Case Study: Reverse Engineering Cast Products on an Expedited Timeline

Cem-Tec, a manufacturer of steel light poles in business since 1974, approached Eagle Alloy, Inc. with an emergency order. Due to an unforeseen supply-chain issue, they needed to find a new foundry to manufacture one of their popular products. With orders in and customers waiting, the clock was already ticking.

The following case study illustrates the steps Eagle Alloy followed to transfer casting of the product to our facility and to ensure that Cem-Tec had high-quality products ready for their customers as soon as possible.

The Redesign Process

At Eagle Alloy, an expedited timeline doesn’t mean we skip any steps. We still perform a detailed APQP analysis, make aesthetic and structural improvements to the design, conduct a company-wide review of manufacturing plans and rigorously test a sample batch.

Cem-Tec was able to provide us with CAD files, blueprints and tooling from the original supplier, along with physical samples of the part. We then interfaced with their team through a number of virtual meetings to obtain necessary information for our APQP report. In addition to the shape and the function of the part, we learned that it will be constantly exposed to the elements, and must be durable enough to last through years of wind, rain and snow.

Since the original version was aesthetically and functionally adequate, we didn’t want to design the entire product from the beginning. Instead, we reverse engineered a new (and improved) version and made changes only where necessary.

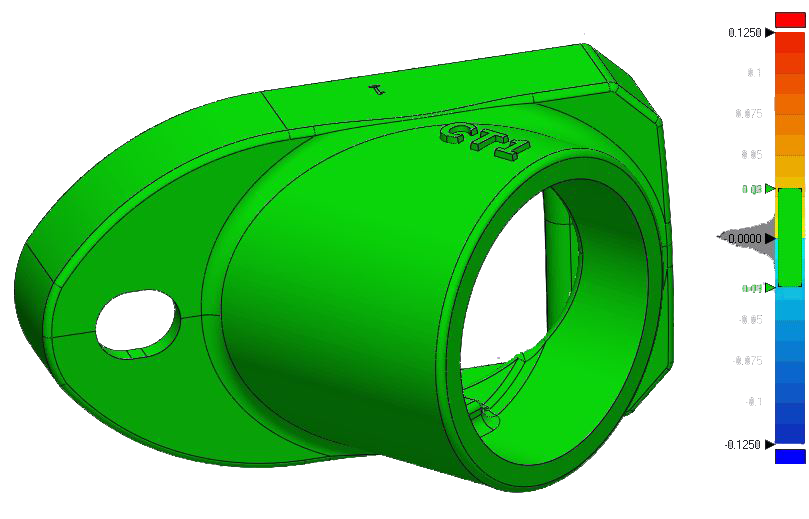

We started by using a handheld laser scanner to evaluate the tolerance conformity and surface quality of the previous supplier’s parts. We then imported the CAD files and evaluated the blueprints. Based on data from our laser scanner, prior experience and software models, we made several adjustments. Some of our changes improved the part’s appearance, while others made the part stronger and more repeatable for manufacturing.

Download full case study to learn more:

Download full case study to learn more:

- Software Eagle Alloy used to finalize design

- Solidification simulation to save time and money on tooling redesign

- Where 3D printing fits into the design process

- Unique sampling strategy for expedited timeline

- What we changed in the product and the tooling

Tags: Eagle Alloy, Case Study, Product Design, Development, Product Development

Written by Jeff Cook

Jeff Cook is Chief Sales and Marketing Officer for Eagle Alloy in Muskegon, MI. While enlisted in the Marine Corps Reserves, he began working at Eagle Alloy in 1986 as a snag grinder on 3rd shift after his father told him to “Get a job!” Jeff is past President of the American Foundry Society. His passions include educating young people on the careers and advancement available in the metalcasting industry.