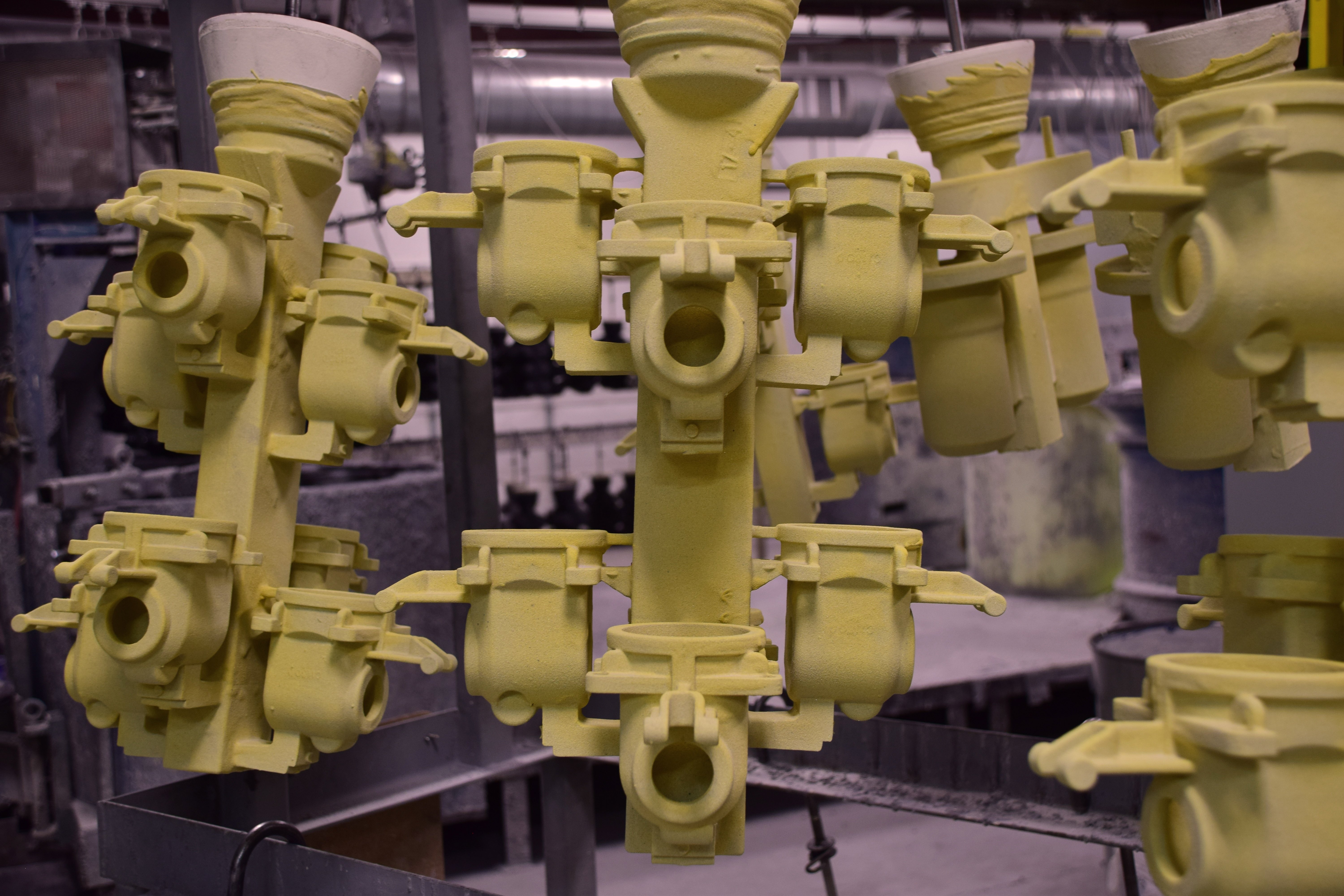

How the Investment Casting Process Works

Investment casting, sometimes known as lost-wax casting, is a metal forming method known for its ability to produce parts with tight tolerances, complex inner cavities and accurate dimensions.

As we discussed in our Introduction to Investment Casting post, the basic technique has existed for millennia. Over the years, innovations in equipment and methodology have kept pace with demand. Today, investment casting is one of the most popular forms of metal casting.

Read on to learn more about the unique process of investment casting.

Tags: Metalcasting, Processes, Investment Casting, Eagle Precision

5 Lean Manufacturing Tools You Should Already Be Using

Lean Manufacturing principles encourage maximum efficiency for just about any production facility. Lean Manufacturing is also more of a necessity than ever, with cutthroat competition across the manufacturing industry forcing all players to up their efficiency levels.

If you're worried that your company isn't lean enough, take a look at these five tools from the Lean Manufacturing playbook.

Tags: Lean Manufacturing, Manufacturing, Efficiency, Productivity

Introduction to Investment Casting

Investment casting is nearly as old as metalcasting itself, with the earliest known examples dating back to 3,500 BC. Before investment casting was invented, metal castings were created using open stone or ceramic molds. Investment casting allowed for much greater detail and smoother finish, vastly expanding the possibilities of metal casting.

Today, investment casting is one of the most versatile methods of metal casting. The process, which is still similar to that used over 5,000 years ago, allows for tighter tolerances, more intricate shapes and smoother surface finishes than other metal casting methods.

Tags: Metalcasting, Processes, Investment Casting, History

What Is Lean Manufacturing?

Lean manufacturing helps manufacturers improve efficiency by eliminating waste in the production process, but what exactly is lean manufacturing? Is it a product, a procedure, a religion?

None of the above. Lean manufacturing is an adaptable set of “tools” that can be applied to any system of manufacturing–whether that system produces spring coils, jet engines or blog posts. It starts with identifying waste in a production process, and then focuses on eliminating that waste bit by bit until production is as streamlined and efficient as possible.

Measuring Standards: From Pharaohs' Forearms to the Speed of Light

Modern manufacturing wouldn't be possible without rigorous standards of measurement, along with sophisticated tools and techniques to help us measure tools, workpieces and finished products.

CNC machining is a prime example of the practical uses of modern measuring, or metrology. In metal-based manufacturing, CNC machining is often the last process before a part is delivered. Without incredibly accurate and precise ways to measure and cut, many of the metal products we take for granted would be impossible to produce.

The history of measurement is the story of how human civilization strove to find new ways to measure accurately, and it all leads up to modern metrology.

Tags: Machining, CNC Machining, Metrology, History

All About Al: Choosing the Right Aluminum Alloy

In manufacturing, aluminum is rarely pure. Instead, manufacturers form alloys that dramatically increase aluminum’s strength and stiffness, while maintaining its other desirable properties. Both professionals and non-professionals often make comparisons between aluminum and steel, because the two metals are both used for such a wide variety of products.

But comparing aluminum to steel is a bit like comparing apples to oranges: steel is already an alloy, while aluminum is an element. Carbon steel, a basic steel alloy, is composed of iron (Fe) and carbon (C). Pure aluminum, despite its many winning properties, is too soft and not strong enough for most industrial applications. But aluminum alloys can be thirty times stronger than pure aluminum, and regularly exceed steel in strength-to-weight ratios.

Tags: Processes, Aluminum Casting, Aluminum, All About Al, Metals

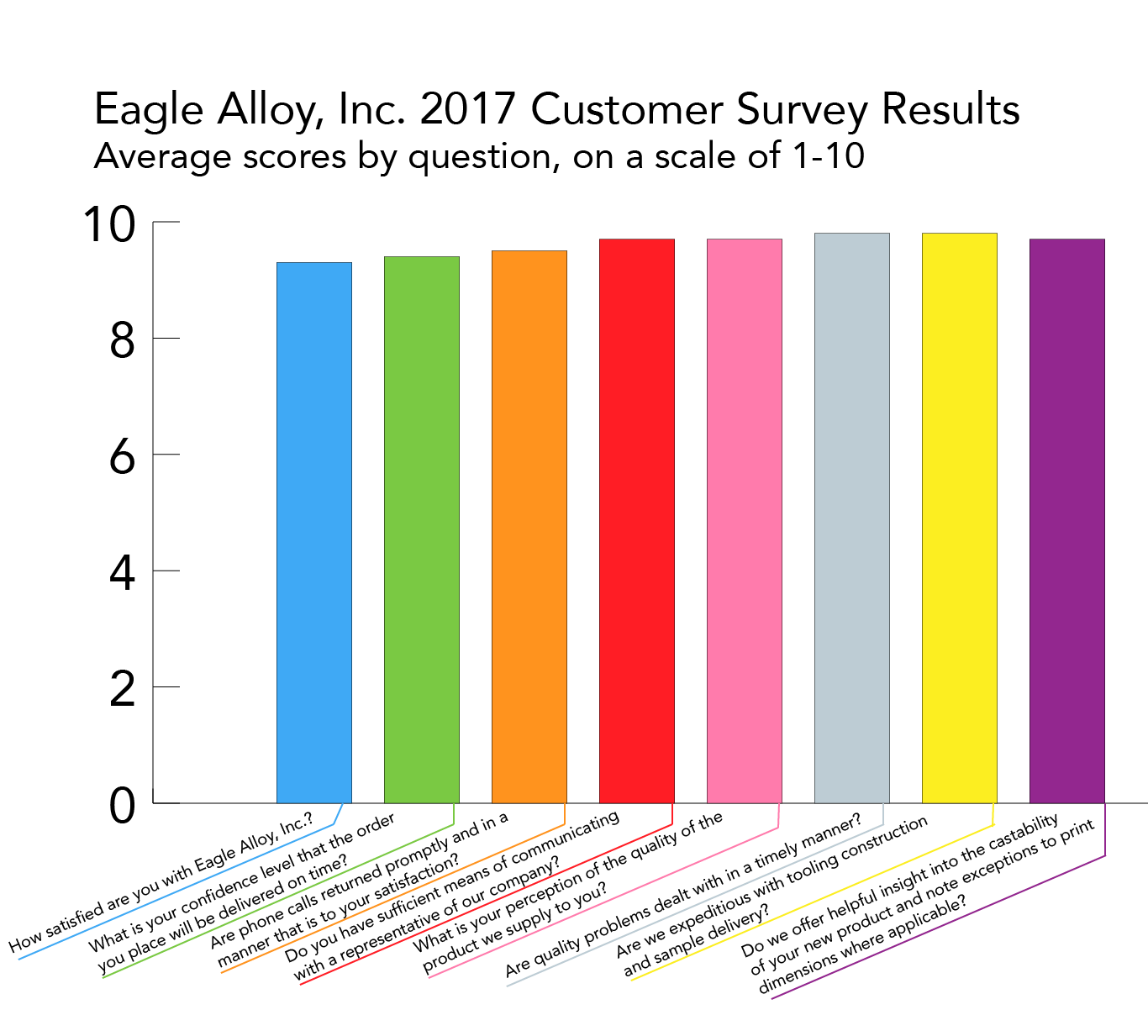

Excellent Marks for Eagle Alloy, Inc.

Eagle Alloy, Inc. provided customers with its annual quality survey, and received excellent ratings for 2017.

On behalf of Eagle Alloy, we'd like to thank our customers for taking the time to fill out this survey, and we look forward to continued collaboration in 2018!

Tags: Customer satisfaction, Testimonials, Eagle Group Values, Customer survey, Business Philosphy

The ABCs of ISO: Why Certifications Matter

Whether your businesses is considering a new certification or you're shopping for a new supplier, it's important to know exactly what certifications can offer.

Here, we focus on the quality-based ISO 9001 standards. Over 1 million companies in over 170 countries meet ISO 9001 standards, but there are millions more that don't.

Read on to learn the difference between those that are certified...and those that aren't.

Tags: ISO Certification, Certification, Compliance

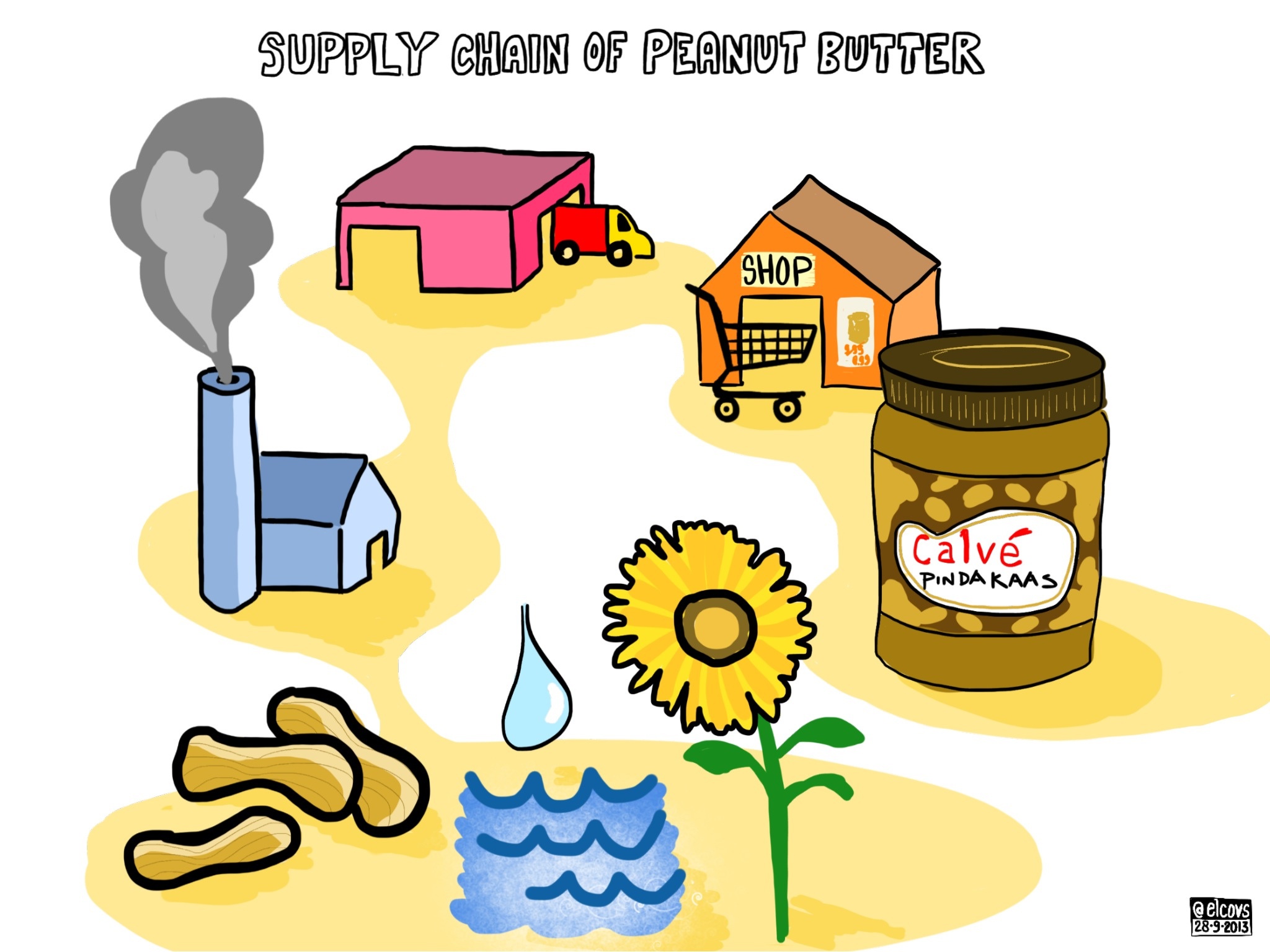

Understanding Your Supply Chain

Supply Chain Management (SCM) is becoming more and more important in the manufacturing industry. Businesses around the world are taking a more active approach to supply chain management, resulting in smoother process integration, higher profits and more transparency.

Your supply chain is much more than just where your business sources raw materials, parts or other inputs. It's a long list of interactions, starting before raw material is even removed from the ground, and ending only when the end customer has a product in hand.

If your business is ignoring the supply chain, you could be left in the dark when it comes to supply chain disruptions, leading to unexpected losses.

9 Ways to Improve Manufacturing Efficiency

This article was updated on July 10, 2025.

Efficiency is good for any business. It doesn’t matter if your company is manufacturing or service oriented. Greater process efficiency always offers a wide range of benefits over "business as usual."

On a broad level, manufacturing more efficiently can help cut costs, improve throughput and reduce environmental impact. All of these general benefits lead to additional benefits down the road, from increased sales and quality to improved company image.

Read on for 9 ideas to improve manufacturing efficiency.

Tags: Lean Manufacturing, Processes, Manufacturing, Efficiency