AJ Menefee

Recent Posts

Think Like an Owner: How ESOP Builds Innovation and Workforce Empowerment

ESOP is a way to transfer company ownership from one generation to the next—in many cases, this transfer happens when the original owners sell their stake in the company to their own employees. ESOP stands for Employee Stock Ownership Plan, but the acronym hardly conveys the potential of this empowering ownership model. That’s because ESOP is more than just a financial structure—it has the potential to shape company culture, fueling innovation, driving accountability and making an appreciable difference in the quality of customer relationships.

Our slogan at Eagle Precision is “Think Like an Owner,” which is a direct reference to our ESOP structure, and aims to boost awareness among our employees of the benefits we all share. Our employees are our company owners, and adopting that mentality has already led to a slew of innovations and improvements in our daily operations.

Tags: American Manufacturing, Eagle Group Values, Eagle Precision, ESOP, Employees, Human Resources

New Article in Modern Casting Magazine: Modular Automation at Eagle Precision

Automation in investment casting is often seen as the domain of large-scale foundries, with a common perception that it requires major capital investment, significant floor space, and rigid shop-floor layouts. But what if there were a way to bring the benefits of robotic automation to foundries of any size?

Tags: Eagle Precision, Capabilities, Equipment

Tooling for Investment Casting

Tooling in metalcasting and CNC machining refers to reusable items that are specific to each job. In investment casting, tooling is considered to be wax-injection dies used to create wax patterns. If you're familiar with how investment casting works, you already know that these wax patterns form the basis of the investment casting process. Each part begins as a wax pattern, and the properties of wax – smooth surface, low melting temperature and excellent flow properties – that make highly complex investment castings possible.

Tags: Investment Casting, Tooling

Casting Advocates: Get to Know AFS

In our blog series, Casting Advocates, we get to know organizations and industry leaders who work to elevate the metalcasting profession. This installment focuses on the American Foundry Society (AFS).

The American Foundry Society is a national organization with a mission to "advance the success of its members and the metal casting industry through advocacy, education and innovation." In support of this mission, AFS works constantly to support technical innovation, advocate for beneficial policies, promote positive perception of the industry, develop workforce skills and provide a range of services and networking opportunities for casting facilities.

Tags: Education, Community, Casting Advocates, Trade Associations

The Rise of Robotics in Metalcasting and Machining

The use of robotics in manufacturing, including metalcasting and machining, has grown steadily since the 1970s. Industrial automation increasingly relies on robotics as a way to improve efficiency and replace monotonous, repetitive human tasks.

Robots are used for a wide variety of tasks in manufacturing, from transportation to assembly. In metalcasting and machining, robots can be used to complete nearly any programmable task, from dipping and pouring to grinding and milling.

Tags: Eagle Alloy, Eagle Precision, Robotics

5 Product Design Steps Your Cast Product Supplier Should Follow

One major factor that sets leading foundries apart from the rest is the product design process. Foundries that follow these five steps are much more likely to produce quality cast parts that function as expected, with low rates of returns and defects. They also frequently delight customers with innovative design suggestions and efficient processes that lead to better parts, lower costs and higher quality.

In the 1980s and 90s, product design procedures were so varied that major American automakers created a set of standard guidelines for their suppliers to follow. These manuals led to the modern practice of "Advanced Product Quality Planning," or APQP.

Tags: APQP, Product Design, Development, Product Development

Foundry in a Box: Bringing Metalcasting to the Classroom

Ask a group of 5th graders what they want to be when they grow up, and you'll get a long list of answers: firefighter, detective, athlete, musician, astronaut. These (and other top kids' dream jobs) are certainly vital to our society, but as proud and forward-thinking manufacturers, we have to ask: Wouldn't you rather be a metal caster, or a machinist, or a Six Sigma coach?

Maybe the answer is "yes," but the issue is that not many kids have been asked this question. That's where programs like Foundry in a Box come in. Dedicated professionals in the manufacturing industry visit schools and introduce students to the basics of metalcasting, and manufacturing careers, through hands-on projects. Programs like this not only expand students' horizons, but they're also vital to the future of manufacturing in the United States.

Tags: Metalcasting, Foundry in a Box, Education

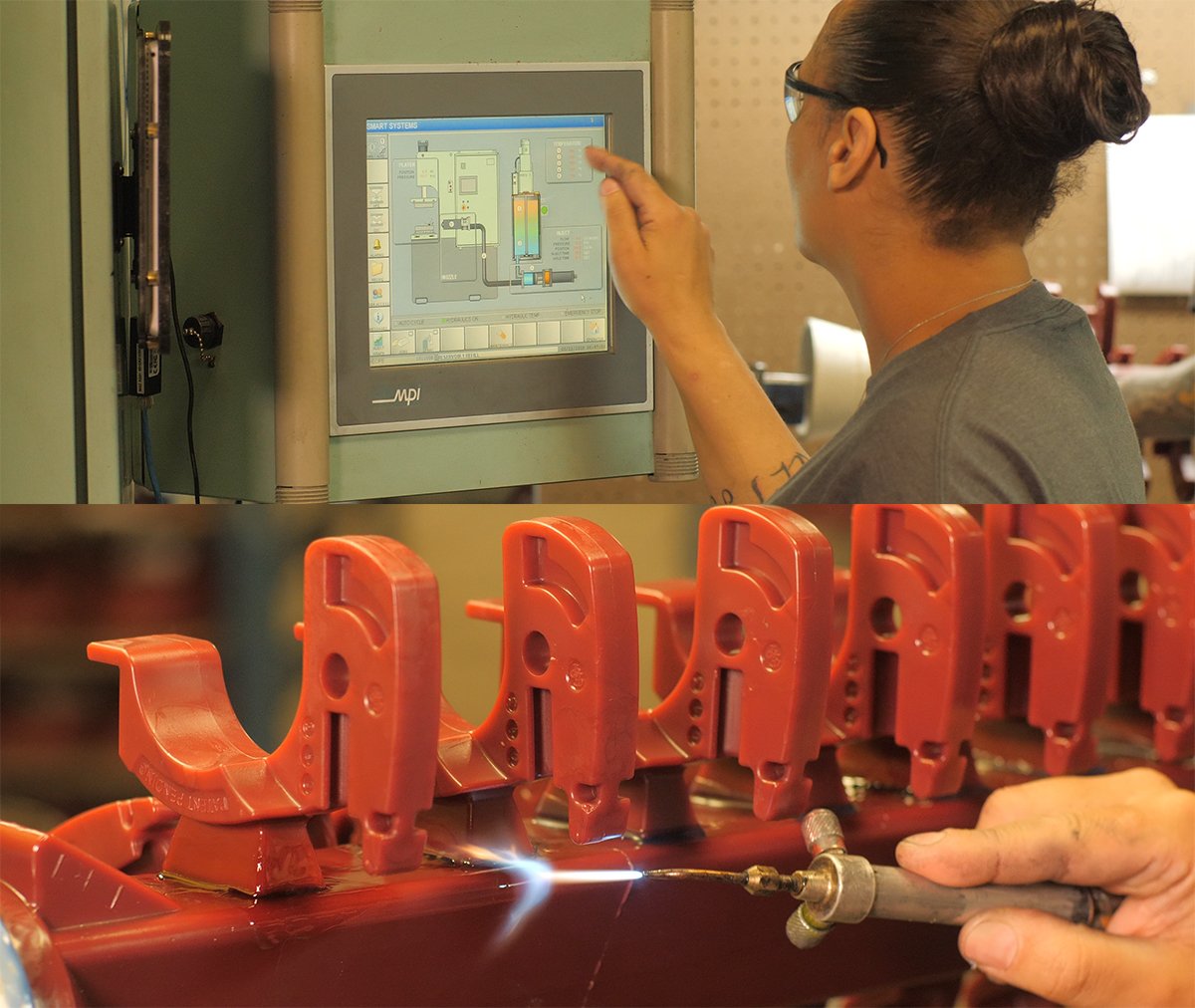

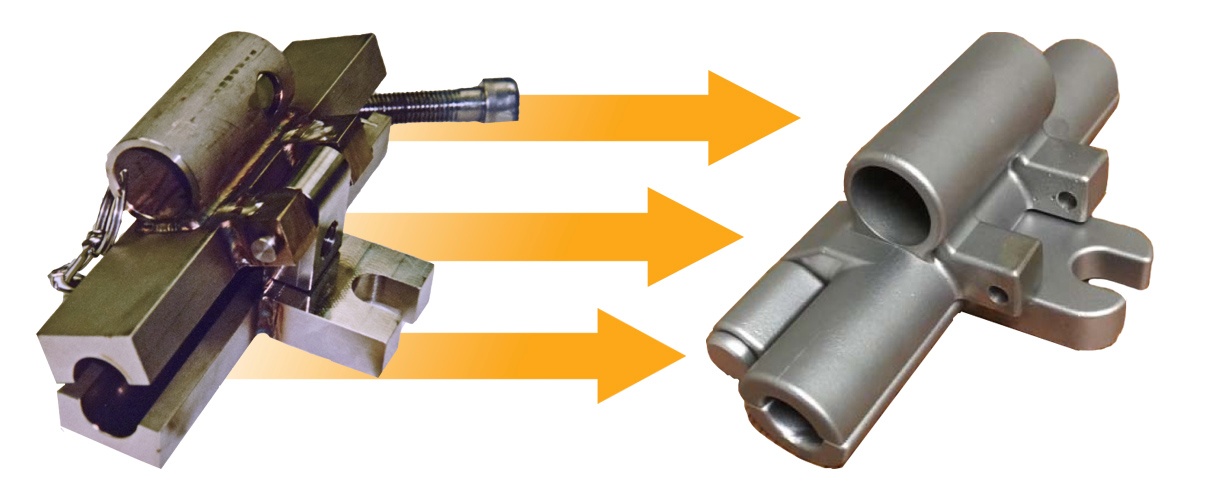

One Part's Journey from Fabrication to Casting

It all started on a routine facility tour

While touring a client’s facility, representatives of Eagle Precision Cast Products noticed a cable clamp assembly–a relatively complex fabricated part that they believed would be an excellent candidate for fabrication to casting conversion.

Tags: Metalcasting, Processes, Fabrication to Casting, Fabrication, Fab-Casting, Investment Casting, Case Study

3 Quick Tips for Buying Cast Parts

Whether you're looking to produce a new product or save money on products you're already manufacturing, cast parts can be a great option. Metalcasting has been around for over 5,000 years, and today's processes, along with cnc machining, can produce just about any part imaginable.

Tags: Metalcasting, Machining, Buyer's Guide, Tips