, annealing makes machining and cold working easier (even possible) by relieving internal stresses, reducing hardness, increasing ductility and toughness, and softening the material to make it more machinable and workable.

Tags: Processes, Metallurgy, Heat Treatment

Heat Treatment: Quenching

Imagine a medieval blacksmith hammering a sword fresh out of the fire. With the weapon still red-hot, he dunks it in water. The water hisses and boils around the submerged steel as it turns color from glowing orange to grey. This iconic scene of rapidly cooling a workpiece is called quenching, or quench hardening, and is one of the oldest and most common heat treatment processes used to harden and strengthen common carbon steels. In modern metallurgy, superior corrosion resistance for most stainless steels is also an important property achieved through quenching.

Tags: Processes, Metallurgy, Heat Treatment