Designing Cast Products: High-Tech Inspection for High-Quality Parts

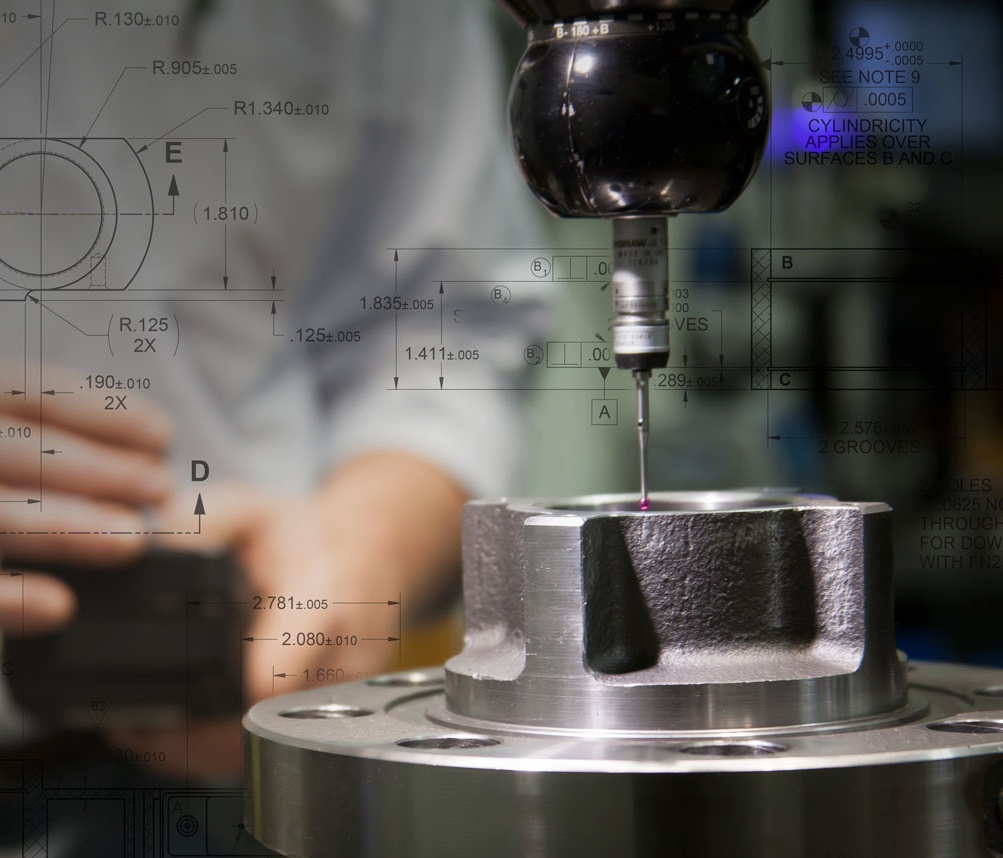

During the Eagle Group's product design process, sample runs of new cast products are subject to some of the most rigorous inspection processes available. The inspection methods we use prove to our customers that their parts will conform to specified tolerances and be free of defects. From magnetic particle inspection to laser scanning, we make sure that every new product passes a gamut of tests before it ships to the customer.

The Eagle Group regularly makes use of robust inspection technology to discover and diagnose any flaws or defects present in metal parts. In some cases, we use these methods to reverse engineer an existing part brought to us with defects. In other cases, we've pinpointed flaws in the initial design that lead to downstream manufacturing challenges.

Tags: Metrology, Inspection, Product Development

Designing Cast Products: 3D Modeling and Solidification Simulation Software

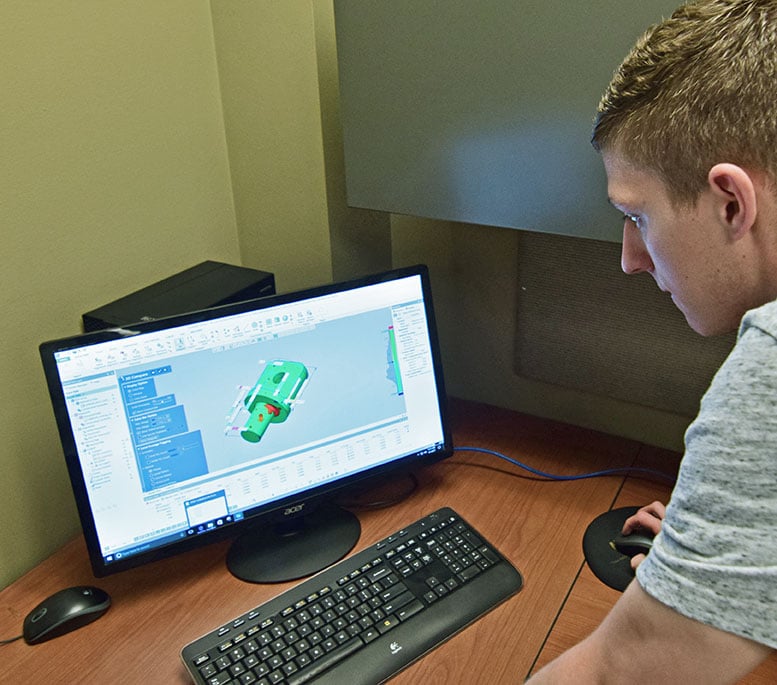

The rise of CAD/CAM software largely defines the current era of manufacturing. While blueprints and dimensional charts are still widely used as reference guides, modern manufacturers rely on software to design prototypes and simulate casting processes. One of the first steps in the cast part development process is to create a 3D model. From there, engineers can improve the part shape, simulate a variety of casting processes and materials, and troubleshoot difficult manufacturing scenarios.

When done right, CAD/CAM software enables foundries to solve all the problems of casting in the virtual world, before pouring any metal. The results are cost savings for the customer, time savings for everyone, and reduction of overall waste.

Tags: Product Design, Development, Capabilities, Inspection, Product Development, Technology, CAD/CAM

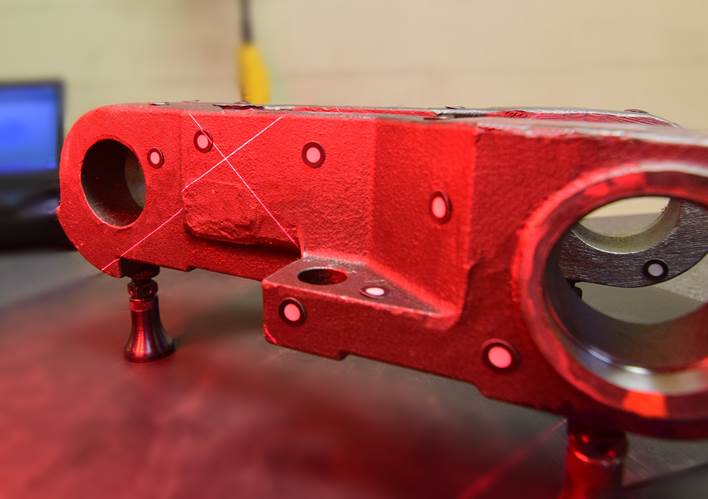

How Eagle Alloy's Handheld Laser Scanner Leads to Better Cast Products

Product development processes vary widely from foundry to foundry. The Eagle Group's Product Development blog series aims to highlight practices used by leading foundries that prioritize quality in every part they produce.

One product development practice that sets Eagle Alloy apart from other shell molding foundries is their use of a handheld laser scanner for inspection and dimensional reporting. This technology greatly improves the accuracy of dimensional reports, and makes it easier for customers to verify that new parts meet their requirements.

Tags: Metrology, Product Design, Development, Inspection, Product Development, Technology, 3D Scanning

Designing Cast Products: Starting the APQP Process with the Right Questions

APQP, or "Advanced Product Quality Planning," is a product-design process developed by automakers in the 1980s. Since then, a large number of businesses have adopted APQP for the product development stage.

A major portion of APQP is devoted to planning the production process, and making the right design decisions at an early enough stage to prevent expensive corrections later. When APQP is carried out correctly, it's a comprehensive and complete process. The foundry will engage the customer on multiple levels to learn everything they can know about the product, its end use and its working environment before finalizing design.

Tags: APQP, Product Design, Development, Product Development

5 Product Design Steps Your Cast Product Supplier Should Follow

One major factor that sets leading foundries apart from the rest is the product design process. Foundries that follow these five steps are much more likely to produce quality cast parts that function as expected, with low rates of returns and defects. They also frequently delight customers with innovative design suggestions and efficient processes that lead to better parts, lower costs and higher quality.

In the 1980s and 90s, product design procedures were so varied that major American automakers created a set of standard guidelines for their suppliers to follow. These manuals led to the modern practice of "Advanced Product Quality Planning," or APQP.

Tags: APQP, Product Design, Development, Product Development

Getting Started with the Eagle Group: What You Need to Know

The Eagle Group is comprised of three companies: a shell molding foundry, an investment casting foundry and a CNC machine house. Together, we're able to manufacture a broad range of metal products from concept to completion.

If you're looking for a new supplier for your raw or machined cast products, the Eagle Group could be the perfect fit. We pride ourselves on customer satisfaction, continuous improvement and outstanding work during all phases of the production process.

Tags: Metalcasting, Manufacturing, Product Design, Development, Capabilities, Product Development

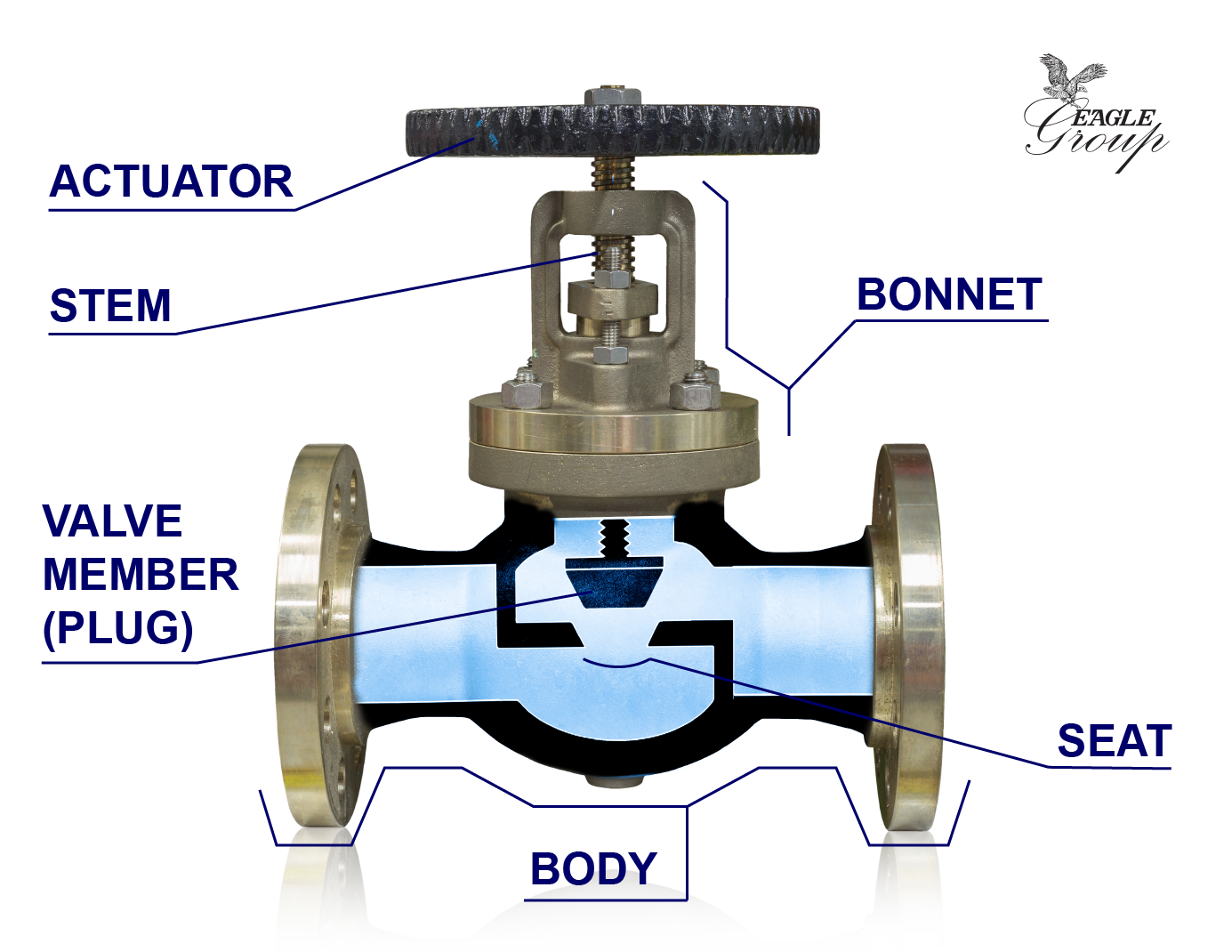

Anatomy of Industrial Valves

Controlling the flow of liquid, gas and sometimes solids, valves have a deceptively simple job. Like an on/off (or dimmer) switch for tangibles, every valve is designed and built to guide the movement of a specific material.

Industrial valves are used in thousands of products and systems, from water infrastructure to offshore oil rigs. Since they have such a wide variety of applications, it naturally follows that valves come in thousands, if not millions, of shapes and sizes. They also run the gamut from simple to highly complex.

Despite high levels of variation, most industrial valves can be broken down into the same basic components: body (or enclosure), bonnet, actuator, valve member and seat.

Tags: Valves, Valve Casting

Industrial Valve Types and Applications

Clockwise from top left: Globe valve, butterfly valve, gate valve, ball valve

Valves are employed in just about any situation involving the flow of liquid or gas. A valve controls the flow of water through your kitchen sink. A different valve brings propane gas into the burners of a gas stove. Outside the home, industrial valves are built to handle high pressure, either from fluid or gas, and to last through years of use in harsh environments. Most utilities, from water to oil and gas, wouldn't be able to function without heavy duty, industrial-strength valves.

Because many components of industrial valves are cast, foundries and machine shops like the Eagle Group often supply valve manufacturers with the parts they need to assemble finished products. The following valve types represent the most commonly seen valves for industrial applications around the world.

Tags: Manufacturing, Valves

What Precision Machine Shops Do: Milling

Milling is one of the most common processes in CNC machining, most likely because it is so versatile. Using a single tool, machine shops can create nearly limitless shapes on the surface of a workpiece. Milling can completely transform a piece of metal stock into a finished part of nearly any complexity.

The milling process in CNC machining consists of removing material with a rotating cutting tool. Unlike turning, the workpiece does not need to rotate in milling operations. In some cases, the workpiece will move linearly against a cutting tool; in other cases, the workpiece will remain stationary while the cutting tool moves.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Milling, What Precision Machine Shops Do

Stories from the Lean Manufacturing Journey

Eagle Alloy has been practicing lean manufacturing for close to a decade. Beyond the benefits to productivity and efficiency imparted by lean tools, Eagle companies have come to see lean manufacturing as part of their company culture. The inclusiveness, creativity and quality improvement they’ve been able to foster has paid off dividends, both in workplace atmosphere and customer retention.

Lean implementation makes a more dependable supplier

Almost all the way back at the beginning of Eagle Alloy’s lean journey, about six months into their implementation of cellular manufacturing, the company was already seeing a noticeable productivity boost. They came into contact with a potential customer—we’ll call them Company A—who scheduled a shop tour at Eagle Alloy. Company A was already a successful manufacturer, but their casting supplier had recently gone bankrupt and they were looking for a replacement.