5 Mistakes Companies Make When Choosing a New Metalcasting Supplier

Whether you're bringing a new product to market, improving on an old design or entering the world of metal manufacturing for the first time, you'll need to find the right foundry for the job. Choosing a metal casting supplier can be a daunting task, and not everyone makes the right choice the first time.

These five mistakes companies make when choosing a new metal casting supplier can lead to expensive fixes, defective products, overpriced castings, logistical headaches and customer service nightmares. Read on to find out what NOT to do when choosing a new foundry.

Tags: Metalcasting, Supply chain, Suppliers

Introduction to CNC Machining

This article was updated on July 8, 2025.

CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again.

Tags: Machining, CNC Machining, Eagle CNC

Case Study: Lean Manufacturing at Eagle Alloy

Eagle Alloy, Inc. was founded in 1979 and quickly grew from a short-run facility to a medium-to-high-production steel foundry. Despite the company’s success, its founders were not satisfied with the status quo. Having heard of developments in lean manufacturing, they decided to implement these tools in hopes of achieving greater efficiency, stability and quality throughout the production process.

5S: The Beginning

As with many production facilities beginning to experiment with lean manufacturing, Eagle Alloy started with 5S. 5S is easy to adapt to just about any environment, and the key to lean is customization. Every lean tool must be adapted to the particular type of production, to the size of the company and to the facility's space.

Tags: Lean Manufacturing, Eagle Alloy, Case Study

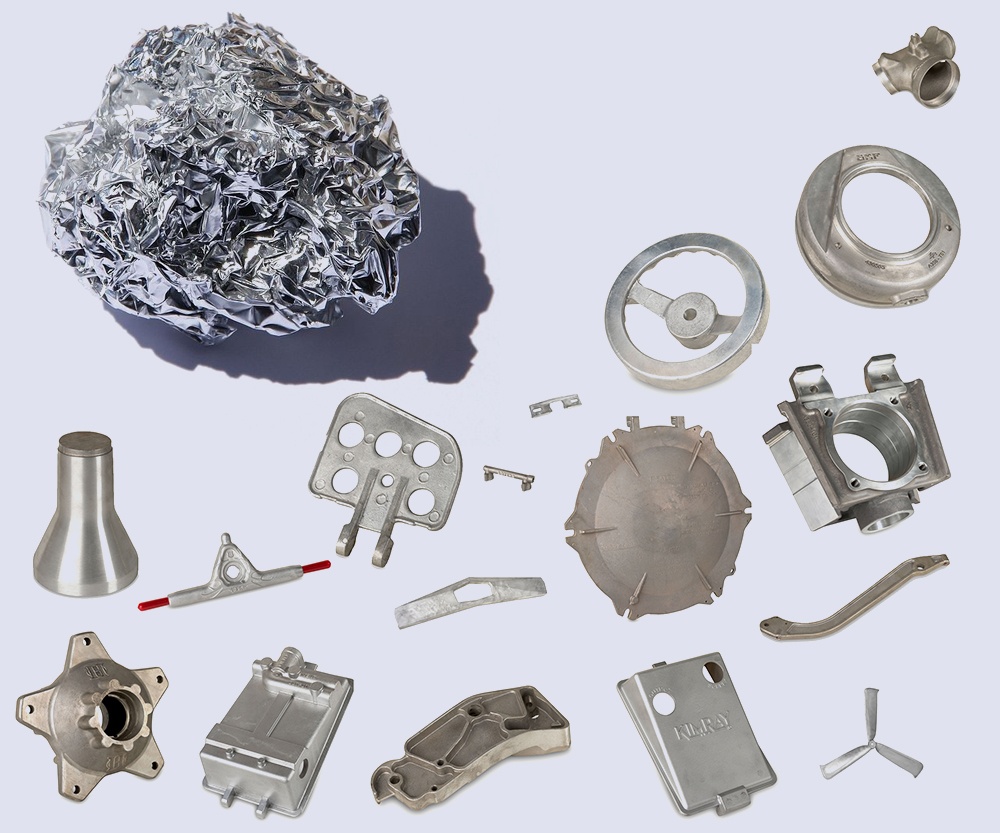

Casting Aluminum: Comparison of Methods

Aluminum can be shaped through a wide variety of process, including:

- Casting

- Extrusion

- Forging

- Rolling

For any type of metal, casting is arguably the most versatile of all of the forming processes, and results in the greatest variety of parts. In fact, the US Department of Energy estimates that over 90% of all manufactured goods contain metal cast products.

The same casting techniques used for other metals can be applied to aluminum, but some of the most popular methods used with aluminum are permanent mold casting, greensand casting and die casting.

Tags: Metalcasting, Processes, Aluminum Casting, Aluminum, Eagle Aluminum

Numbers Don't Lie: Eagle Companies Achieve Huge Improvements in 2017

Two Eagle Group companies, Eagle Alloy, Inc., and Eagle CNC Technologies, Inc., have posted a series of personal bests and significant improvements across the board.

As you can see below, Eagle Alloy's achievements in 2017 include:

- 96.4% delivery – 2nd best in company history

- 1.87% scrap – BEST in company history

- 2.64% returns – Best in last 10 years

- 97.4% audit score – Best in last 8 years

- .27 PPM resulting in complaints – BEST in company history

Tags: Eagle Alloy, Efficiency, Eagle CNC

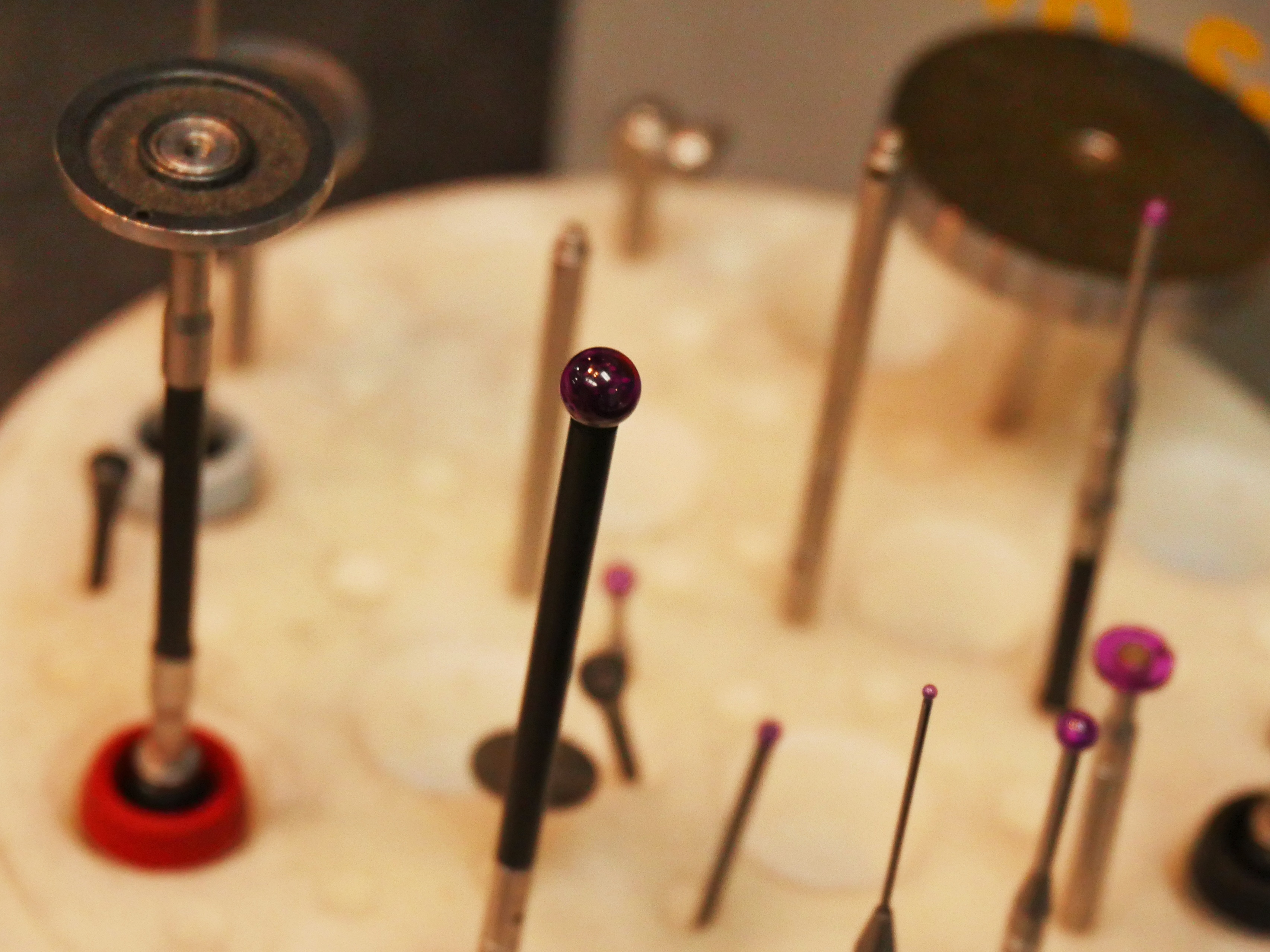

CNC Metrology: What Can a CMM Measure?

Coordinate Measuring Machines, known more often as CMMs, are a staple of industrial metrology. Of the thousands of variations of CMMs, you're likely to encounter at least one version in every manufacturing quality control department. You might not recognize it at first because CMMs can look like, well, pretty much anything–but in any form, these hard-working machines allow manufacturers to accurately measure a long list of product characteristics.

Sure, manufacturers could still measure their products the old fashioned way–with a good set of calipers and a lot of trigonometry–but in today's competitive environment, we need to take measurements in minutes, not days. We also require superior accuracy, sometimes down to .00005".

Tags: CNC Machining, Metrology

New Eagle Group Resource Introduces Aluminum to Manufacturers

Eagle Aluminum Cast Products, Inc. recently published an ebook offering insight into manufacturing with aluminum.

Manufacturing with Aluminum: History, Forming Techniques and Best Practices draws on decades of experience, taking a holistic approach to aluminum manufacturing. Weighing in at just under 25 illustrated pages, the ebook aims to fill a gap between online resources and textbooks. According to Jim Smith, Technical Manager at Eagle Aluminum, “We want to make sure anyone curious about aluminum can get all the basic information they need, without searching all over the Internet or going back to school.”

Tags: Manufacturing, Aluminum Casting, Aluminum, Eagle Aluminum, Press Release, News

Join the Eagle Group at the Design2Part Show

The Eagle Group will be at Design2Part 2018 in Grapevine, TX, March 14-15. If you're in the area or interested in going, we can get you in the door for free!

The event will be the largest contract manufacturing trade show in the region, with over 300 categories of manufacturing services on display. Design2Part is the place to be if you want to:

- Find quality suppliers

- Discover new technologies

- Solve manufacturing problems

Tags: Insider, Design2Part, Trade Show

Aluminum Casting in Practice: A Case Study of Cast Aluminum Fan Blades

A major manufacturer of ventilation systems contacted Eagle Aluminum Cast Products, Inc. when demand was growing and they were ready to make a change.

The customer had already been producing 48” fan blades for agricultural use through green sand casting, but they’d outgrown that method. Demand projections suggested that permanent mold casting would yield lower per-part costs, with the added benefit of greater consistency.

Years later, EACP still produces fan blades for the customer through the process of permanent mold casting. Demand has increased even more, and product offerings have become more diverse. Read on to learn how EACP handles the design, production and delivery of this cast aluminum fan blade.

Tags: Aluminum Casting, Aluminum, All About Al, Case Study, Eagle Aluminum

Branding and Social Media for Manufacturers

Originally posted in the American Foundry Society's Modern Casting Blog

Erik Deckers, a marketing speaker at this year’s Metalcasting Congress, has co-authored a book with Kyle Lacy, Branding Yourself: How to Use Social Media to Invent or Reinvent Yourself, third edition.

The book is a guide to the major social media platforms, and how you take charge of your brand on those platforms.

We need to listen to Deckers’ expertise. He knows how you can make these social media platforms work for you, and he can help you decide which ones will be the best for you.

Tags: Marketing, Digital Marketing, Branding