Heat Treatment for Cast Products at Eagle Alloy

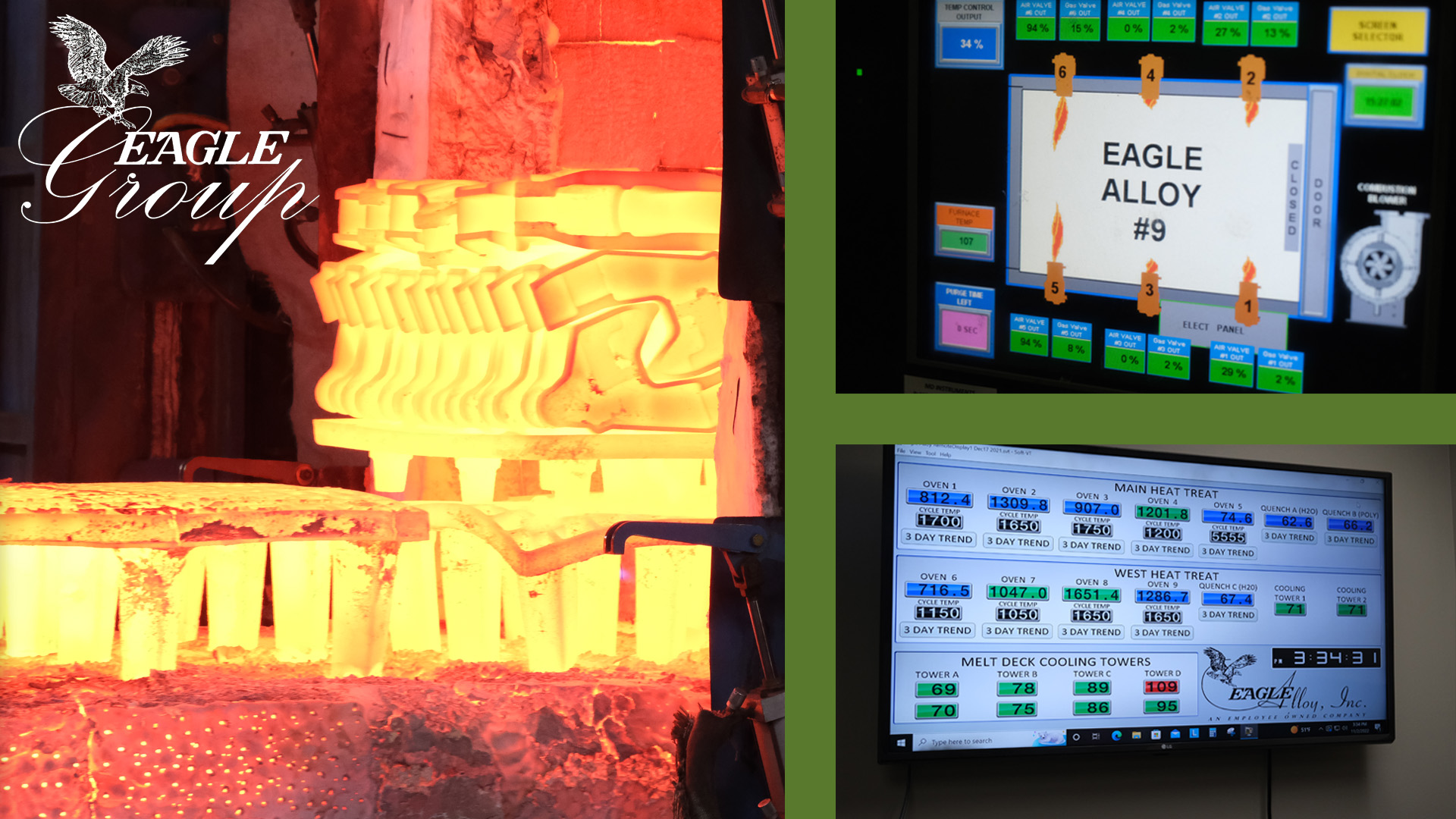

Eagle Alloy provides a wide range of metalcasting services. In addition to casting hundreds of alloy grades that can be formed into virtually any castable shape, our foundry is fully equipped to heat treat the majority of parts we manufacture. In this blog, we’ll be opening the doors to our heat treatment facilities. You’ll get to know what kind of heat treat equipment we utilize to deliver superior products that consistently meet performance expectations.

Casting a part into its required shape does not fully prepare it for a life of service – only heat treatment can ensure a part performs exactly how it should. With the exception of a handful of nickel-based specialty alloys, Eagle Alloy heat treats just about every part that is cast in our facilities. From annealing and normalizing to stress relieving and quenching, we have the furnaces, quench tanks, data and expertise to take a product from inception to delivery.

Tags: Eagle Alloy, Metallurgy, Heat Treatment

Introduction to Heat Treatment for Cast Parts

Metal manufacturers utilize a number of tools to control the mechanical and physical properties of raw materials. An alloy’s chemistry is only one part of the equation: obtaining the final properties can only be achieved through heat treatment. In this introduction, we'll cover the following topics:

- Why heat treatment is important for metalcasting

- Heat treatment for carbon steel vs heat treatment for stainless steel

- The importance of using ASTM standards

- Key heat treatment processes used by foundries and machine shops

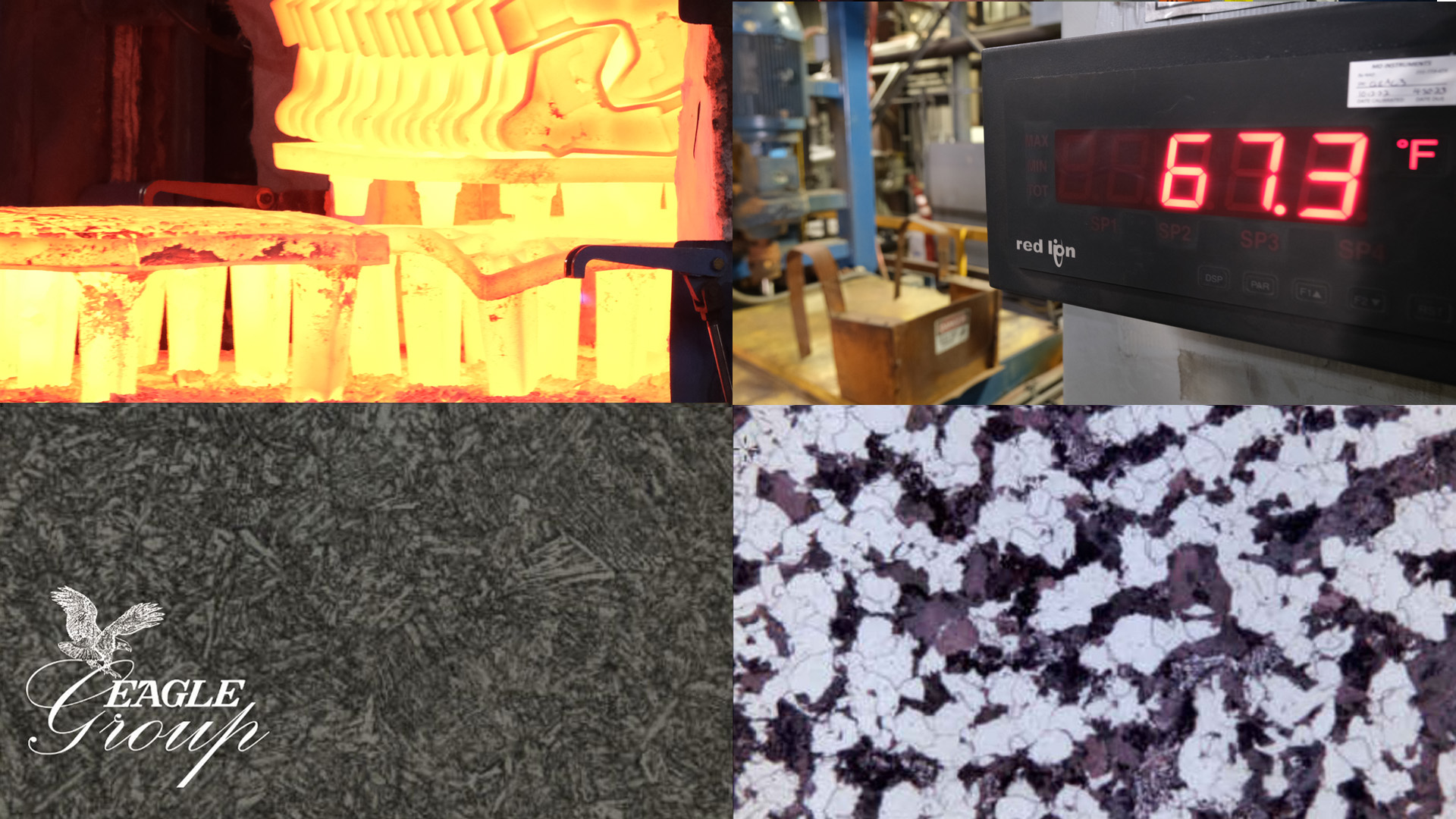

Heat treatment is a broad term describing a range of thermal processes used to control an alloy’s properties. These processes ensure a finished product carries the mechanical and physical properties demanded by its application. Encompassing both heating and cooling, heat treatment incorporates a few distinct and equally important phases:

- Ramp-up: heating the metal;

- Soak: maintaining the metal at a desired temperature for a specified amount of time;

- Cooling: cooling to a specified temperature at a controlled rate and in a controlled environment.

Tags: Metallurgy, Heat Treatment

Robotics in Investment Casting

Our investment casting foundry, Eagle Precision, makes use of robotics in two steps of the casting process. We started with a robotic dipping cell and expanded into two, followed by a third robotic cell that specializes in after-cast grinding. While robotic cells like these do require a large up-front investment, we’re already seeing company-wide benefits resulting from our use of robotics in investment casting.

Robots are becoming more and more common throughout the manufacturing industry, and investment casting is no exception. According to John Scott, VP of Sales at Buntrock Industries, the investment casting industry is seeing increased demand for robotics for three reasons: “lack of workforce availability, desire for increased process control and productivity, and improved health and safety.”

Tags: Investment Casting, Eagle Precision, Robotics, grinding

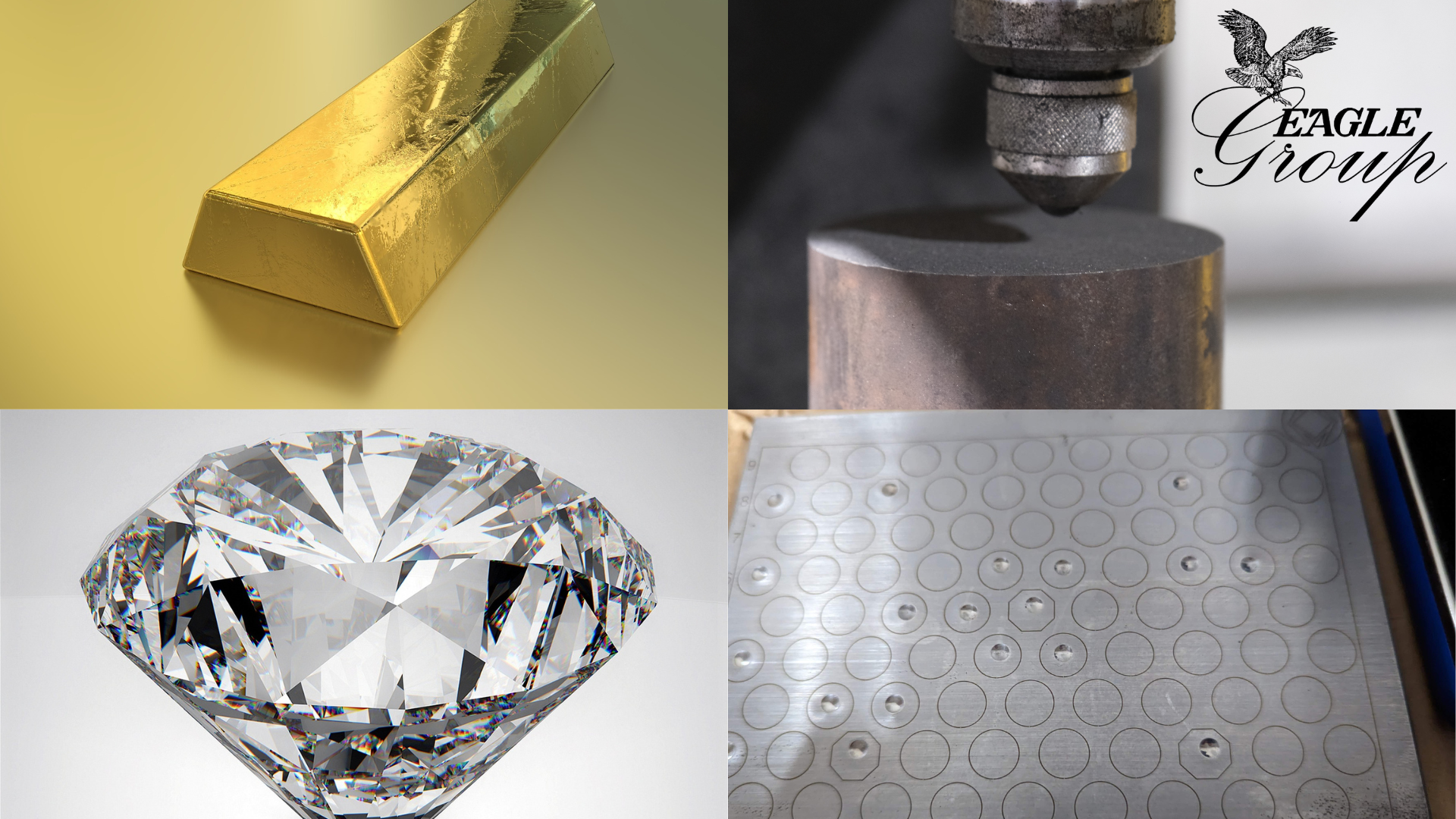

Metal Properties: Hardness

“Hardness” is a concept we use every day to compare objects: fresh bread vs. stale bread, a baseball vs. a softball. In manufacturing the definition is a bit more specific: hardness is a measure of a material’s ability to resist localized scratching or deformation by indentation at a specific loading location.

Our understanding of hardness and relative hardness between materials is key to manufacturing metal products. The correlation of hardness with other mechanical properties also makes it possible for us to predict, with a high degree of accuracy, the strength and ductility of a material without submitting it to destructive testing.

Tags: Metallurgy, Metal Properties, Measurement, Mechanical Properties

Metal Properties: Ductility

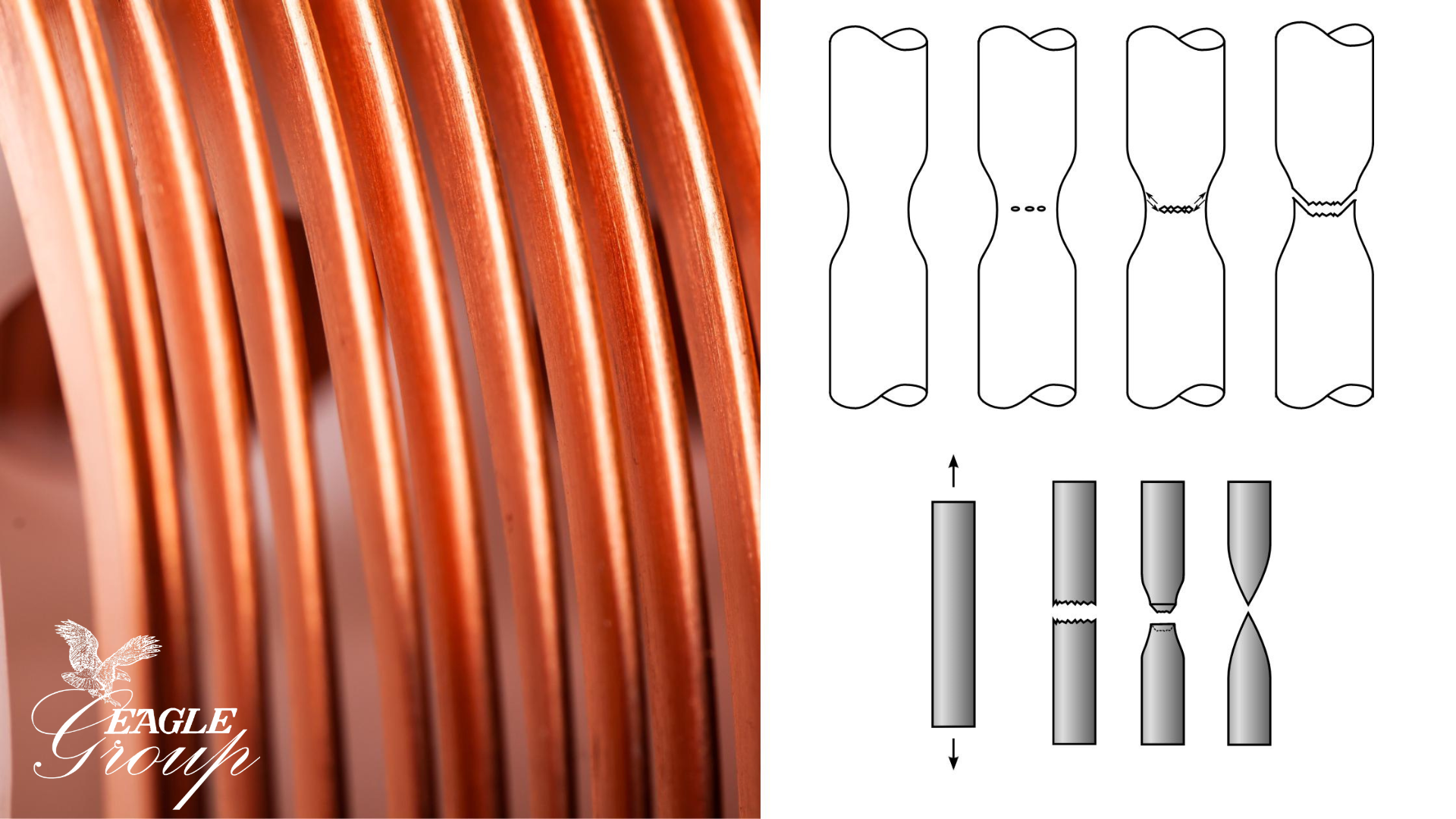

Ductility describes a metal’s amenability to being drawn or stretched without breaking. It is one of the crowning mechanical properties of a metal. Without a sound understanding of the science of ductility, manufacturers would be unable to guarantee the safety of their machinery.

In this blog, we’ll explain why manufacturers rely on ductility to guide them in casting parts that uphold integrity in service while protecting machinery against catastrophic failure.

Metal Properties: Strength

Past civilizations had practical reasons for caring about metal properties. They asked questions like “Can I break my enemy’s sword before he breaks mine?” or “How thick does my armor need to be to provide enough protection?” These warriors had a vested interest in material strength.

Tags: Metals, Metallurgy, Metal Properties, Mechanical Properties

Metal Properties: Conductivity

In previous installments of our series on Metal Properties, we’ve discussed characteristics that set metals apart from one another, as well as those that distinguish them from other nonmetallic elements. Conductivity represents an array of essential features that go to the very heart of what defines a metal. In this article we will be asking: what are the factors affecting the conductivity of metals? What are the most thermally and electrically conductive metals, and why does conductivity matter for manufacturers?

All materials possess some degree of conductivity. One of the main characteristics of metals is their ability to conduct heat and electricity, so metals are all relatively conductive compared to non-metals. However, even within metals you’ll find a broad range in levels of conductivity. A sound knowledge of where various metals fall on the spectrum helps manufacturers choose the right alloy for each product.

Join the Eagle Group at CastExpo 2022

The Eagle Group will participate in CastExpo 2022, celebrating a return to major in-person events. CastExpo is a trade show and congress held every three years that brings together thousands of professionals from the worldwide metalcasting supply chain. This year the event will be held in the Greater Columbus Convention Center April 23-26, 2022.

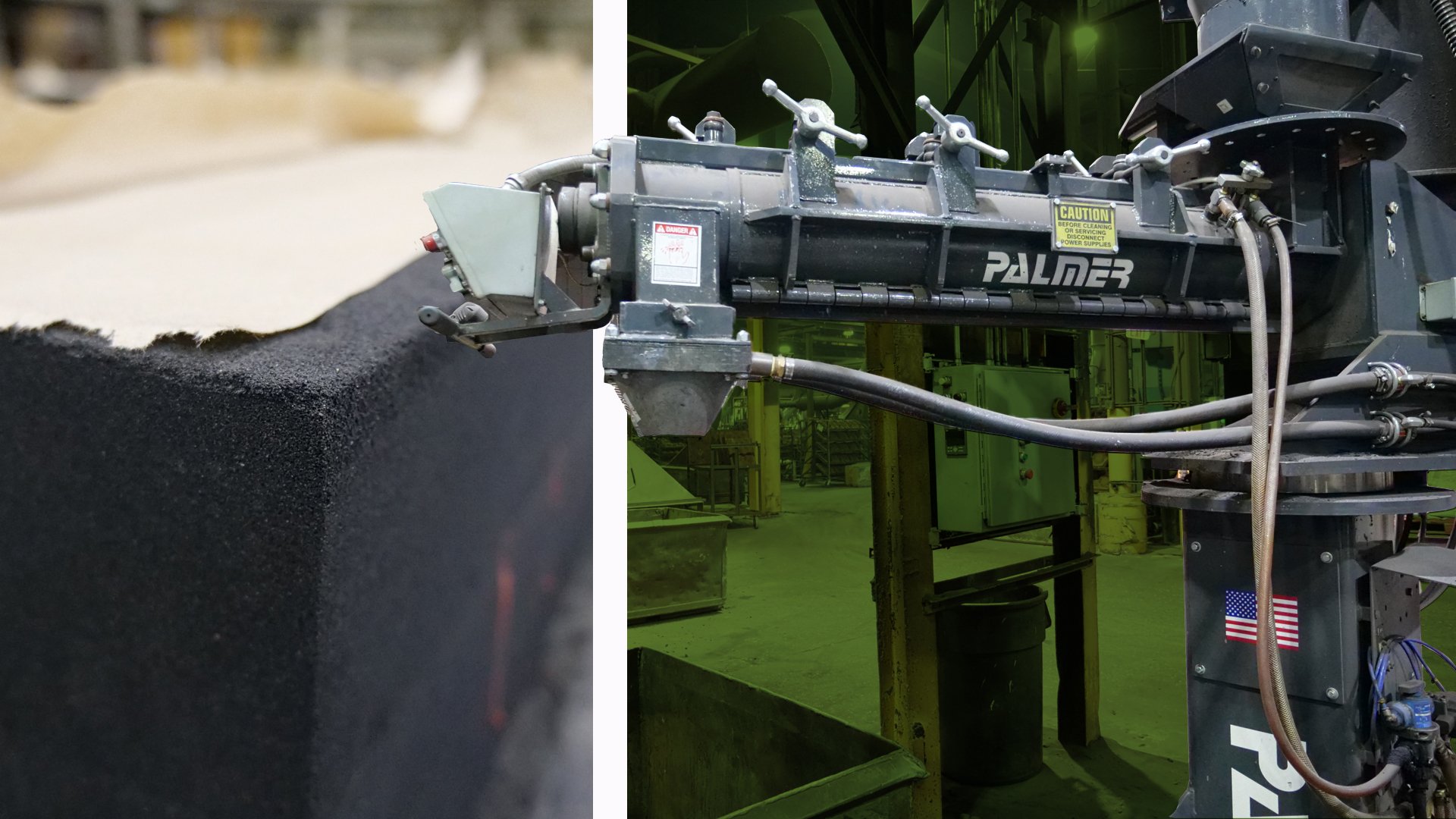

Eagle Alloy Upgrades Casting Facilities with New Airset Sand Mixer

The Eagle Group produces a wide variety of cast and machined products for many industries. One of our strengths as a company is our ability to employ different casting processes. Eagle Precision Cast Parts, for example, specializes in investment casting, and Eagle Alloy specializes in shell molding. When you tour the shop floor at Eagle Alloy, you’ll see our shell molding machines busy at work, turning out most of our order flow. But that’s not all we do: Eagle Alloy also houses a robust airset (no-bake) molding line to support our shell customers.

Tags: Eagle Alloy, Airset Casting, Facilities, Equipment

On-site Coaching Helps Eagle Employees Succeed

At the Eagle Group we believe in our employees. We know the success of our companies depends on the people doing the work, day to day, to design and produce our award-winning cast parts. We also acknowledge that our employees have lives outside the workplace, and external challenges play a major role in everyone's ability to grow and succeed on the job.

That's why all Eagle Group companies partner with the Employer Resource Network® to provide personal, on-site success coaching to all of our employees. Our trained social worker takes on issues across the board, from loan applications and housing to therapy and medical care.

Tags: Education, Employment, Benefits