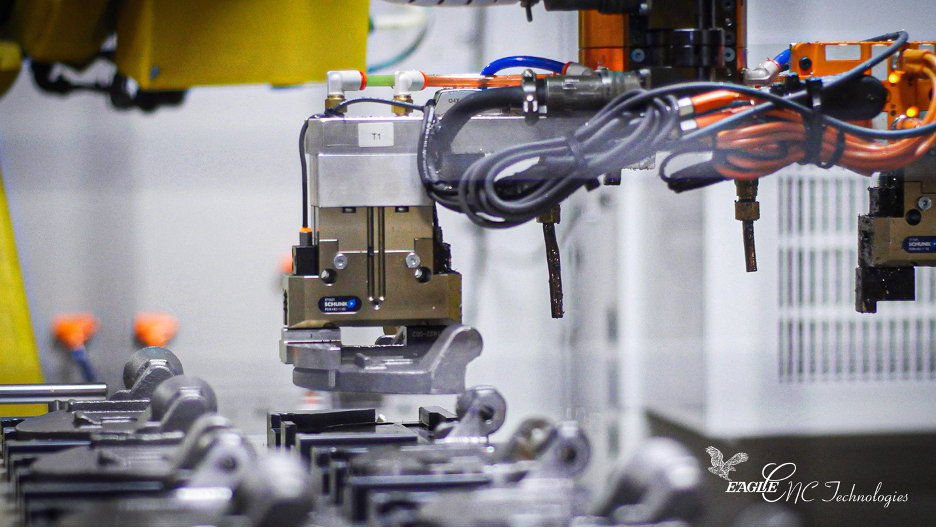

Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

Michigan Manufacturers Honor Veterans by Reviving a Sunken Patrol Boat

Collaboration Between Casting and Machining to Re-Engineer a Lost Component of a Vietnam-Era Patrol Boat

Muskegon-based manufacturers Eagle CNC and Eagle Alloy put their capabilities to the test when they set out to replicate a key component of a Vietnam-era patrol boat as a steel casting. For the team behind the casting, this project is about more than fixing a boat; it’s about preserving history, honoring the legacy of those who served and sacrificed, and ensuring their stories continue to be told for generations to come.

Tags: Eagle Alloy, CNC Machining, Eagle CNC, 3D Scanning, Reverse Engineering, 3D Printed Molding

Manufacturing Internships Are a Win-Win

How Eagle CNC’s internship program benefits students, the company and the industry as a whole

A version of this article was originally published in the research journal Modern Casting in its December 2024 issue.

In the hands-on world of manufacturing, textbooks alone can't provide the full picture—real-world experience is essential for developing expertise and encouraging innovation. For both students and manufacturing companies hoping to secure talented employees in the future, internships bridge the gap between classroom theory and hands-on application, pushing limits and enabling creative problem-solving. By integrating internships into their operations, manufacturing companies foster a continuous cycle of learning, adaptation and improvement that drives innovation forward in the industry. Eagle CNC is committed to shaping the next generation of manufacturing professionals by providing practical experience and fostering essential, real-world skills through its internship program.

Tags: CNC Machining, Eagle CNC, Employment, Students, Internships

Eagle CNC on the Rise

Just a year since being fully acquired by Eagle Alloy, the Eagle CNC team is showing their resilience and ability to thrive in their new environment

It’s been a year since Eagle Alloy fully acquired Eagle CNC, and a lot has changed. The companies are growing closer together in terms of shared systems and shared goals, and both are benefitting immensely. From improved efficiency on the shop floor to more streamlined scheduling, the partnership has opened up a world of opportunities for shared growth as a holistic, concept-to-completion manufacturing team.

Tags: CNC Machining, Eagle CNC

Bill Seyferth and Eagle CNC: A Career of Innovation in Michigan’s Manufacturing Industry

Bill Seyferth is the founder of Westech Corp., which now operates as Eagle CNC. In recent years, this state of the art machine shop has worked alongside Eagle Alloy and Eagle Precision as part of Muskegon’s Eagle Group, a manufacturing team providing casting-to-completion services for a variety of customers. As Bill retires from the company he founded, it is one of West Michigan’s largest machining facilities and carries out precision manufacturing work for Fortune 500 companies like John Deere and Caterpillar, along with a host of influential customers across a range of industries.

Tags: Eagle CNC

Eagle CNC Technologies Welcomes Jason Clark as New VP/GM of Operations

Eagle CNC Technologies (ECT) is thrilled to announce a new addition to our management team. Jason Clark has joined Eagle CNC as Vice President and General Manager of Operations, a position newly created to support the Eagle Group’s plans for growth.

With more than 27 years of manufacturing experience, Jason has spent his career supporting West Michigan manufacturing. After spending four years in the U.S. Navy performing avionic maintenance for electronic counter measures and comm/nav/radar on EA6B aircraft, he returned to Michigan to work in manufacturing. In 2001, and with experience at two prestigious automotive companies under his belt, Jason joined Port City Group, a Muskegon manufacturer. Here he began in metalcasting as a Quality Systems Manager in Port City’s die casting division, and steadily rose in the ranks to become General Manager for Port City as well as VP of Operations for Michigan Wheel.

Tags: Press Release, Eagle CNC, Employment

Heat Treatment in CNC Machining

In this article, we’ll discuss how experienced machine shops like Eagle CNC think about the complex relationship between heat treatment and machinability. Determining where heat treatment fits into the CNC machining process is a vital consideration for machining parts to net shape quickly and cost-effectively.

Eagle CNC is the Eagle Group’s state-of-the-art machine shop, specializing in CNC machining of both ferrous and nonferrous castings, forgings, bar stock and burn outs. At Eagle CNC, we machine new parts directly from raw stock, or from parts that have been shell cast or investment cast by our sister companies, Eagle Alloy and Eagle Precision. While our workpieces start in a variety of states, nearly every product we machine undergoes heat treatment before delivery.

Tags: CNC Machining, Eagle CNC, Metallurgy, Heat Treatment

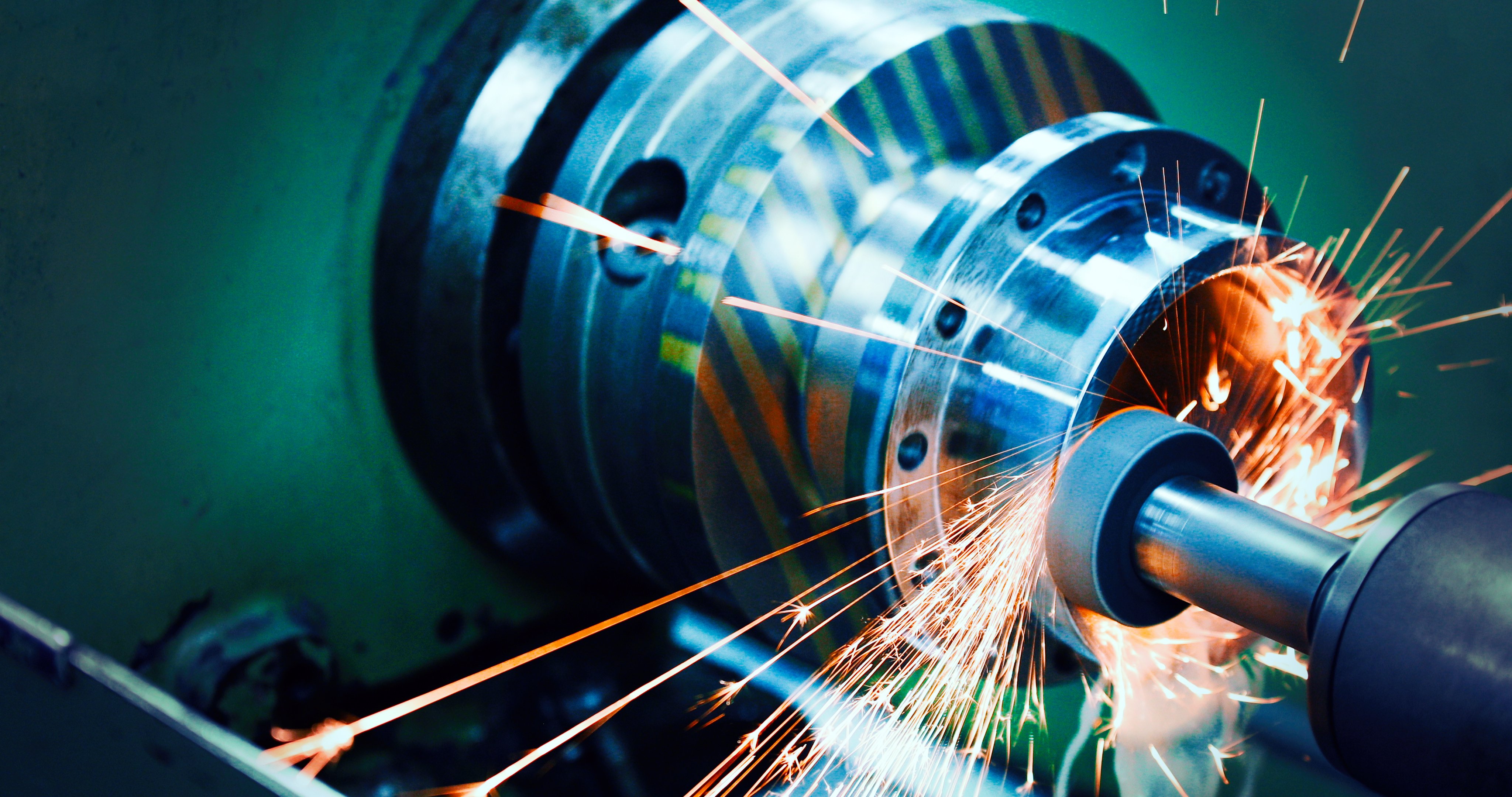

What Precision Machine Shops Do: Grinding

Grinding is a machining process using abrasive surfaces to remove material from metal workpieces. On the surface (pun intended) grinding may seem different than other machining processes, but it still works through chip formation and removal–just like sawing, milling, broaching and most other techniques. Grinding can produce surfaces conforming to rough or extremely close tolerances. Because of its versatility, grinding is used for simple gate removal in castings as well as advanced finishing processes like polishing and sharpening.

Tags: Processes, Machining, Eagle CNC, What Precision Machine Shops Do, grinding

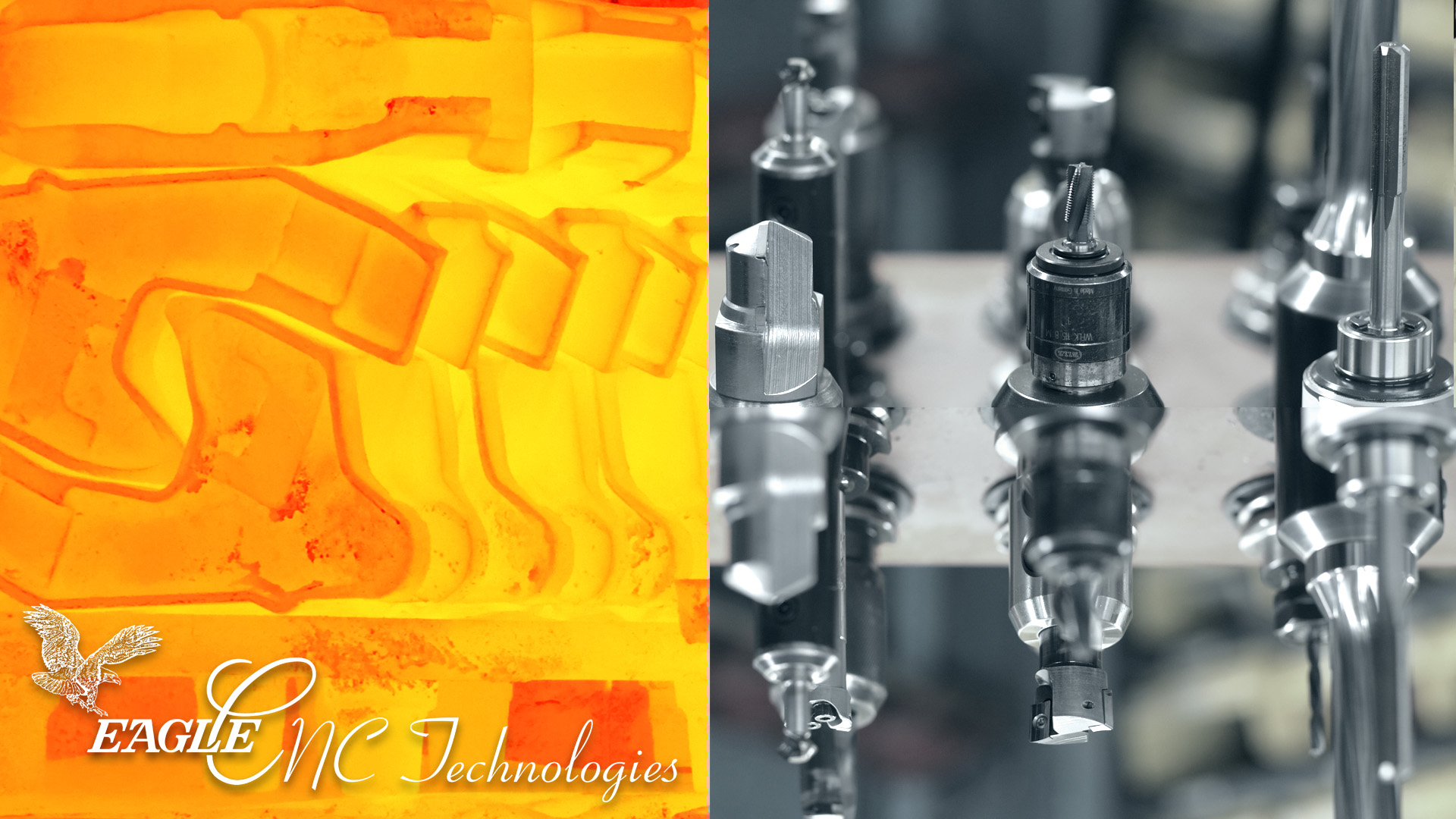

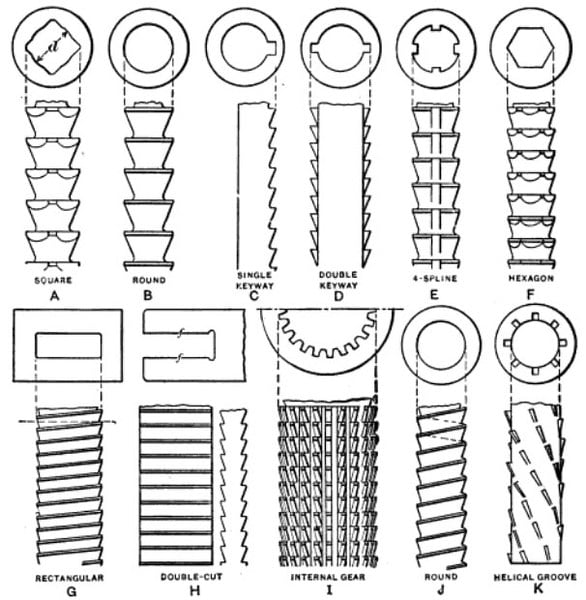

What Precision Machine Shops Do: Broaching

Broaching is a machining process using a cutting tool with teeth that increase in size from front to back. In many cases, an entire surface (or multiple surfaces) can be finished in a single pass with broaching. The technique is most often applied to finish holes, splines and flat surfaces.

Broaching is a relatively new machining process, developed in the 1850s with metal-specific applications. Originally, broaching was used to perform work on internal characteristics, like keyholes in pulleys and gears. During the 20th century, broaching was further developed for use in firearms, and subsequent developments have dramatically improved tolerances and made broaching more versatile for modern machine shops.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do, broaching

What Precision Machine Shops Do: Sawing

Sawing is one of the oldest cutting techniques in use today, and innovations have allowed the process to keep up with advances in material, tolerances and product complexity. By definition, sawing is cutting a narrow slit in a workpiece by moving a toothed or abrasive cutting tool against the surface. Sawing is often used to remove large sections of material without particular concern for tolerances, but modern CNC sawing machines can be used for finishing work as well.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do