Jeff Cook

Recent Posts

Michigan Manufacturers Honor Veterans by Reviving a Sunken Patrol Boat

Collaboration Between Casting and Machining to Re-Engineer a Lost Component of a Vietnam-Era Patrol Boat

Muskegon-based manufacturers Eagle CNC and Eagle Alloy put their capabilities to the test when they set out to replicate a key component of a Vietnam-era patrol boat as a steel casting. For the team behind the casting, this project is about more than fixing a boat; it’s about preserving history, honoring the legacy of those who served and sacrificed, and ensuring their stories continue to be told for generations to come.

Tags: Eagle Alloy, CNC Machining, Eagle CNC, 3D Scanning, Reverse Engineering, 3D Printed Molding

Eagle CNC on the Rise

Just a year since being fully acquired by Eagle Alloy, the Eagle CNC team is showing their resilience and ability to thrive in their new environment

It’s been a year since Eagle Alloy fully acquired Eagle CNC, and a lot has changed. The companies are growing closer together in terms of shared systems and shared goals, and both are benefitting immensely. From improved efficiency on the shop floor to more streamlined scheduling, the partnership has opened up a world of opportunities for shared growth as a holistic, concept-to-completion manufacturing team.

Tags: CNC Machining, Eagle CNC

Keeping Castings Made in America: Supporting the American Foundry Industry through Entrepreneurship

The Eagle Group is a team of manufacturing companies based in Muskegon, MI, made up of three foundries and a machine shop. Eagle Alloy, Eagle Aluminum, Eagle Precision and Eagle CNC are connected through common ownership and through common goals: while each company occupies its own niche, they often work together to provide “concept to completion” manufacturing. Beyond these four companies, Eagle Group’s owners also have stakes in OEM companies that utilize the Eagle Group’s services, but occupy altogether different spaces in the manufacturing world.

Tags: Case Study

Miracle in Muskegon: How the Eagle Group Replicated a MiG 17F Fighter Jet Fuel Cap in Two Days

When a star jet pilot had a missing fuel cap at the Muskegon Air Show, the Eagle Group stepped in to replicate the part in less than 48 hours.

Wings Over Muskegon took place in July, 2023 at the Muskegon County Airport. This interactive aviation experience was a revamped version of the Muskegon Air Fair, and marked the first event of its kind held in Muskegon in 17 years. Spectators enjoyed aerial acrobatics, flybys from iconic planes like the B-52 Flying Fortress, and even rides in WWII-era planes and Vietnam-era helicopters. Our very own John Workman, Eagle Group co-chairman of the board, performed at the event with his formation flying team, the Hooligans.

Tags: Case Study

How a New Drum Blast Eliminated a Production Bottleneck

Eagle Alloy takes pride in our reputation as a world-class metalcasting facility, and we make sure every batch of castings is ready for the customer before it leaves our facility. In most cases, the final step before packing and shipping is blasting. The blasting process removes burrs, flash and other excess metal from cast parts and improves their overall surface.

Tags: Facilities, Equipment

Imagine a World Without Steel Casting Supply Issues

We don't have to say how good we are. Our customers do it for us!

Every six months, Eagle Alloy invites customers to fill out a survey rating their satisfaction with our services. We ask about every aspect of the supplier-customer relationship, from answering phone calls and emails to on-time delivery. Our company was founded in 1979 with a goal of providing high-quality castings and superior customer service; customer feedback is invaluable to us as we seek to better align our activities with our guiding principles.

Tags: Eagle Alloy, Testimonials

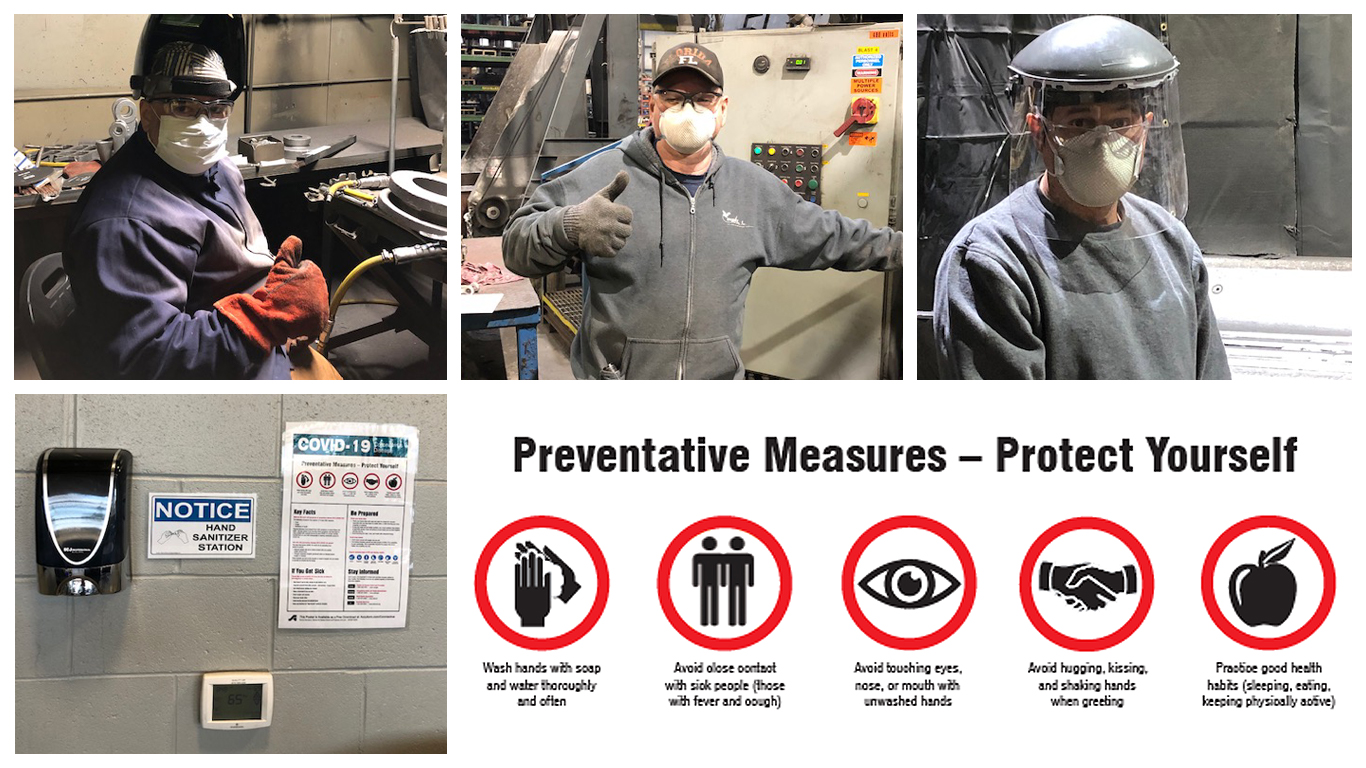

Staying Open Through COVID-19: Advice from an Essential Business

Operating as an essential business during the COVID-19 crisis is both an honor and a challenge. While Eagle Group companies have maintained continuous production, we have made a number of changes to our daily operations in order to maximize safety and clearly communicate new policies. Many of the lessons we've learned can be adopted by other manufacturing businesses as they prepare to reopen.

Tags: Coronavirus, COVID-19, Essential Business

The Eagle Group's Response to the COVID-19 Coronavirus

Eagle Alloy, Eagle Precision and Eagle CNC plan to maintain full production capability, even in light of the recent decision by Michigan’s Governor to close all “nonessential” businesses.

Tags: Coronavirus

Introduction to Metalcasting

This introduction to metalcasting provides a brief overview and history of the casting process, as well as an outline of common casting techniques in use today. The goal of this article is to give new manufacturers a better understanding of how metalcasting works and what steps are involved in producing cast products. By the end of the article, the reader should have a clear picture of the opportunities presented by metalcasting, and a sound appreciation for its potential as a modern manufacturing method.

Tags: Metalcasting, Processes, History

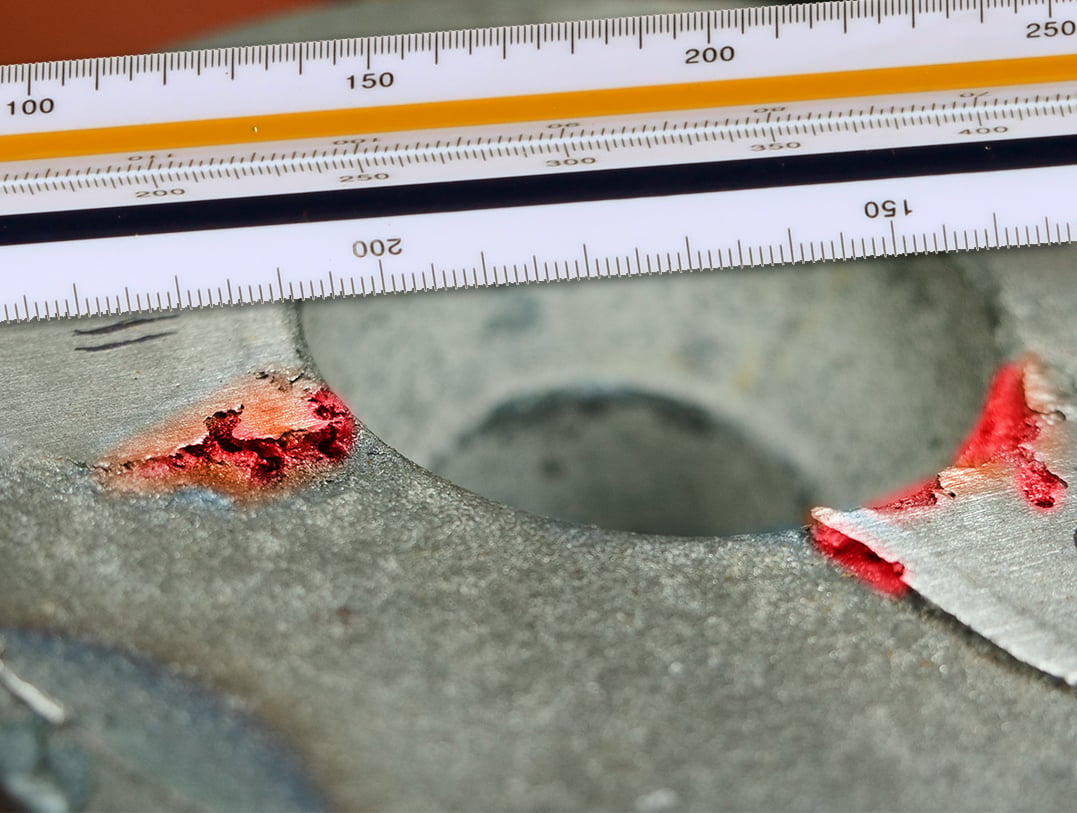

Understanding Casting Defects: When Is a Casting Returnable?

Metalcasting is a modern manufacturing industry, and cast products are utilized in 90% of durable goods, from lamp posts to space shuttles. Still, no casting is perfect. Even with recent innovations in simulation and process technology, nearly every cast product will contain some level of defect. A clear understanding of casting defects is vital for any casting customer, as it helps guide realistic expectations when working with a casting facility.

While experienced casting facilities are skilled in finding a balance between cost and quality, purchasers should be closely involved in determining admissible levels of defects in deliverable products.

Tags: Metalcasting, Casting Defects, Defects