Jeff Cook

Recent Posts

Casting Advocates: Get to Know SFSA

In our blog series, Casting Advocates, we explore the work of organizations and industry leaders who work to elevate the metalcasting profession. Here in this first installment, we focus on the Steel Founders' Society of America.

The Steel Founders' Society of America (SFSA) was first organized in 1902, and initial meetings were a "luncheon club" attended by a handful of casting companies from the Midwest and the East Coast. After more than a century of evolution, SFSA is now a major force in promoting metalcasting competitiveness industry-wide. Today, SFSA works to provide members with the tools and knowledge to succeed in today's high-tech manufacturing environment.

Tags: Education, Community, Casting Advocates, Trade Associations

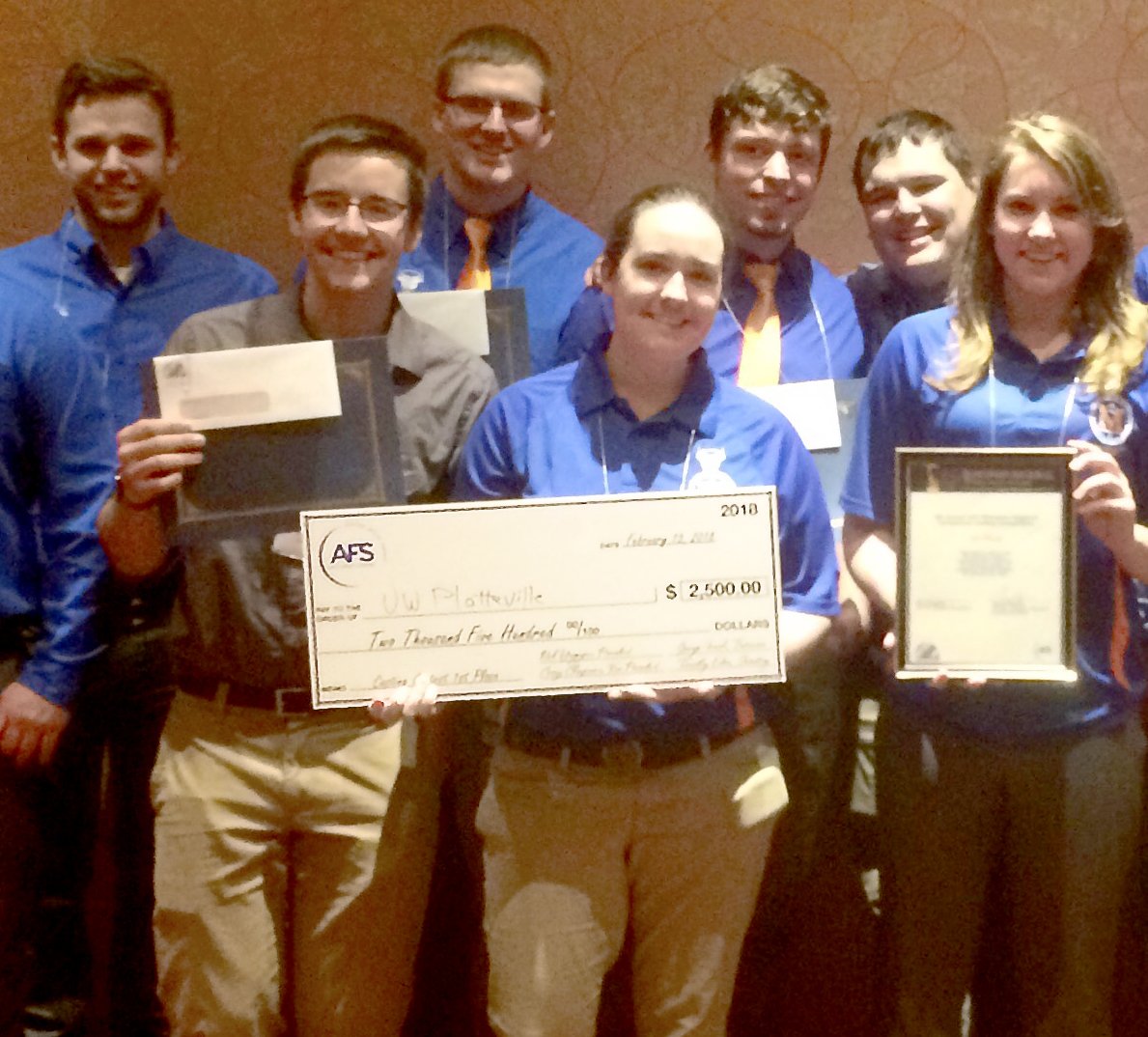

Coming Soon: AFS Regional Student Casting Competition

Forget about the Rose Bowl–this year's college competition to watch is coming up in February!

The AFS Wisconsin Regional Invitational Casting Competition will host casting teams from colleges and universities around the Midwest. Taking place during the AFS Wisconsin Regional Expo and Conference, the event invites student teams to present cast products they've created using school casting facilities. All projects in competition were completed by members of AFS student chapters.

Tags: Metalcasting, Students, Student Metalcasting Competition

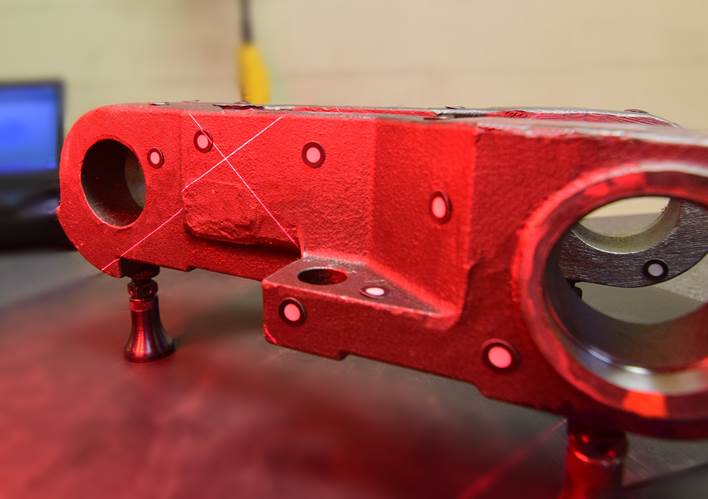

Case Study: Reverse Engineering Cast Products on an Expedited Timeline

Cem-Tec, a manufacturer of steel light poles in business since 1974, approached Eagle Alloy, Inc. with an emergency order. Due to an unforeseen supply-chain issue, they needed to find a new foundry to manufacture one of their popular products. With orders in and customers waiting, the clock was already ticking.

The following case study illustrates the steps Eagle Alloy followed to transfer casting of the product to our facility and to ensure that Cem-Tec had high-quality products ready for their customers as soon as possible.

Tags: Eagle Alloy, Case Study, Product Design, Development, Product Development

Manufacturing Day 2018 at Eagle Alloy: Event Recap

Eagle Alloy was lively and bustling on Thursday, October 4th. That's no surprise: our Muskegon, MI campus is regularly buzzing through three shifts a day, five days a week. But this particular day brought in a larger crowd than usual: in celebration of Manufacturing Day 2018 we opened our campus to local schools and community representatives for a demonstration of modern metalcasting.

The goal of Manufacturing Day is to inspire the next generation of manufacturers, and we wanted to support that goal any way we could. By inviting students to witness our work firsthand, we aimed to provide an introduction to modern metalcasting and manufacturing. After nearly 40 years in business, we understand the importance of letting young people know about the exciting potential of metalcasting careers.

Tags: Metalcasting, Education, Community, Manufacturing Day, Event

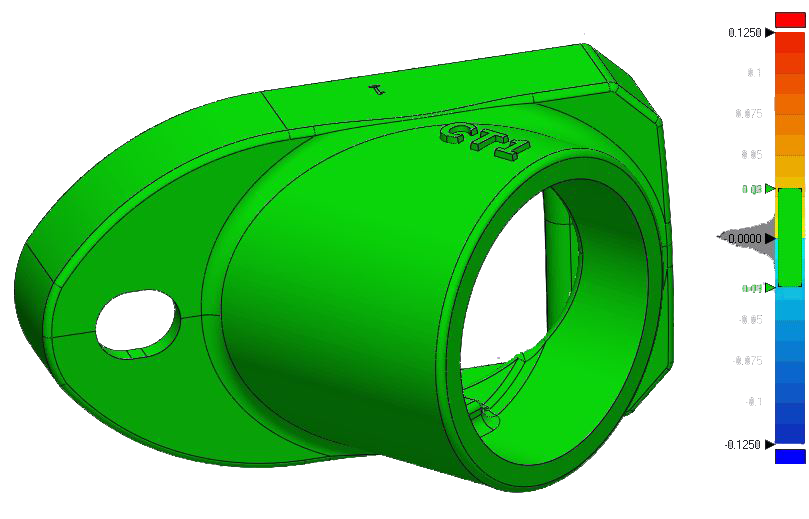

How Eagle Alloy's Handheld Laser Scanner Leads to Better Cast Products

Product development processes vary widely from foundry to foundry. The Eagle Group's Product Development blog series aims to highlight practices used by leading foundries that prioritize quality in every part they produce.

One product development practice that sets Eagle Alloy apart from other shell molding foundries is their use of a handheld laser scanner for inspection and dimensional reporting. This technology greatly improves the accuracy of dimensional reports, and makes it easier for customers to verify that new parts meet their requirements.

Tags: Metrology, Product Design, Development, Inspection, Product Development, Technology, 3D Scanning

Designing Cast Products: Starting the APQP Process with the Right Questions

APQP, or "Advanced Product Quality Planning," is a product-design process developed by automakers in the 1980s. Since then, a large number of businesses have adopted APQP for the product development stage.

A major portion of APQP is devoted to planning the production process, and making the right design decisions at an early enough stage to prevent expensive corrections later. When APQP is carried out correctly, it's a comprehensive and complete process. The foundry will engage the customer on multiple levels to learn everything they can know about the product, its end use and its working environment before finalizing design.

Tags: APQP, Product Design, Development, Product Development

Getting Started with Airset Casting

Every manufacturer bringing a cast product to market must decide on the right casting process to use. Casting methods like shell molding, greensand casting, investment casting and airset casting all have their own sets of benefits and drawbacks. The right choice depends on the quantity being cast, the size of the part, and the requirements for dimensional accuracy, surface finish and material.

While it's not as widely used as shell molding or greensand casting, airset casting has plenty of advantages, and can be the perfect option for the right product.

Tags: Metalcasting, Eagle Alloy, Airset Casting

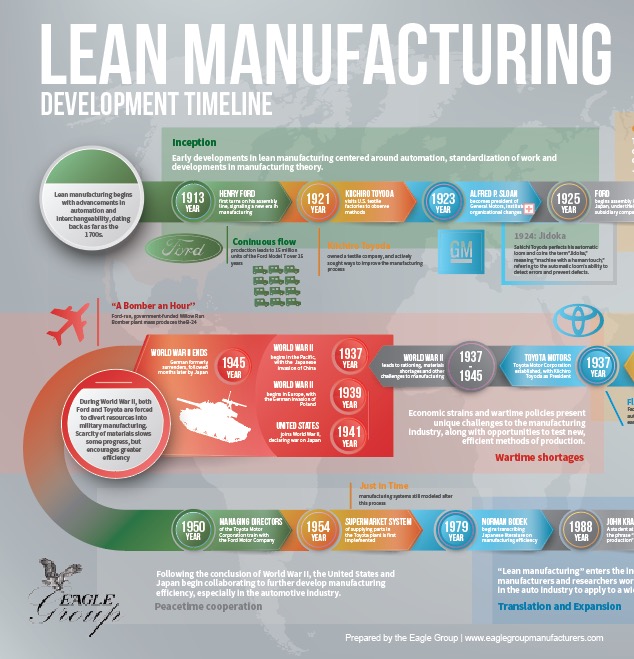

Infographic: Lean Manufacturing Timeline

The history of lean manufacturing dates back at least to the 1700s, when Eli Whitney developed interchangeable parts in order to deliver a massive order of muskets to the American Army.

It wasn't until 1988 that John Krafcik coined the phrase "lean manufacturing" in his research as an MIT student. For most of the 20th century, lean manufacturing was tied closely to industrial innovations in the United States and Japan. While it wasn't called "lean" for many decades, American and Japanese automakers laid the groundwork for the tools of lean manufacturing that we use today.

5 Mistakes Companies Make When Choosing a New Metalcasting Supplier

Whether you're bringing a new product to market, improving on an old design or entering the world of metal manufacturing for the first time, you'll need to find the right foundry for the job. Choosing a metal casting supplier can be a daunting task, and not everyone makes the right choice the first time.

These five mistakes companies make when choosing a new metal casting supplier can lead to expensive fixes, defective products, overpriced castings, logistical headaches and customer service nightmares. Read on to find out what NOT to do when choosing a new foundry.

Tags: Metalcasting, Supply chain, Suppliers

Case Study: Lean Manufacturing at Eagle Alloy

Eagle Alloy, Inc. was founded in 1979 and quickly grew from a short-run facility to a medium-to-high-production steel foundry. Despite the company’s success, its founders were not satisfied with the status quo. Having heard of developments in lean manufacturing, they decided to implement these tools in hopes of achieving greater efficiency, stability and quality throughout the production process.

5S: The Beginning

As with many production facilities beginning to experiment with lean manufacturing, Eagle Alloy started with 5S. 5S is easy to adapt to just about any environment, and the key to lean is customization. Every lean tool must be adapted to the particular type of production, to the size of the company and to the facility's space.

Tags: Lean Manufacturing, Eagle Alloy, Case Study