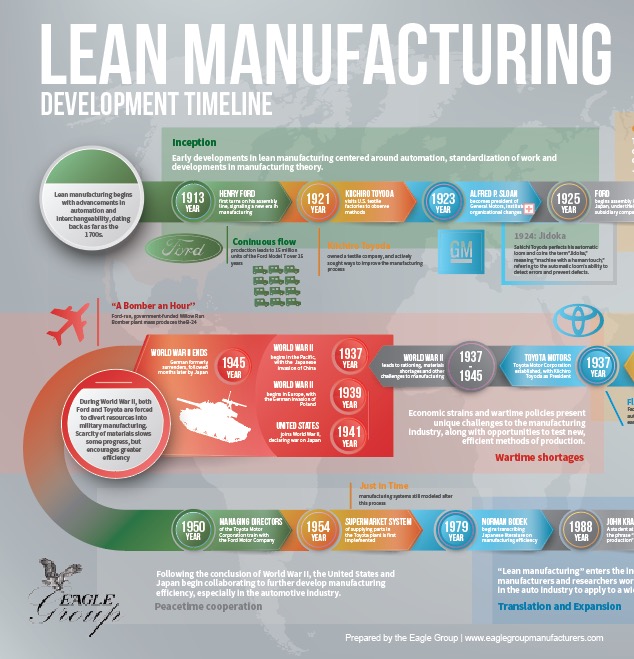

Infographic: Lean Manufacturing Timeline

The history of lean manufacturing dates back at least to the 1700s, when Eli Whitney developed interchangeable parts in order to deliver a massive order of muskets to the American Army.

It wasn't until 1988 that John Krafcik coined the phrase "lean manufacturing" in his research as an MIT student. For most of the 20th century, lean manufacturing was tied closely to industrial innovations in the United States and Japan. While it wasn't called "lean" for many decades, American and Japanese automakers laid the groundwork for the tools of lean manufacturing that we use today.

This Lean Manufacturing Timeline from the Eagle Group focuses on the major innovations of American and Japanese manufacturers–namely Ford, GM and Toyota–in their quest for efficiency, quality and consistency. In addition to the visual history of lean manufacturing, the document provides a brief introduction to lean concepts, and a list of modern lean tools and strategies.

The story doesn't end with this timeline. Lean manufacturing is still a major area of academic study and manufacturing practice. Every year lean tools are modified, improved and added to the library. As more businesses adopt these practices, the future is looking leaner every day.

Click below to download the Lean Manufacturing Timeline:

Click here for more on lean manufacturing from the Eagle Group Blog

Tags: Lean Manufacturing, Manufacturing, Efficiency

Written by Jeff Cook

Jeff Cook is Chief Sales and Marketing Officer for Eagle Alloy in Muskegon, MI. While enlisted in the Marine Corps Reserves, he began working at Eagle Alloy in 1986 as a snag grinder on 3rd shift after his father told him to “Get a job!” Jeff is past President of the American Foundry Society. His passions include educating young people on the careers and advancement available in the metalcasting industry.