Getting Started with Permanent Mold Casting

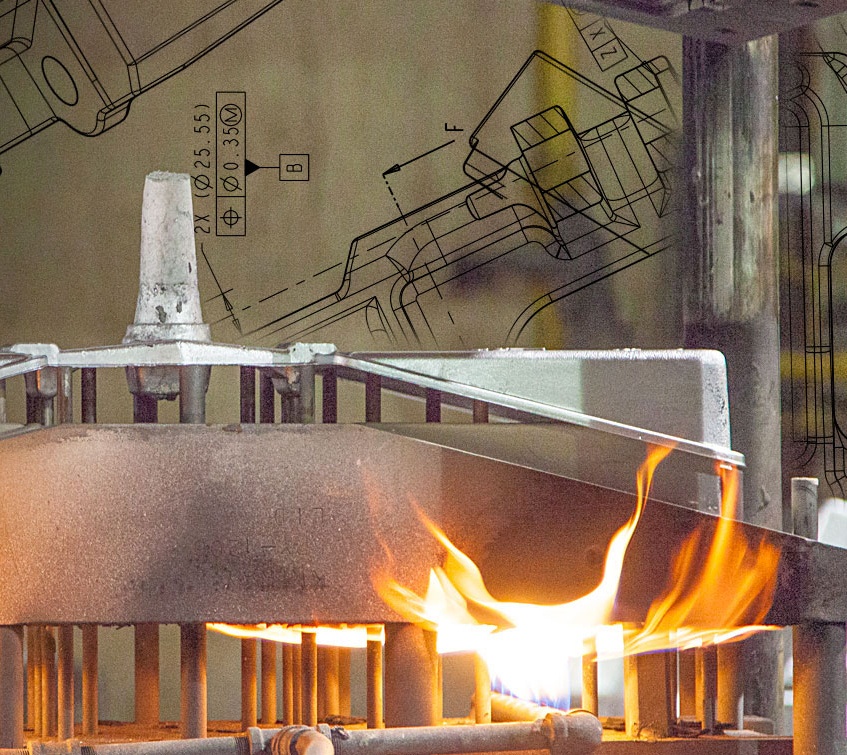

Permanent mold casting is a type of metalcasting involving reusable molds. Whereas other casting methods, like sand casting and investment casting, use disposable molds, permanent molds last much longer and can be used to produce hundreds, or even thousands, of identical parts.

Every project can be matched with the ideal casting method. For non-ferrous castings with medium-to-high volumes, permanent mold casting offers a long list of advantages.

Tags: Metalcasting, Aluminum Casting, Eagle Aluminum, Permanent Mold Casting

Getting Started with Airset Casting

Every manufacturer bringing a cast product to market must decide on the right casting process to use. Casting methods like shell molding, greensand casting, investment casting and airset casting all have their own sets of benefits and drawbacks. The right choice depends on the quantity being cast, the size of the part, and the requirements for dimensional accuracy, surface finish and material.

While it's not as widely used as shell molding or greensand casting, airset casting has plenty of advantages, and can be the perfect option for the right product.

Tags: Metalcasting, Eagle Alloy, Airset Casting

Join Us at the Wings of Mercy Fundraiser – Saturday, June 9th at the Muskegon County Airport

Wings of Mercy is a charitable organization based in West Michigan that flies patients to their medical destinations who would not otherwise be able to travel there. Pilots and plane owners donate their time for each mission.

In 1991, Mark, Wayne Jarvis and I chose to offer our company plane to fly patients that Wings of Mercy would refer to us. Since then we have flown over 246,000 miles (about 10 times around the world) and over 1400 hours in the air. We have flown 361 flights since 1991 for Wings. Most flights are to Rochester, MN where the Mayo Clinic is located. We have also flown patients to Denver (a pediatric asthma specialist), Raleigh, NC (lung transfer specialists), Baltimore, Florida, Pennsylvania, Maine, Massachusetts, as well as many other locations. Wings of Mercy, and their 30 other planes and pilots, fly about 225 charitable flights per year.

Tags: Healthcare, Charity, Community

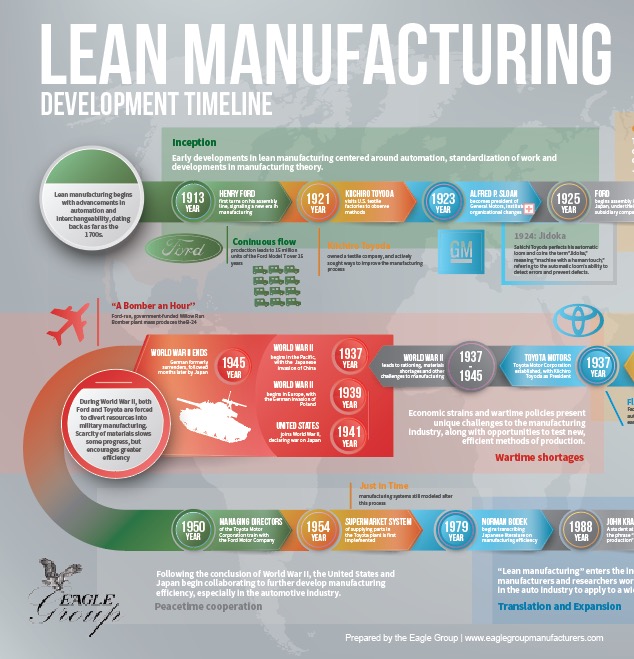

Infographic: Lean Manufacturing Timeline

The history of lean manufacturing dates back at least to the 1700s, when Eli Whitney developed interchangeable parts in order to deliver a massive order of muskets to the American Army.

It wasn't until 1988 that John Krafcik coined the phrase "lean manufacturing" in his research as an MIT student. For most of the 20th century, lean manufacturing was tied closely to industrial innovations in the United States and Japan. While it wasn't called "lean" for many decades, American and Japanese automakers laid the groundwork for the tools of lean manufacturing that we use today.

What Precision Machine Shops Do: Turning

Turning has been practiced by machinists for centuries on many different materials. Originally, turning acted on wood to create complex, cylindrical designs for use in tools, handles, furniture. Today, turning is a vital part of the metal manufacturing process, and a major technique used by precision CNC machine shops in the United States and around the globe.

Turning is the process of rotating a workpiece and bringing it into contact with a cutting tool. As the workpiece turns, the rotating motion forces the cutting tool to strip away material. The cutting tool itself can move linearly, either parallel or perpendicular to the axis of the spinning workpiece. Cuts made in turning, and the resulting shape of the workpiece, are determined by the motion and shape of the cutting tool.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Turning, Lathe, What Precision Machine Shops Do

What Precision Machine Shops Do: Introduction

Our new blog series What Precision Machine Shops Do focuses on the processes, equipment and knowledge involved in modern machining. We'll take a close look at key metal removal techniques like milling, turning, facing, boring and tapping, along with the many products and parts that work as a result of these processes.

For the most part, we'll be discussing CNC machining, or Computer Numerical Control machining. For a brief introduction to CNC, explaining how it developed and how it differs from non-CNC machining, check out our Introduction to CNC Machining blog post.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

How Investment Casting Compares to Other Metalcasting Methods

Tags: Metalcasting, Processes, Investment Casting

Aluminum Casting vs. Steel Casting: Choosing the Right Alloy for Your Cast Products

In modern metalcasting, steel and aluminum are two contenders for the top material of choice. Thousands of manufacturers around the world rely on both metals to produce strong, light and corrosion-resistant metal parts and products.

You'll find hundreds of different grades and alloys for both steel and aluminum, and each has its specific advantages and disadvantages. For this comparison, we'll focus on differences between aluminum and steel alloys in general, rather than zooming in on differences between specific alloys.

Tags: Metalcasting, Machining, Aluminum Casting, Aluminum, Materials

Onsite Clinics: Taking Employee Healthcare to the Next Level

Manufacturing doesn't work without people. Equipment operators, engineers, sales teams and managerial staff are responsible for the success of every manufacturing business. Just like there's no company without people, there's no healthy business without healthy employees.

With healthcare costs constantly on the rise, employee healthcare is a major expense for businesses of all sizes. Traditionally, companies have a limited scope of choices to make when it comes to healthcare. Most choose to either subsidize health insurance for their employees, or form a self-funded insurance group.

A third option, which is increasingly gaining popularity, is to host onsite health clinics. These clinics can offer easier access to healthcare and more control over healthcare costs–but onsite clinics aren't right for every business. Here, we explore some of the advantages and disadvantages of hosting onsite clinics.

Investment Casting Guide Ebook: New Eagle Group Resource for Manufacturers

Eagle Precision Cast Parts, Inc. just released a downloadable resource, titled Investment Casting Process Guide: A Comprehensive Introduction to Investment Casting.

The goal of the 21-page ebook is to make it easy for manufacturers, and anyone else who's interested, to learn the basics of investment casting. Manufacturers looking for a better way to produce parts can find information on tolerances, design recommendations and a full case study.

Tags: Metalcasting, Investment Casting, Eagle Precision, Investment Casting Guide