What Precision Machine Shops Do: Boring

Boring may not sound like a very exciting topic, but don't let names deceive you: boring is one of the most widely used techniques in machining, and one of the most reliable ways to finish holes.

Boring is the process of enlarging and finishing pre-existing holes. The holes might have been cast, drilled or otherwise formed to a rough state, but boring is often the best technique to provide the accuracy and repeatability expected of CNC machined parts.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

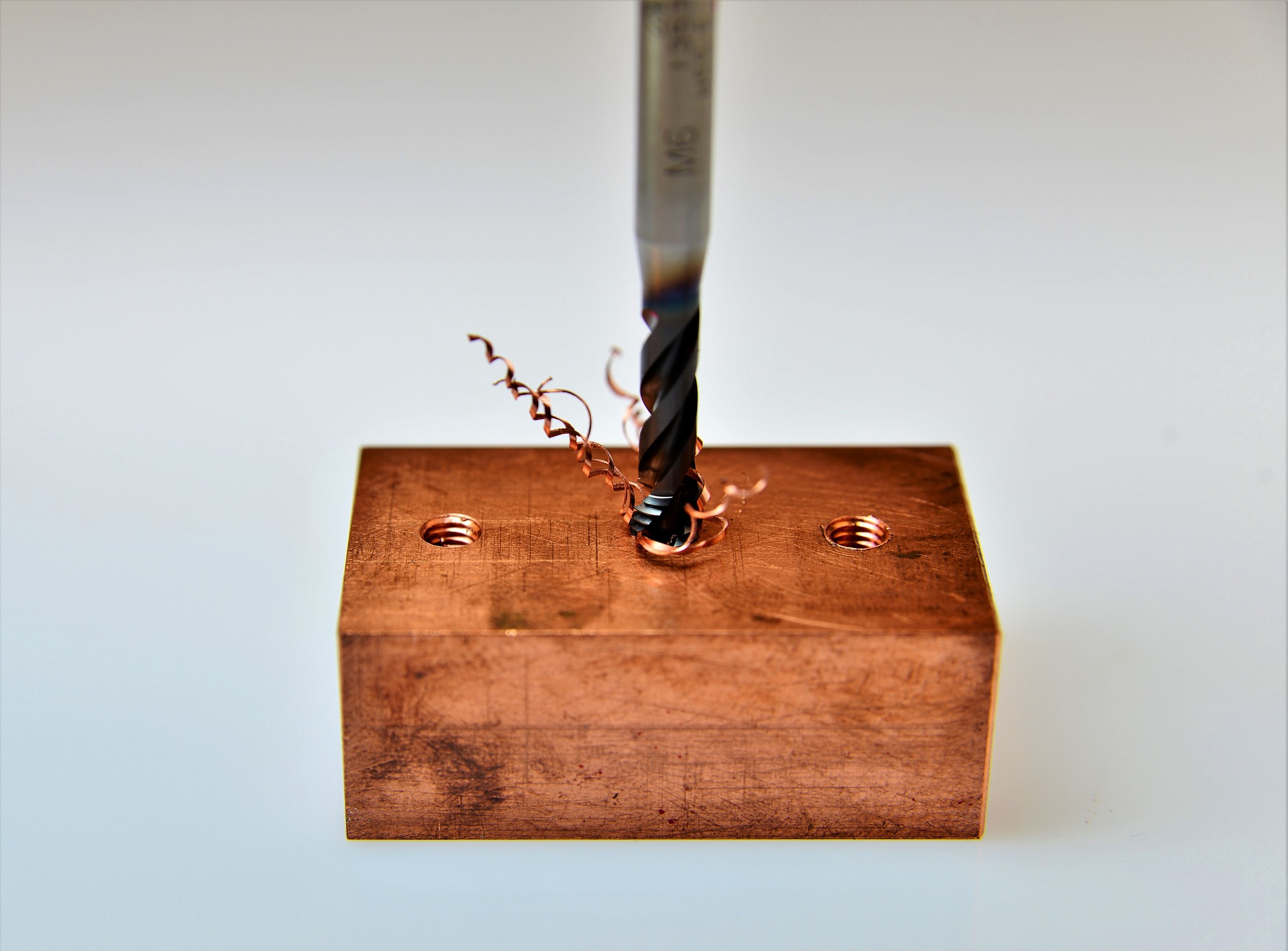

What Precision Machine Shops Do: Drilling

Drilling is one of the most common techniques used in manufacturing to create holes. In contrast to other hole-making methods like boring, reaming and tapping, drilling is most often used to create holes in unbroken surfaces. In precision CNC machining, drilling can range in scope from simple, rough hole drilling to complex, multi-feature hole drilling.

Tags: Processes, Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

What Precision Machine Shops Do: Milling

Milling is one of the most common processes in CNC machining, most likely because it is so versatile. Using a single tool, machine shops can create nearly limitless shapes on the surface of a workpiece. Milling can completely transform a piece of metal stock into a finished part of nearly any complexity.

The milling process in CNC machining consists of removing material with a rotating cutting tool. Unlike turning, the workpiece does not need to rotate in milling operations. In some cases, the workpiece will move linearly against a cutting tool; in other cases, the workpiece will remain stationary while the cutting tool moves.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Milling, What Precision Machine Shops Do

What Precision Machine Shops Do: Turning

Turning has been practiced by machinists for centuries on many different materials. Originally, turning acted on wood to create complex, cylindrical designs for use in tools, handles, furniture. Today, turning is a vital part of the metal manufacturing process, and a major technique used by precision CNC machine shops in the United States and around the globe.

Turning is the process of rotating a workpiece and bringing it into contact with a cutting tool. As the workpiece turns, the rotating motion forces the cutting tool to strip away material. The cutting tool itself can move linearly, either parallel or perpendicular to the axis of the spinning workpiece. Cuts made in turning, and the resulting shape of the workpiece, are determined by the motion and shape of the cutting tool.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Turning, Lathe, What Precision Machine Shops Do

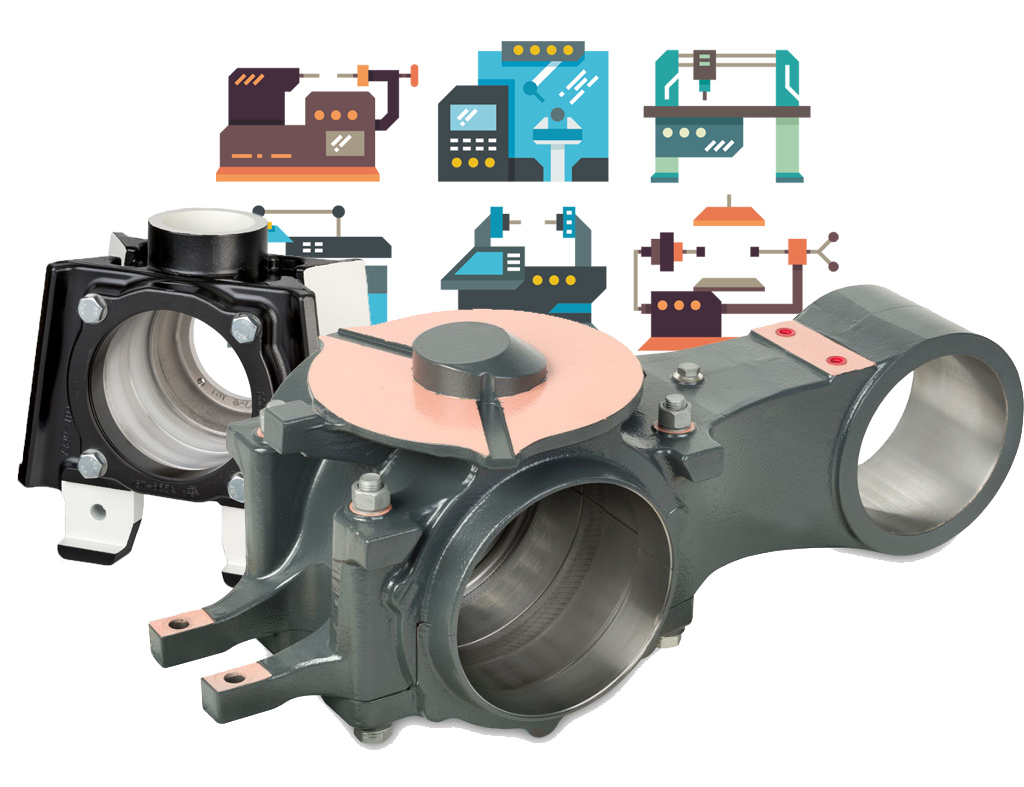

What Precision Machine Shops Do: Introduction

Our new blog series What Precision Machine Shops Do focuses on the processes, equipment and knowledge involved in modern machining. We'll take a close look at key metal removal techniques like milling, turning, facing, boring and tapping, along with the many products and parts that work as a result of these processes.

For the most part, we'll be discussing CNC machining, or Computer Numerical Control machining. For a brief introduction to CNC, explaining how it developed and how it differs from non-CNC machining, check out our Introduction to CNC Machining blog post.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

Introduction to CNC Machining

This article was updated on July 8, 2025.

CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again.

Tags: Machining, CNC Machining, Eagle CNC

Numbers Don't Lie: Eagle Companies Achieve Huge Improvements in 2017

Two Eagle Group companies, Eagle Alloy, Inc., and Eagle CNC Technologies, Inc., have posted a series of personal bests and significant improvements across the board.

As you can see below, Eagle Alloy's achievements in 2017 include:

- 96.4% delivery – 2nd best in company history

- 1.87% scrap – BEST in company history

- 2.64% returns – Best in last 10 years

- 97.4% audit score – Best in last 8 years

- .27 PPM resulting in complaints – BEST in company history

Tags: Eagle Alloy, Efficiency, Eagle CNC