Dave Fazakerley

Recent Posts

Bill Seyferth and Eagle CNC: A Career of Innovation in Michigan’s Manufacturing Industry

Bill Seyferth is the founder of Westech Corp., which now operates as Eagle CNC. In recent years, this state of the art machine shop has worked alongside Eagle Alloy and Eagle Precision as part of Muskegon’s Eagle Group, a manufacturing team providing casting-to-completion services for a variety of customers. As Bill retires from the company he founded, it is one of West Michigan’s largest machining facilities and carries out precision manufacturing work for Fortune 500 companies like John Deere and Caterpillar, along with a host of influential customers across a range of industries.

Tags: Eagle CNC

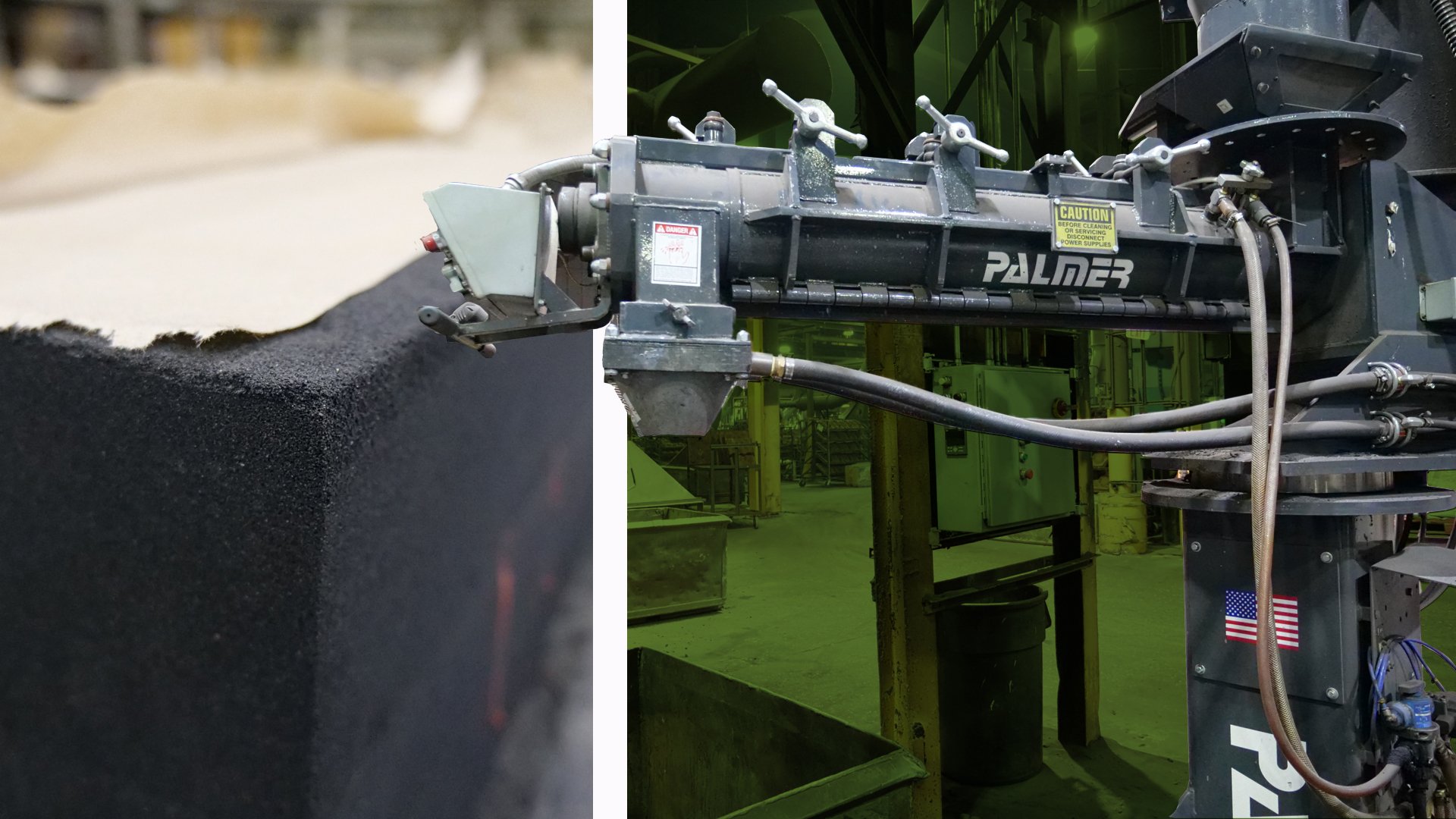

Eagle Alloy Upgrades Casting Facilities with New Airset Sand Mixer

The Eagle Group produces a wide variety of cast and machined products for many industries. One of our strengths as a company is our ability to employ different casting processes. Eagle Precision Cast Parts, for example, specializes in investment casting, and Eagle Alloy specializes in shell molding. When you tour the shop floor at Eagle Alloy, you’ll see our shell molding machines busy at work, turning out most of our order flow. But that’s not all we do: Eagle Alloy also houses a robust airset (no-bake) molding line to support our shell customers.

Tags: Eagle Alloy, Airset Casting, Facilities, Equipment

Induction Melting at Eagle Alloy

At Eagle Alloy, we recently expanded our capabilities by investing in three new Inductotherm induction melting furnaces. Since opening in 1979, we’ve always used induction for melting because of its efficiency and flexibility in comparison to other heating methods. These new furnaces allow us to increase our melting capacity both now and in the future.

It's easy to agree with Inductotherm when they say that "watching a piece of metal in a coil turn cherry red in a matter of seconds can be surprising to those unfamiliar with induction heating." The process of induction heating is as fascinating as it is useful. Here, we explore the origins of induction heating and its applications in metalcasting.

Tags: Capabilities, Melting, Induction