What Precision Machine Shops Do: Broaching

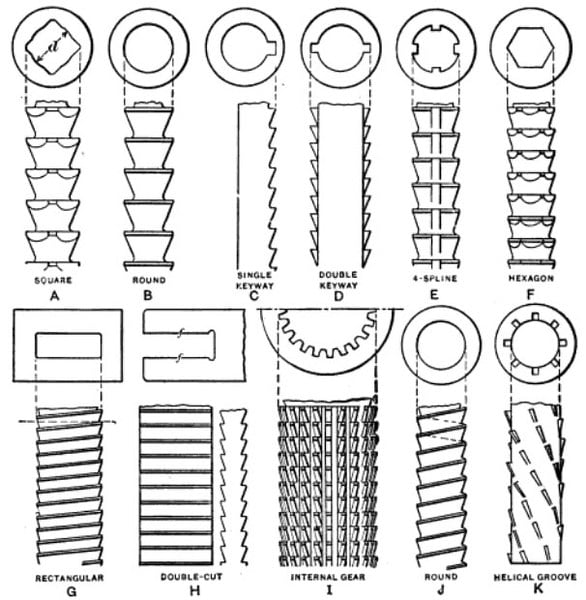

Broaching is a machining process using a cutting tool with teeth that increase in size from front to back. In many cases, an entire surface (or multiple surfaces) can be finished in a single pass with broaching. The technique is most often applied to finish holes, splines and flat surfaces.

Broaching is a relatively new machining process, developed in the 1850s with metal-specific applications. Originally, broaching was used to perform work on internal characteristics, like keyholes in pulleys and gears. During the 20th century, broaching was further developed for use in firearms, and subsequent developments have dramatically improved tolerances and made broaching more versatile for modern machine shops.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do, broaching

Casting Advocates: Get to Know AFS

In our blog series, Casting Advocates, we get to know organizations and industry leaders who work to elevate the metalcasting profession. This installment focuses on the American Foundry Society (AFS).

The American Foundry Society is a national organization with a mission to "advance the success of its members and the metal casting industry through advocacy, education and innovation." In support of this mission, AFS works constantly to support technical innovation, advocate for beneficial policies, promote positive perception of the industry, develop workforce skills and provide a range of services and networking opportunities for casting facilities.

Tags: Education, Community, Casting Advocates, Trade Associations

What Precision Machine Shops Do: Sawing

Sawing is one of the oldest cutting techniques in use today, and innovations have allowed the process to keep up with advances in material, tolerances and product complexity. By definition, sawing is cutting a narrow slit in a workpiece by moving a toothed or abrasive cutting tool against the surface. Sawing is often used to remove large sections of material without particular concern for tolerances, but modern CNC sawing machines can be used for finishing work as well.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

5 Ways to Tell if Casting Is the Right Manufacturing Process for Your Products

Modern metal manufacturing offers a wide range of choices to bring designs into reality. Metalcasting has been around for millennia, and it's undergone its fair share of innovation over the years. Casting facilities can now handle almost any alloy, and can cast intricate designs with complex inner cavities that wouldn't have been possible even a few decades ago.

Tags: Metalcasting, Manufacturing, Fabrication to Casting, Fab-Casting

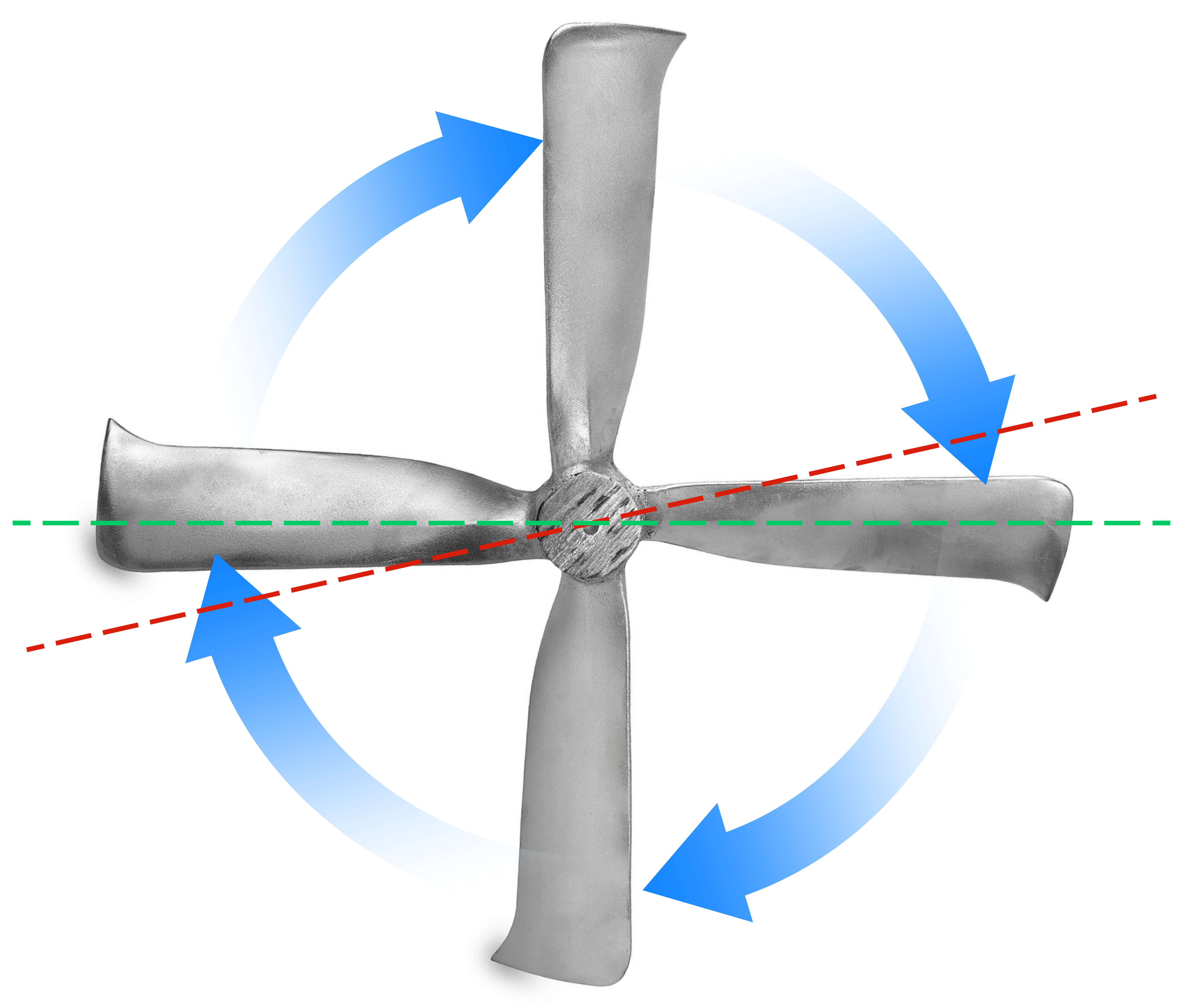

Finding the Perfect Balance: Case Study of Continuous Improvement in Cast Aluminum Fan Propeller Inspection

Eagle Aluminum specializes in permanent molding and greensand casting of aluminum products. In keeping with the Eagle Group's philosophy of continuous improvement, Eagle Aluminum's team is always looking for ways to improve our processes to achieve better quality, greater efficiency and reduced returns. This case study focuses on a recent innovation that dramatically improved the return rate for a line of parts without adding to processing time.

CAST IN STEEL: Student Teams Compete to Cast the Best Steel Viking Axe

This year the Steel Founders' Society of America (SFSA) introduced a national competition to engage students with steel casting and help foundries connect with the next generation of manufacturing professionals. Inspired by History Channel's Forged in Fire, the Cast in Steel competition brings teams of engineering students from around the country together to find out who can cast the best Viking axe. Testing, judging and awards took place prior to CastExpo in Atlanta, GA.

Tags: Investment Casting, Eagle Precision, Airset Casting, Event, Student Metalcasting Competition, CastExpo, Trade Associations

Casting Advocates: Get to Know FAM

In our blog series, Casting Advocates, we get to know organizations and industry leaders who work to elevate the metalcasting profession. This installment focuses on the Foundry Association of Michigan.

The Foundry Association of Michigan (FAM) is a non-profit organization that works between the Michigan casting industry and state legislators, acting as a liaison and a lobbyist. When Michigan legislators propose new bills that will affect the casting community, either negatively or positively, FAM is there to galvanize member firms around an appropriate response, with the goal of keeping Michigan casting competitive locally and worldwide.

Tags: Education, Community, Casting Advocates, Trade Associations

Join the Eagle Group at Design-2-Part in Santa Clara, CA

The Eagle Group will be at Design-2-Part 2019 in Santa Clara, CA, May 22 and 23. We hope you can join us at the show!

At Design-2-Part, you'll find over 300 categories of manufacturing services on display. The show is designed to help manufacturers find quality suppliers, discover new technologies and solve manufacturing problems. Design-2-Part attendees love the hands-on aspect of the show, with so many suppliers available to answer questions and help turn ideas into reality.

The Eagle Group will hold a booth for both days of the show, with representatives of all four of our companies in attendance. We'd be happy to meet and discuss any of your questions and concerns in person. Design-2-Part is a great environment to learn more about new processes, materials and practices in the manufacturing industry.

Tags: Insider, Design2Part, Trade Show

Casting Advocates: Get to Know SFSA

In our blog series, Casting Advocates, we explore the work of organizations and industry leaders who work to elevate the metalcasting profession. Here in this first installment, we focus on the Steel Founders' Society of America.

The Steel Founders' Society of America (SFSA) was first organized in 1902, and initial meetings were a "luncheon club" attended by a handful of casting companies from the Midwest and the East Coast. After more than a century of evolution, SFSA is now a major force in promoting metalcasting competitiveness industry-wide. Today, SFSA works to provide members with the tools and knowledge to succeed in today's high-tech manufacturing environment.

Tags: Education, Community, Casting Advocates, Trade Associations

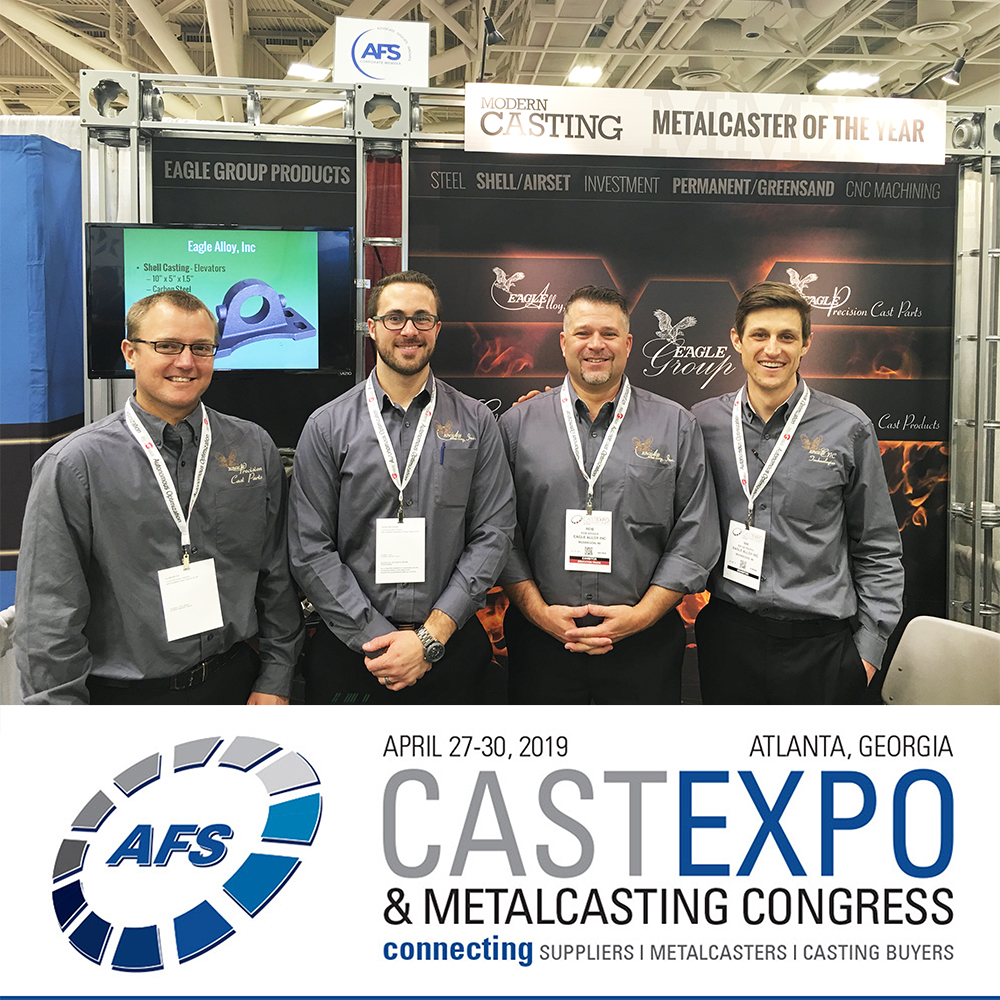

Join the Eagle Group at CastExpo 2019

The 2019 American Foundry Society CastExpo & Metalcasting Congress is coming up at the end of April, and we hope you can join us in Atlanta for the event. Representatives from all Eagle Group companies will be in attendance, ready to provide expertise in metalcasting, machining, product development and inspection.

Stop by our booth (#424) and speak to our sales or engineering teams regarding the capabilities of the various Eagle Group of companies. Learn the benefits of and the differences between our shell and investment processes, as well as the many fine components made in our aluminum foundry. Our machining capabilities will also be on display.