The Rise of Robotics in Metalcasting and Machining

The use of robotics in manufacturing, including metalcasting and machining, has grown steadily since the 1970s. Industrial automation increasingly relies on robotics as a way to improve efficiency and replace monotonous, repetitive human tasks.

Robots are used for a wide variety of tasks in manufacturing, from transportation to assembly. In metalcasting and machining, robots can be used to complete nearly any programmable task, from dipping and pouring to grinding and milling.

Tags: Eagle Alloy, Eagle Precision, Robotics

Eagle Alloy, Inc. Recognized as a John Deere “Partner-Level Supplier”

Eagle Alloy, Inc. has earned recognition as a Partner-level supplier for 2018 in the John Deere Achieving Excellence Program. The Partner-level status is Deere & Company’s highest supplier rating.

Eagle Alloy was selected for the honor in recognition of our dedication to providing products and services of outstanding quality as well as our commitment to continuous improvement.

Tags: Awards, Eagle Alloy, Recognition

What Precision Machine Shops Do: Boring

Boring may not sound like a very exciting topic, but don't let names deceive you: boring is one of the most widely used techniques in machining, and one of the most reliable ways to finish holes.

Boring is the process of enlarging and finishing pre-existing holes. The holes might have been cast, drilled or otherwise formed to a rough state, but boring is often the best technique to provide the accuracy and repeatability expected of CNC machined parts.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

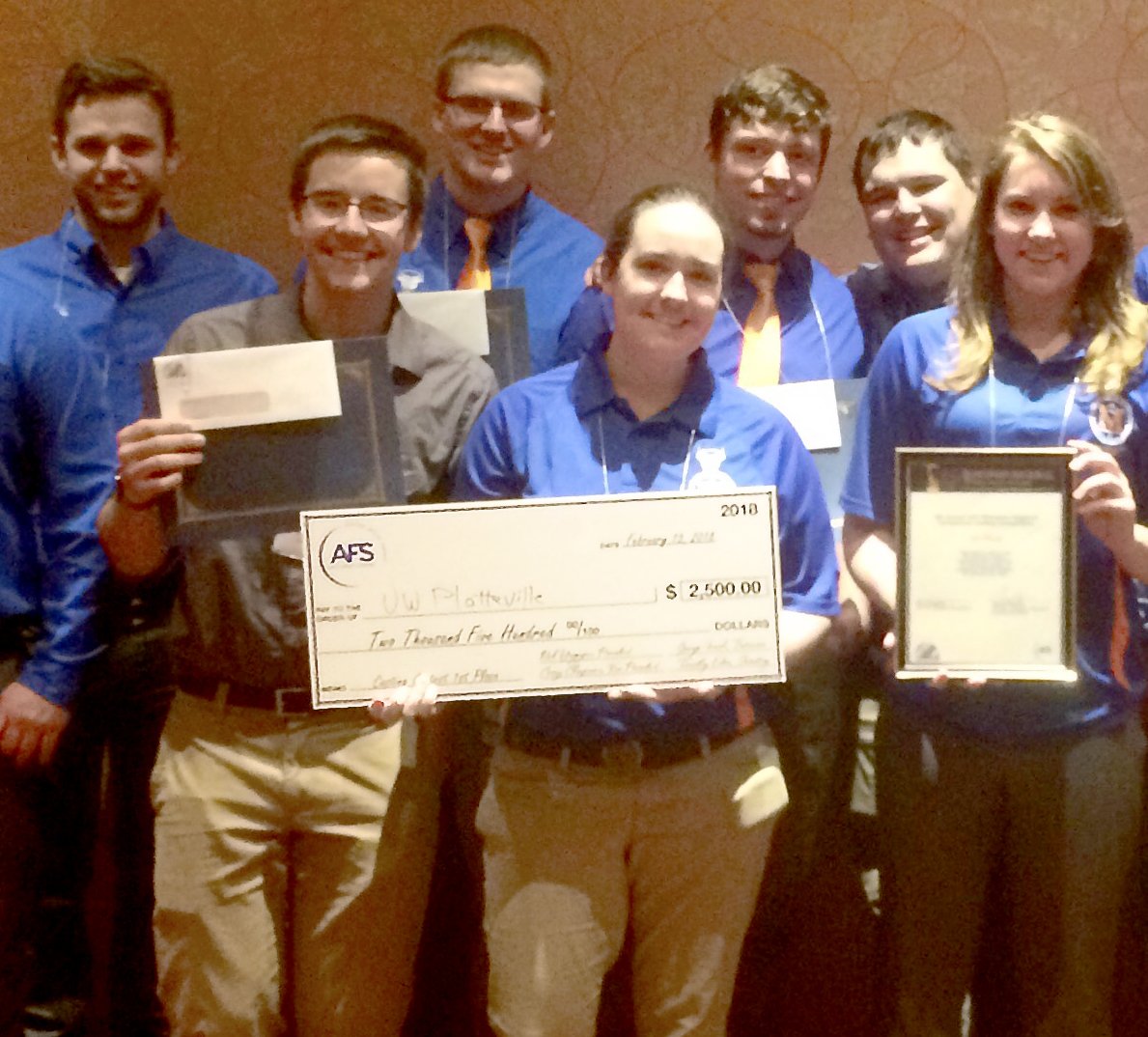

Coming Soon: AFS Regional Student Casting Competition

Forget about the Rose Bowl–this year's college competition to watch is coming up in February!

The AFS Wisconsin Regional Invitational Casting Competition will host casting teams from colleges and universities around the Midwest. Taking place during the AFS Wisconsin Regional Expo and Conference, the event invites student teams to present cast products they've created using school casting facilities. All projects in competition were completed by members of AFS student chapters.

Tags: Metalcasting, Students, Student Metalcasting Competition

Introduction to Greensand Casting

Greensand casting is a time-tested and highly versatile metalcasting process. Different foundries use different methods and materials, but greensand casting always involves creating molds by compacting moist, organically bonded sand around patterns. Whereas shell molding uses heat-bonded sand and no-bake casting uses chemically bonded sand to form molds, greensand casting is unique in that sand is bonded through naturally occurring compounds–in most cases, the bonding agent is clay.

Eagle Aluminum Cast Products makes use of greensand casting to produce large aluminum castings. The greensand process is very customizable and capable of manufacturing nearly any type of cast product. Here, we'll explore the processes, casting characteristics, benefits and challenges of the greensand casting process.

Tags: Metalcasting, Processes, Eagle Aluminum, Greensand Casting

Induction Melting at Eagle Alloy

At Eagle Alloy, we recently expanded our capabilities by investing in three new Inductotherm induction melting furnaces. Since opening in 1979, we’ve always used induction for melting because of its efficiency and flexibility in comparison to other heating methods. These new furnaces allow us to increase our melting capacity both now and in the future.

It's easy to agree with Inductotherm when they say that "watching a piece of metal in a coil turn cherry red in a matter of seconds can be surprising to those unfamiliar with induction heating." The process of induction heating is as fascinating as it is useful. Here, we explore the origins of induction heating and its applications in metalcasting.

Tags: Capabilities, Melting, Induction

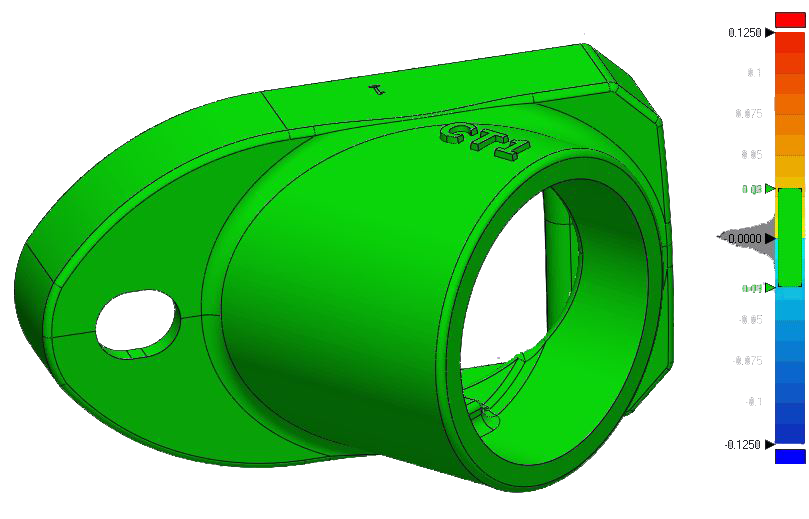

Case Study: Reverse Engineering Cast Products on an Expedited Timeline

Cem-Tec, a manufacturer of steel light poles in business since 1974, approached Eagle Alloy, Inc. with an emergency order. Due to an unforeseen supply-chain issue, they needed to find a new foundry to manufacture one of their popular products. With orders in and customers waiting, the clock was already ticking.

The following case study illustrates the steps Eagle Alloy followed to transfer casting of the product to our facility and to ensure that Cem-Tec had high-quality products ready for their customers as soon as possible.

Tags: Eagle Alloy, Case Study, Product Design, Development, Product Development

Eagle Alloy Honored as Michigan Manufacturer of the Year

Originally published on MIMFG.org here

The Michigan Manufacturers Association (MMA) is proud to announce Eagle Alloy of Muskegon has been selected as the 2018 recipient of the John G. Thodis Michigan Manufacturer of the Year Award. A prestigious honor since 1981, the award is named after MMA’s longest-serving president and honors the important, positive and tangible contributions individual manufacturers make to their employees, customers and communities. The Eagle Alloy team received the award during the 2018 MFG Excellence Awards on November 8 at the Kellogg Center in East Lansing.

Tags: Awards

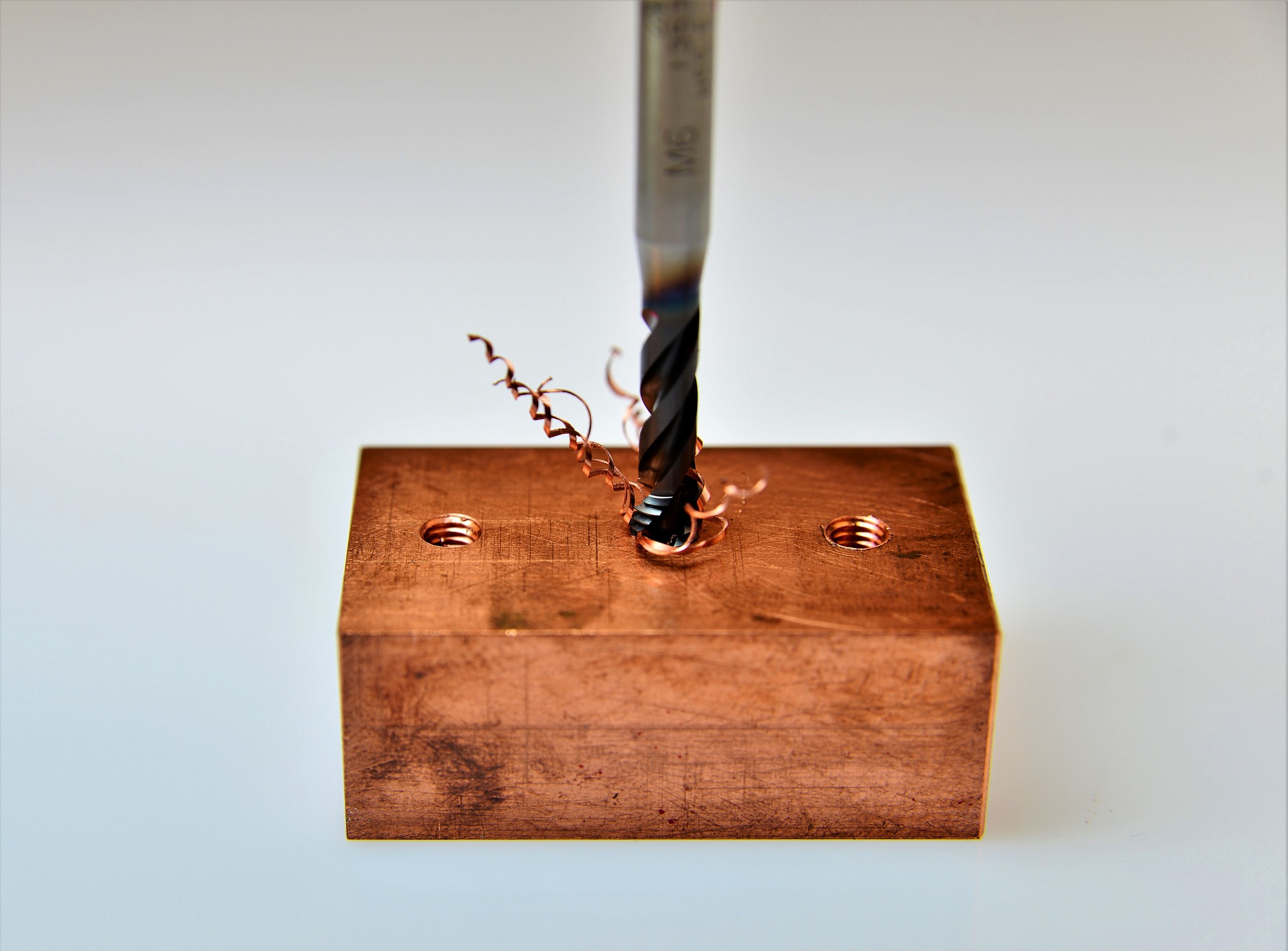

What Precision Machine Shops Do: Drilling

Drilling is one of the most common techniques used in manufacturing to create holes. In contrast to other hole-making methods like boring, reaming and tapping, drilling is most often used to create holes in unbroken surfaces. In precision CNC machining, drilling can range in scope from simple, rough hole drilling to complex, multi-feature hole drilling.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

Manufacturing Day 2018 at Eagle Alloy: Event Recap

Eagle Alloy was lively and bustling on Thursday, October 4th. That's no surprise: our Muskegon, MI campus is regularly buzzing through three shifts a day, five days a week. But this particular day brought in a larger crowd than usual: in celebration of Manufacturing Day 2018 we opened our campus to local schools and community representatives for a demonstration of modern metalcasting.

The goal of Manufacturing Day is to inspire the next generation of manufacturers, and we wanted to support that goal any way we could. By inviting students to witness our work firsthand, we aimed to provide an introduction to modern metalcasting and manufacturing. After nearly 40 years in business, we understand the importance of letting young people know about the exciting potential of metalcasting careers.

Tags: Metalcasting, Education, Community, Manufacturing Day, Event