5 Product Design Steps Your Cast Product Supplier Should Follow

One major factor that sets leading foundries apart from the rest is the product design process. Foundries that follow these five steps are much more likely to produce quality cast parts that function as expected, with low rates of returns and defects. They also frequently delight customers with innovative design suggestions and efficient processes that lead to better parts, lower costs and higher quality.

In the 1980s and 90s, product design procedures were so varied that major American automakers created a set of standard guidelines for their suppliers to follow. These manuals led to the modern practice of "Advanced Product Quality Planning," or APQP.

In recent decades, APQP has been translated and improved by a number of manufacturing sectors, and its principles form the core of product-design best practices. Not all suppliers are bound to follow APQP manuals, and many certainly do not. However, the following five steps are closely tied to APQP. Foundries with a dedication to quality and constant improvement will follow these steps during the design process, separating them from less dependable foundries.

1. Initial product design: comprehensive quoting

When a customer first approaches a new metal casting supplier, they usually have a good idea of what they want to cast and how many pieces they want to order. To further aid in design, customers can provide a wide range of materials: 2D blueprints, 3D CAD models, plastic models or real-world parts taken from a previous supplier's run.

The foundry should assess all costs involved in delivering the product in order to provide a comprehensive and accurate quote. Costs may include refining the product design, tooling, overhead at the casting facility, materials, and any other incidental costs related to the specific product. Once all the numbers are in, the foundry should provide a quote to the customer. If accepted, the foundry can move forward in the APQP process.

Find out what it's like to start working with the Eagle Group

2. Ask the right questions with an APQP checklist

In order to learn as much as they can about the product they'll be casting, experienced foundries start the APQP process with a comprehensive set of questions. They consult the customer to learn as much as they can about the product's appearance, requirements and end use. Foundry engineers should start with a standard APQP checklist, and expand on it according to the specific part.

Basic APQP checklist questions include:

- What is the end use of the part?

- Are there regulatory requirements?

- Does the current product have any tolerance issues?

Non-standard APQP checklist questions include:

- What corrosive substances will the product be exposed to?

- What level of conductivity is required?

3. Use design and simulation software

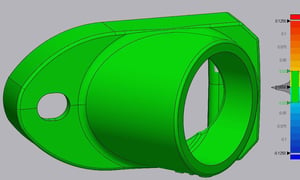

Whether a customer provides a 3D model or not, the foundry should have one on hand before moving forward in the product-design process. Eagle Group foundries use Solid Edge, SolidWorks and Cimatron 3D modeling software to create, edit and improve part designs. When finished, the 3D model represents an ideal version of the product exactly in the middle of the tolerance range.

Whether a customer provides a 3D model or not, the foundry should have one on hand before moving forward in the product-design process. Eagle Group foundries use Solid Edge, SolidWorks and Cimatron 3D modeling software to create, edit and improve part designs. When finished, the 3D model represents an ideal version of the product exactly in the middle of the tolerance range.

The foundry can then take that 3D model and use it as the basis for solidification simulation. Industry software, like MAGMASOFT, shows how metal will behave inside a mold as it cools. The software allows operators to experiment with hundreds of different parameters–like riser locations and pouring temperatures–to determine the best possible combination.

4. Test a sample run

The foundry can use data from solidification software to order patterns and coreboxes that take into account the gating as well as the part. After receiving the tooling, the foundry produces molds and carries out a sample run. Leading foundries then carry out a long list of tests to ensure that the parts are within the tolerance range and free of defects.

Measurements, either taken manually or using a CMM, determine whether the products are within the tolerance range. Modern foundries can also use laser scanners, which provide a range of benefits to the supplier and the customer. Other testing, including physical inspections, X-Rays and Magnetic Particle Inspection (MPI), might also be administered to ensure that there are no defects.

Tip: look for a foundry with a robust quality control department: the more a foundry cares about quality, the greater their testing capabilities will be.

5. Provide a comprehensive sample report

If your supplier finishes the sampling phase by simply sending you a note that they're "good to go," it might be time to look for a new foundry.

Foundries that put the time and effort into developing the best possible product with the most efficient manufacturing plan naturally want to share that information with the customer. According to Eagle Alloy CTO Nic Tarzwell, the sample report for a new product often amounts to over 20 pages, including the APQP checklist, measurements, digital scans, error reports and photos. Major purchasers, especially in the auto industry, often require comprehensive APQP reports like this. The best foundries supply them to all customers, regardless of requirements.

Along with the actual sample parts, the customer should have all the information they need to give the foundry the go-ahead.

As soon as the customer approves, the foundry can begin production.

The Eagle Group's product design process has won praise from customers and resulted in consistent part quality for decades. To learn more about working with us, download our Quick Reference guide:

Tags: APQP, Product Design, Development, Product Development

Written by AJ Menefee

AJ Menefee is VP of Technical & Engineering at Eagle Precision Cast Parts in Muskegon, MI.