Getting Started with Airset Casting

Every manufacturer bringing a cast product to market must decide on the right casting process to use. Casting methods like shell molding, greensand casting, investment casting and airset casting all have their own sets of benefits and drawbacks. The right choice depends on the quantity being cast, the size of the part, and the requirements for dimensional accuracy, surface finish and material.

While it's not as widely used as shell molding or greensand casting, airset casting has plenty of advantages, and can be the perfect option for the right product.

Tags: Metalcasting, Eagle Alloy, Airset Casting

How Investment Casting Compares to Other Metalcasting Methods

Tags: Metalcasting, Processes, Investment Casting

Aluminum Casting vs. Steel Casting: Choosing the Right Alloy for Your Cast Products

In modern metalcasting, steel and aluminum are two contenders for the top material of choice. Thousands of manufacturers around the world rely on both metals to produce strong, light and corrosion-resistant metal parts and products.

You'll find hundreds of different grades and alloys for both steel and aluminum, and each has its specific advantages and disadvantages. For this comparison, we'll focus on differences between aluminum and steel alloys in general, rather than zooming in on differences between specific alloys.

Tags: Metalcasting, Machining, Aluminum Casting, Aluminum, Materials

Investment Casting Guide Ebook: New Eagle Group Resource for Manufacturers

Eagle Precision Cast Parts, Inc. just released a downloadable resource, titled Investment Casting Process Guide: A Comprehensive Introduction to Investment Casting.

The goal of the 21-page ebook is to make it easy for manufacturers, and anyone else who's interested, to learn the basics of investment casting. Manufacturers looking for a better way to produce parts can find information on tolerances, design recommendations and a full case study.

Tags: Metalcasting, Investment Casting, Eagle Precision, Investment Casting Guide

5 Mistakes Companies Make When Choosing a New Metalcasting Supplier

Whether you're bringing a new product to market, improving on an old design or entering the world of metal manufacturing for the first time, you'll need to find the right foundry for the job. Choosing a metal casting supplier can be a daunting task, and not everyone makes the right choice the first time.

These five mistakes companies make when choosing a new metal casting supplier can lead to expensive fixes, defective products, overpriced castings, logistical headaches and customer service nightmares. Read on to find out what NOT to do when choosing a new foundry.

Tags: Metalcasting, Supply chain, Suppliers

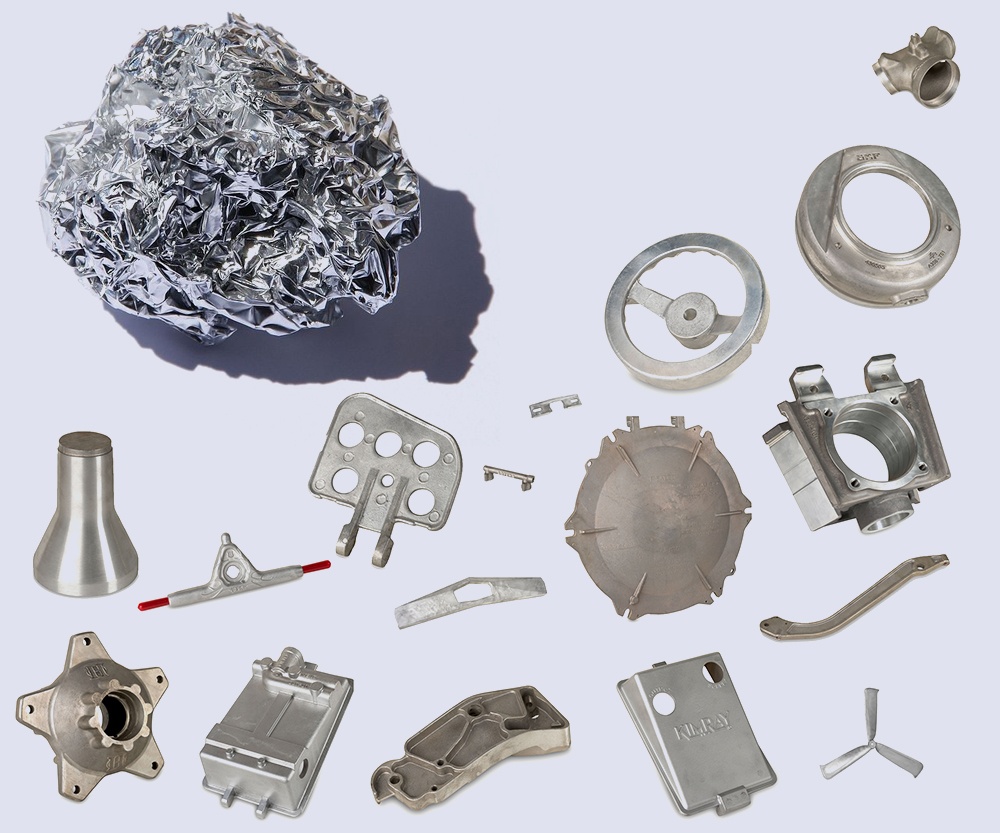

Casting Aluminum: Comparison of Methods

Aluminum can be shaped through a wide variety of process, including:

- Casting

- Extrusion

- Forging

- Rolling

For any type of metal, casting is arguably the most versatile of all of the forming processes, and results in the greatest variety of parts. In fact, the US Department of Energy estimates that over 90% of all manufactured goods contain metal cast products.

The same casting techniques used for other metals can be applied to aluminum, but some of the most popular methods used with aluminum are permanent mold casting, greensand casting and die casting.

Tags: Metalcasting, Processes, Aluminum Casting, Aluminum, Eagle Aluminum

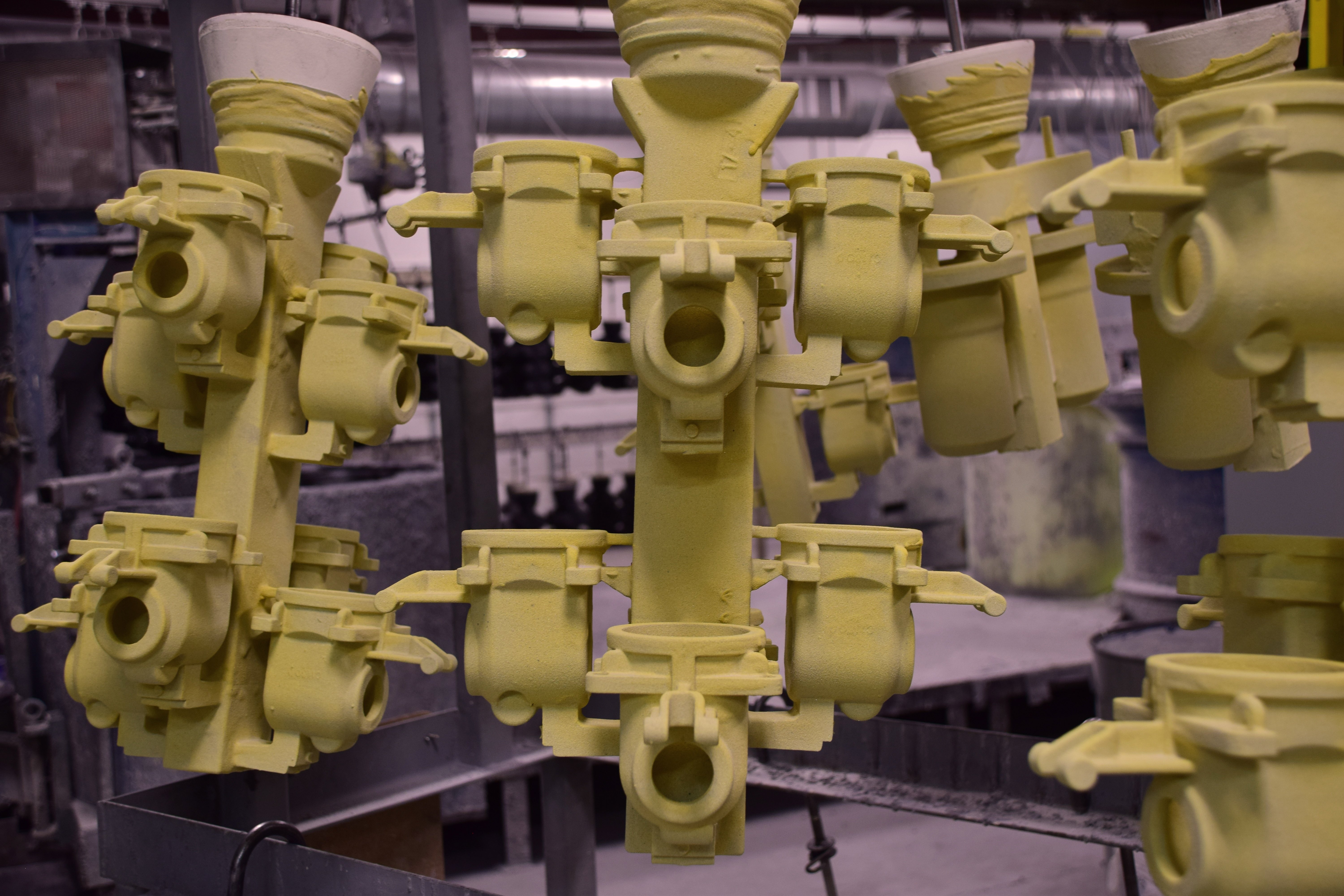

How the Investment Casting Process Works

Investment casting, sometimes known as lost-wax casting, is a metal forming method known for its ability to produce parts with tight tolerances, complex inner cavities and accurate dimensions.

As we discussed in our Introduction to Investment Casting post, the basic technique has existed for millennia. Over the years, innovations in equipment and methodology have kept pace with demand. Today, investment casting is one of the most popular forms of metal casting.

Read on to learn more about the unique process of investment casting.

Tags: Metalcasting, Processes, Investment Casting, Eagle Precision

Introduction to Investment Casting

Investment casting is nearly as old as metalcasting itself, with the earliest known examples dating back to 3,500 BC. Before investment casting was invented, metal castings were created using open stone or ceramic molds. Investment casting allowed for much greater detail and smoother finish, vastly expanding the possibilities of metal casting.

Today, investment casting is one of the most versatile methods of metal casting. The process, which is still similar to that used over 5,000 years ago, allows for tighter tolerances, more intricate shapes and smoother surface finishes than other metal casting methods.

Tags: Metalcasting, Processes, Investment Casting, History

Foundry in a Box: Bringing Metalcasting to the Classroom

Ask a group of 5th graders what they want to be when they grow up, and you'll get a long list of answers: firefighter, detective, athlete, musician, astronaut. These (and other top kids' dream jobs) are certainly vital to our society, but as proud and forward-thinking manufacturers, we have to ask: Wouldn't you rather be a metal caster, or a machinist, or a Six Sigma coach?

Maybe the answer is "yes," but the issue is that not many kids have been asked this question. That's where programs like Foundry in a Box come in. Dedicated professionals in the manufacturing industry visit schools and introduce students to the basics of metalcasting, and manufacturing careers, through hands-on projects. Programs like this not only expand students' horizons, but they're also vital to the future of manufacturing in the United States.

Tags: Metalcasting, Foundry in a Box, Education

How Shell Molding Compares to Other Metalcasting Methods

The shell mold process is unique and exhibits many advantages over other metal casting processes, but many people don’t fully understand its benefits.

In this installment of the Introduction to Shell Molding blog series, we will compare and contrast the shell mold process with investment casting and greensand casting methods. It is important to keep in mind that all processes have their own appropriate applications.

Based on your part's needs in terms of tolerances, production volume and surface finish, any one of these processes could be the ideal match.

Tags: Shell Molding, Metalcasting, Processes, Introduction to Shell Molding