ESOP at Eagle Alloy: Sharing Company Ownership

ESOPs are growing in popularity among businesses around the United States. They allow company owners to transfer ownership to employees by distributing stock, creating excellent retirement benefits and promoting stability and longevity for the company. Both Eagle Alloy and Eagle Precision have ESOPs in place.

Tags: Eagle Alloy, ESOP

Eagle Alloy Turns 40

Eagle Alloy celebrated 40 years of business last weekend with a large 40th anniversary party. Founded in 1979 to meet the needs of customers looking for a short-run steel foundry and stainless steel foundry, Eagle Alloy has grown into a successful casting facility that aggressively competes globally. After four decades, we have a lot to celebrate.

Tags: Eagle Alloy, Event, Anniversary

The Rise of Robotics in Metalcasting and Machining

The use of robotics in manufacturing, including metalcasting and machining, has grown steadily since the 1970s. Industrial automation increasingly relies on robotics as a way to improve efficiency and replace monotonous, repetitive human tasks.

Robots are used for a wide variety of tasks in manufacturing, from transportation to assembly. In metalcasting and machining, robots can be used to complete nearly any programmable task, from dipping and pouring to grinding and milling.

Tags: Eagle Alloy, Eagle Precision, Robotics

Eagle Alloy, Inc. Recognized as a John Deere “Partner-Level Supplier”

Eagle Alloy, Inc. has earned recognition as a Partner-level supplier for 2018 in the John Deere Achieving Excellence Program. The Partner-level status is Deere & Company’s highest supplier rating.

Eagle Alloy was selected for the honor in recognition of our dedication to providing products and services of outstanding quality as well as our commitment to continuous improvement.

Tags: Awards, Eagle Alloy, Recognition

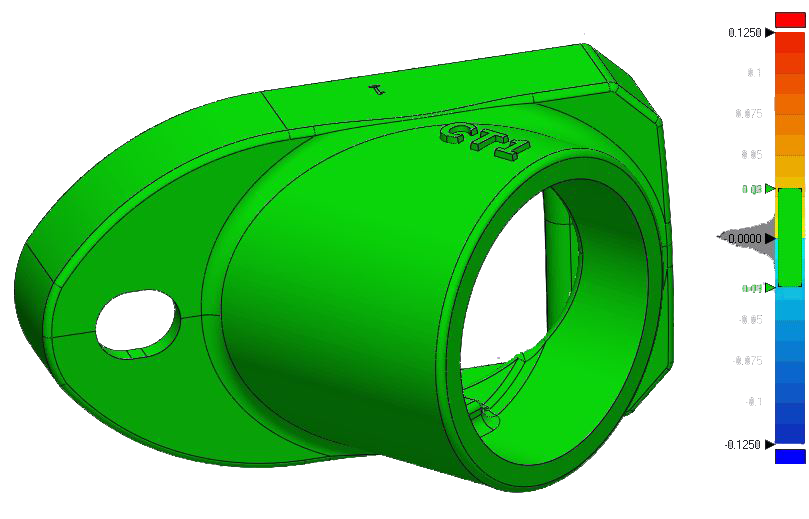

Case Study: Reverse Engineering Cast Products on an Expedited Timeline

Cem-Tec, a manufacturer of steel light poles in business since 1974, approached Eagle Alloy, Inc. with an emergency order. Due to an unforeseen supply-chain issue, they needed to find a new foundry to manufacture one of their popular products. With orders in and customers waiting, the clock was already ticking.

The following case study illustrates the steps Eagle Alloy followed to transfer casting of the product to our facility and to ensure that Cem-Tec had high-quality products ready for their customers as soon as possible.

Tags: Eagle Alloy, Case Study, Product Design, Development, Product Development

Getting Started with Airset Casting

Every manufacturer bringing a cast product to market must decide on the right casting process to use. Casting methods like shell molding, greensand casting, investment casting and airset casting all have their own sets of benefits and drawbacks. The right choice depends on the quantity being cast, the size of the part, and the requirements for dimensional accuracy, surface finish and material.

While it's not as widely used as shell molding or greensand casting, airset casting has plenty of advantages, and can be the perfect option for the right product.

Tags: Metalcasting, Eagle Alloy, Airset Casting

Case Study: Lean Manufacturing at Eagle Alloy

Eagle Alloy, Inc. was founded in 1979 and quickly grew from a short-run facility to a medium-to-high-production steel foundry. Despite the company’s success, its founders were not satisfied with the status quo. Having heard of developments in lean manufacturing, they decided to implement these tools in hopes of achieving greater efficiency, stability and quality throughout the production process.

5S: The Beginning

As with many production facilities beginning to experiment with lean manufacturing, Eagle Alloy started with 5S. 5S is easy to adapt to just about any environment, and the key to lean is customization. Every lean tool must be adapted to the particular type of production, to the size of the company and to the facility's space.

Tags: Lean Manufacturing, Eagle Alloy, Case Study

Numbers Don't Lie: Eagle Companies Achieve Huge Improvements in 2017

Two Eagle Group companies, Eagle Alloy, Inc., and Eagle CNC Technologies, Inc., have posted a series of personal bests and significant improvements across the board.

As you can see below, Eagle Alloy's achievements in 2017 include:

- 96.4% delivery – 2nd best in company history

- 1.87% scrap – BEST in company history

- 2.64% returns – Best in last 10 years

- 97.4% audit score – Best in last 8 years

- .27 PPM resulting in complaints – BEST in company history

Tags: Eagle Alloy, Efficiency, Eagle CNC

How Shell Molding Works: Step-By-Step Overview

We've already covered the history of shell molding, as well as a list of need-to-know terminology, so now it's time to start exploring how shell molding works. Keep in mind that this post presents a brief overview. We'll describe each step in more detail as we move along in the Introduction to Shell Molding blog series.

Tags: Shell Molding, Metalcasting, Processes, Eagle Alloy, Introduction to Shell Molding

Shell Mold Casting: Glossary of Terms

If you're familiar with metalcasting processes, you probably already know a lot of these words. Feel free to skip to the next post if you're feeling confident. But if you ask me, the same credo that applies to metal casting applies to learning about metal casting: "Better safe than sorry."

On the other hand, if you're knee-deep in casting terminology and can't seem to tell your risers from your ejector pins, this is the post for you. Read on for a primer on the terms and ideas involved in shell mold casting. We'll cover all of these concepts in more detail in later posts from the Introduction to Shell Molding series. Or, click below to download our printable Shell Mold Process Whitepaper.

Tags: Shell Molding, Metalcasting, Processes, Eagle Alloy, Glossary, Introduction to Shell Molding