All About Al: Aluminum's Winning Properties

Recently in our All About Al blog series we discussed aluminum's history and origins. Now we're getting deeper into why aluminum is the perfect material for manufacturing such a wide range of products.

Aluminum owes its versatility in manufacturing to a unique set of properties. These include:

- Low melting temperature

- Excellent malleability

- Light weight

- Corrosion resistance

Tags: Aluminum Casting, Aluminum, Materials, All About Al

Foundry in a Box: Bringing Metalcasting to the Classroom

Ask a group of 5th graders what they want to be when they grow up, and you'll get a long list of answers: firefighter, detective, athlete, musician, astronaut. These (and other top kids' dream jobs) are certainly vital to our society, but as proud and forward-thinking manufacturers, we have to ask: Wouldn't you rather be a metal caster, or a machinist, or a Six Sigma coach?

Maybe the answer is "yes," but the issue is that not many kids have been asked this question. That's where programs like Foundry in a Box come in. Dedicated professionals in the manufacturing industry visit schools and introduce students to the basics of metalcasting, and manufacturing careers, through hands-on projects. Programs like this not only expand students' horizons, but they're also vital to the future of manufacturing in the United States.

Tags: Metalcasting, Foundry in a Box, Education

How Shell Molding Compares to Other Metalcasting Methods

The shell mold process is unique and exhibits many advantages over other metal casting processes, but many people don’t fully understand its benefits.

In this installment of the Introduction to Shell Molding blog series, we will compare and contrast the shell mold process with investment casting and greensand casting methods. It is important to keep in mind that all processes have their own appropriate applications.

Based on your part's needs in terms of tolerances, production volume and surface finish, any one of these processes could be the ideal match.

Tags: Shell Molding, Metalcasting, Processes, Introduction to Shell Molding

How To Tell if Casting Is Right for Your Products

Our recent post on fabrication to casting conversion might have gotten your wheels turning. Now you're wondering, "Could my products benefit by making the switch to casting?"

If you sell, use or otherwise produce fabricated parts, there's a good chance that you could produce them better, cheaper and faster through casting. To help you decide, we've prepared a brief Part Evaluation survey.

Tags: Metalcasting, Processes, Fabrication to Casting, Fab-Casting

7 Essential Metrology Tools for Modern CNC Machine Shops

Metrology is the science of measurement. In CNC machining, principles of metrology need to be applied throughout the production process to ensure that each part is machined to the right size and shape, in accordance with specified tolerances.

It’s simple enough to take a ruler or a measuring tape and mark out inches or millimeters. But measuring dimensions of CNC machined parts – many with tolerances tighter than +/- .001 inch – is a whole other ball game. When you’re dealing with measurements that small, you need to have sophisticated measuring tools, and the knowledge to use them.

Tags: Machining, CNC Machining, Metrology

All About Al: Crash Course in Aluminum History

Aluminum is the third most common element on our planet. It’s by far the most abundant metal, and it’s also one of the most versatile.

Aluminum is light, strong, flexible and corrosion resistant. It can also be shaped relatively easily, in both a solid and molten state, and can be stamped to widths thinner than the human hair.

You’ll find aluminum in everything from buildings to cars, from Pepsi cans to laptops, and from power lines to bullet trains. But where does this one-of-a-kind metal come from, and how did it get to be so widely used?

Tags: Metalcasting, Aluminum Casting, Aluminum, Materials, All About Al

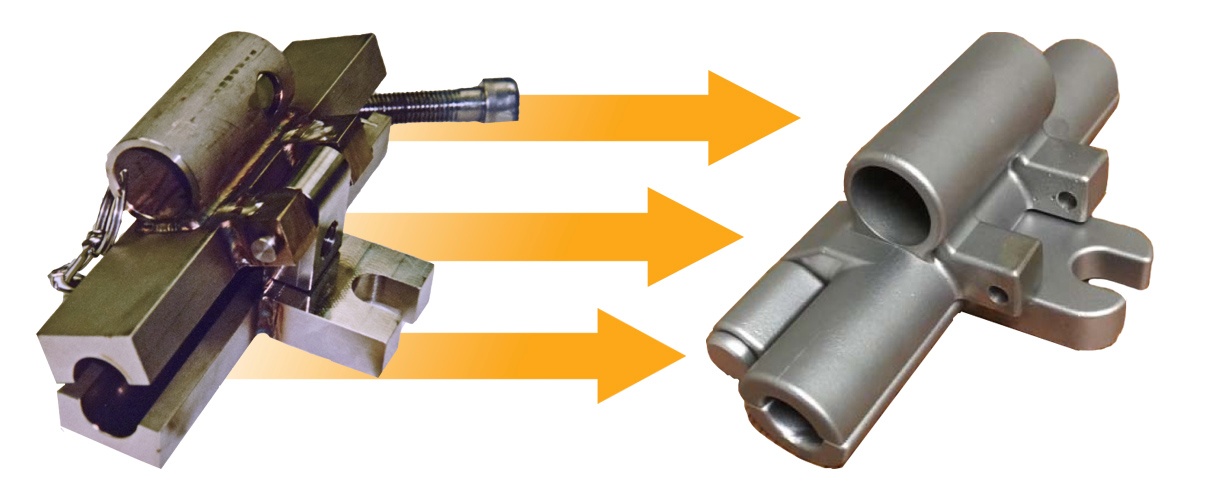

One Part's Journey from Fabrication to Casting

It all started on a routine facility tour

While touring a client’s facility, representatives of Eagle Precision Cast Products noticed a cable clamp assembly–a relatively complex fabricated part that they believed would be an excellent candidate for fabrication to casting conversion.

Tags: Metalcasting, Processes, Fabrication to Casting, Fabrication, Fab-Casting, Investment Casting, Case Study

3 Ways Lean Manufacturing Lowers Casting Costs

Looking to lower the cost of your casting purchases? The key is to find a foundry that incorporates lean manufacturing principles into the process. These three principles can be applied to manufacturing castings, driving down costs significantly:

- Castability

- Bottleneck Solutions

- Optimizing Cycle Time

Tags: Lean Manufacturing, Metalcasting, Buyer's Guide, Purchasing Cast Products

8 Key Metals Used in Casting

We're here to talk about METAL

No, not that kind of metal–actual metal, like the kind that your car is made out of, that replaced your uncle's bad knee, that holds up the skyscrapers downtown, that keeps cruise ships afloat, that built the rocket that catapulted the telecom satellite into space so you can have an internet connection, that makes up that satellite...

A lot of things are made out of metal. You get the idea.

Tags: Materials, Metals, Metal Properties

3 Quick Tips for Buying Cast Parts

Whether you're looking to produce a new product or save money on products you're already manufacturing, cast parts can be a great option. Metalcasting has been around for over 5,000 years, and today's processes, along with cnc machining, can produce just about any part imaginable.

Tags: Metalcasting, Machining, Buyer's Guide, Tips