Imagine a World Without Steel Casting Supply Issues

We don't have to say how good we are. Our customers do it for us!

Every six months, Eagle Alloy invites customers to fill out a survey rating their satisfaction with our services. We ask about every aspect of the supplier-customer relationship, from answering phone calls and emails to on-time delivery. Our company was founded in 1979 with a goal of providing high-quality castings and superior customer service; customer feedback is invaluable to us as we seek to better align our activities with our guiding principles.

Tags: Eagle Alloy, Testimonials

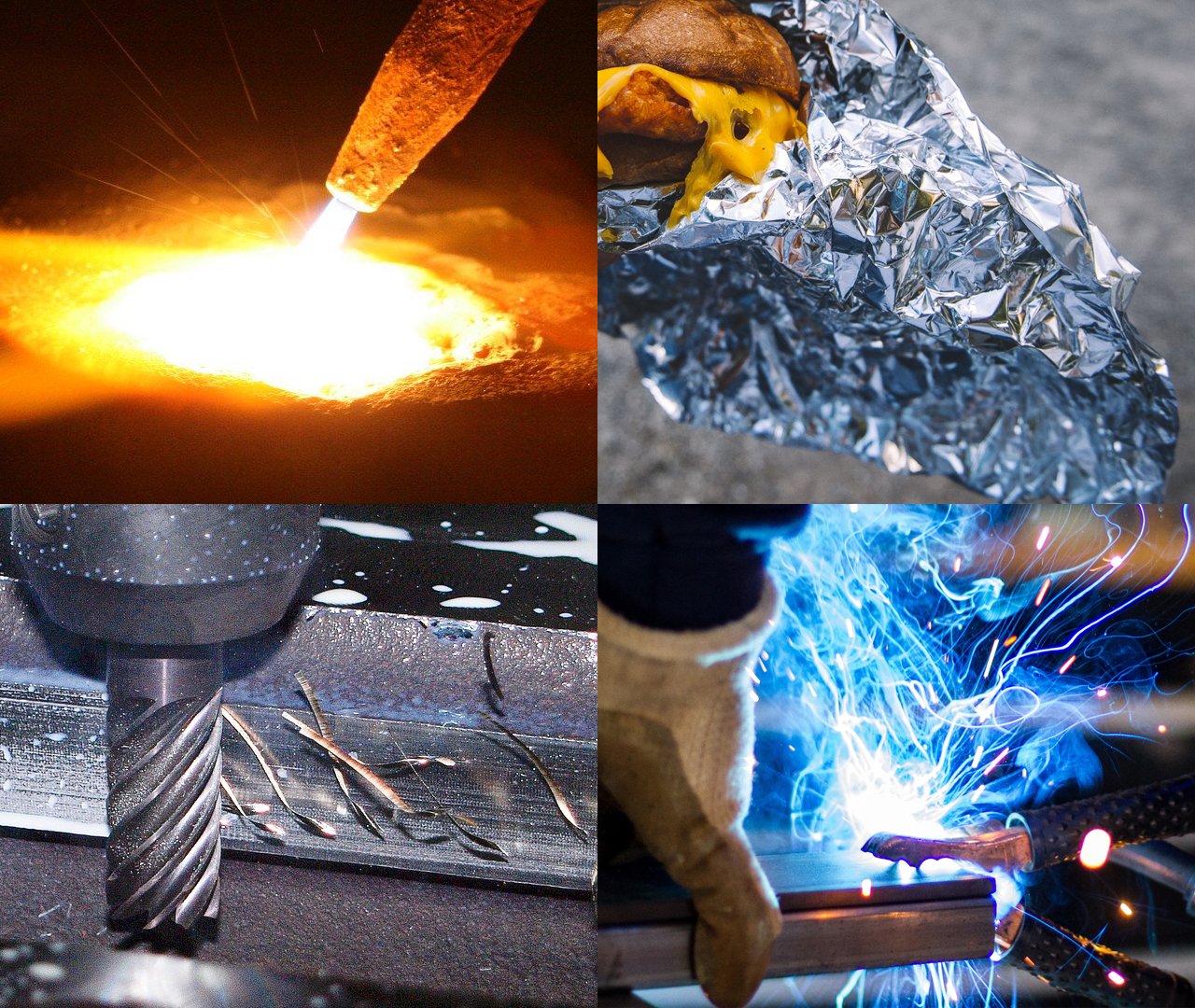

Learn to Speak Our Language: Metalcasting & CNC Machining Jargon

Metal manufacturing professionals are a close-knit community, and just like any specialized group, we've developed our own way of speaking. To outsiders, many of whom are our friends, family and customers, metalcasting & machining lingo might seem like another language entirely. Here, we aim to demystify metalcasting & machining jargon so anyone can join the conversation.

Tags: Metalcasting, Glossary, CNC Machining

Weld Repair Done Right

Eagle Group casting facilities consistently receive top marks in customer satisfaction, scrap rates and return rates, but even with our commitment to quality and rigorous product development process, our castings occasionally require post-solidification adjustments prior to delivery. "Across all of our 2,000-plus part numbers, under 10% of castings fall out for repair," according to Eagle Alloy Chief Sales Officer, Jeff Cook, "and some part numbers have 1% or less." While the percentage is small, the cost of scrapping repairable defects can raise part price and delay delivery. For those reasons, many world-class casting facilities strongly recommend that customers allow weld repair at the foundry's discretion.

Tags: Casting Defects, Welding

Overview of Mechanical Properties of Metals

In the metal manufacturing industry, mechanical properties play a huge role when choosing the right alloy for each job. Throughout casting and machining processes, as well as during the product's useful life, the chosen material will be subject to many external forces. It’s up to the manufacturers to create products that perform as needed every step of the way. By understanding mechanical properties, manufacturing professionals can make the right choices for materials and processes.

Tags: Materials, Metals, Metallurgy, Metal Properties, Mechanical Properties

Eagle Alloy Unveils New Customer Training Center

MUSKEGON, MI - MAY 27, 2020 – Eagle Alloy is proud to announce our newly completed Multimedia Training Center. This facility will allow us to provide our customers with state-of-the-art training to go along with our plant tours and project discussions. Groups of up to 24* can relax and take in training and introductory presentations by our Sales, Engineering, Quality and Production department staffs.

Tags: Eagle Alloy

Overview of Physical Properties of Metals

Physical properties are an important way of distinguishing one material from another. In the study and application of metallurgy, physical properties are often considered a broader category than mechanical properties, but not all properties overlap. Physical properties are most easily distinguished from mechanical properties by the method of testing. While mechanical properties require forces to be applied to obtain a measurement, physical properties can be measured without changing the material.

Tags: Materials, Metallurgy, Metal Properties

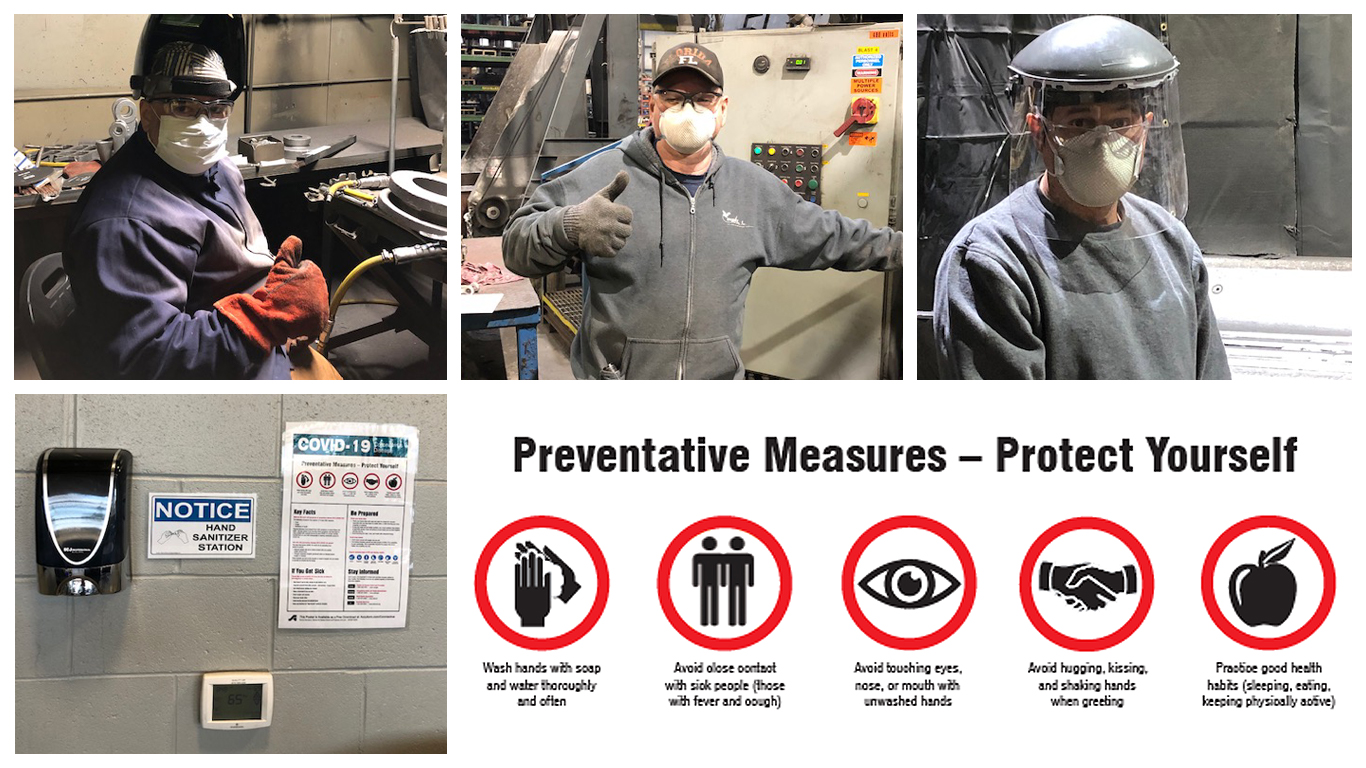

Staying Open Through COVID-19: Advice from an Essential Business

Operating as an essential business during the COVID-19 crisis is both an honor and a challenge. While Eagle Group companies have maintained continuous production, we have made a number of changes to our daily operations in order to maximize safety and clearly communicate new policies. Many of the lessons we've learned can be adopted by other manufacturing businesses as they prepare to reopen.

Tags: Coronavirus, COVID-19, Essential Business

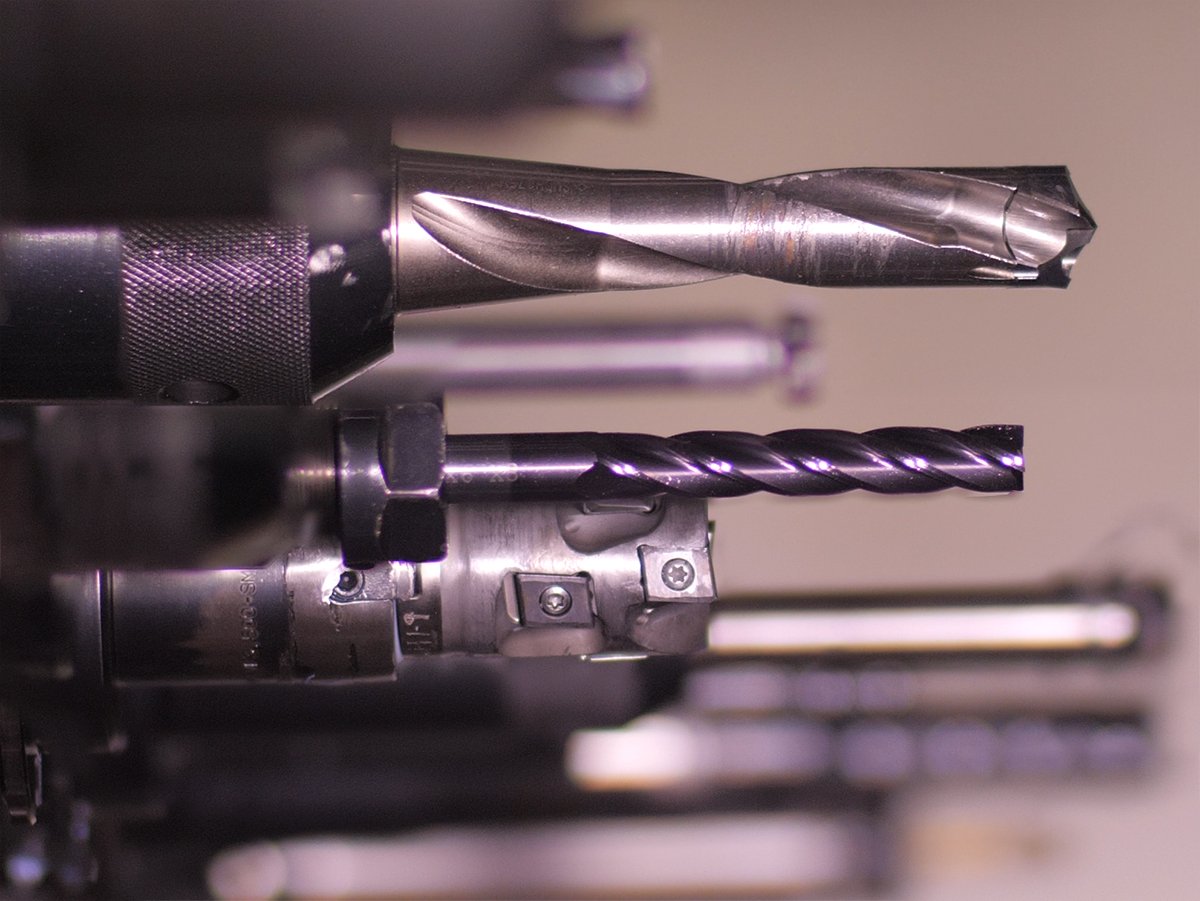

CNC Machining Fixed Costs: Tooling

At the Eagle Group, we provide full-service metalcasting and CNC machining from start to finish. Part of our responsibility as a supplier is to estimate part price for each new product. One of the largest line items affecting final part price on any job is tooling. In metalcasting, tooling often comprises patterns used to create molds and cores. In CNC machining, tooling can refer to work holding fixtures, tool holders, cutting tools or tool inserts.

Tags: CNC Machining, Tooling

The Eagle Group's Response to the COVID-19 Coronavirus

Eagle Alloy, Eagle Precision and Eagle CNC plan to maintain full production capability, even in light of the recent decision by Michigan’s Governor to close all “nonessential” businesses.

Tags: Coronavirus

Metal Properties: Introduction

Metals are all around us, in the things we use to cook, drive, work, and live. When choosing a metal for a cast product or other specific application, it’s important to make sure that its properties will be suitable for the expected operating conditions.

There’s a big difference between the kind of metal used in a skyscraper and the kind of metal used in a gate valve. Some metals are pure elements, like iron (Fe) and aluminum (Al), but most products are made from alloys, or mixtures of metals. Manufacturers must consider many variables before deciding which alloy to use for a particular product.

Tags: Materials, Metals, Metal Properties