Recent Posts

What Precision Machine Shops Do: Turning

Turning has been practiced by machinists for centuries on many different materials. Originally, turning acted on wood to create complex, cylindrical designs for use in tools, handles, furniture. Today, turning is a vital part of the metal manufacturing process, and a major technique used by precision CNC machine shops in the United States and around the globe.

Turning is the process of rotating a workpiece and bringing it into contact with a cutting tool. As the workpiece turns, the rotating motion forces the cutting tool to strip away material. The cutting tool itself can move linearly, either parallel or perpendicular to the axis of the spinning workpiece. Cuts made in turning, and the resulting shape of the workpiece, are determined by the motion and shape of the cutting tool.

Tags: Processes, Machining, CNC Machining, Eagle CNC, Turning, Lathe, What Precision Machine Shops Do

What Precision Machine Shops Do: Introduction

Our new blog series What Precision Machine Shops Do focuses on the processes, equipment and knowledge involved in modern machining. We'll take a close look at key metal removal techniques like milling, turning, facing, boring and tapping, along with the many products and parts that work as a result of these processes.

For the most part, we'll be discussing CNC machining, or Computer Numerical Control machining. For a brief introduction to CNC, explaining how it developed and how it differs from non-CNC machining, check out our Introduction to CNC Machining blog post.

Tags: Machining, CNC Machining, Eagle CNC, What Precision Machine Shops Do

Introduction to CNC Machining

This article was updated on July 8, 2025.

CNC Machining is often the last step in metal manufacturing, or sometimes the only process involved. Compared to other metalworking techniques, CNC machining is capable of meeting the tightest tolerances, and producing the most accurate, precise products over and over again.

Tags: Machining, CNC Machining, Eagle CNC

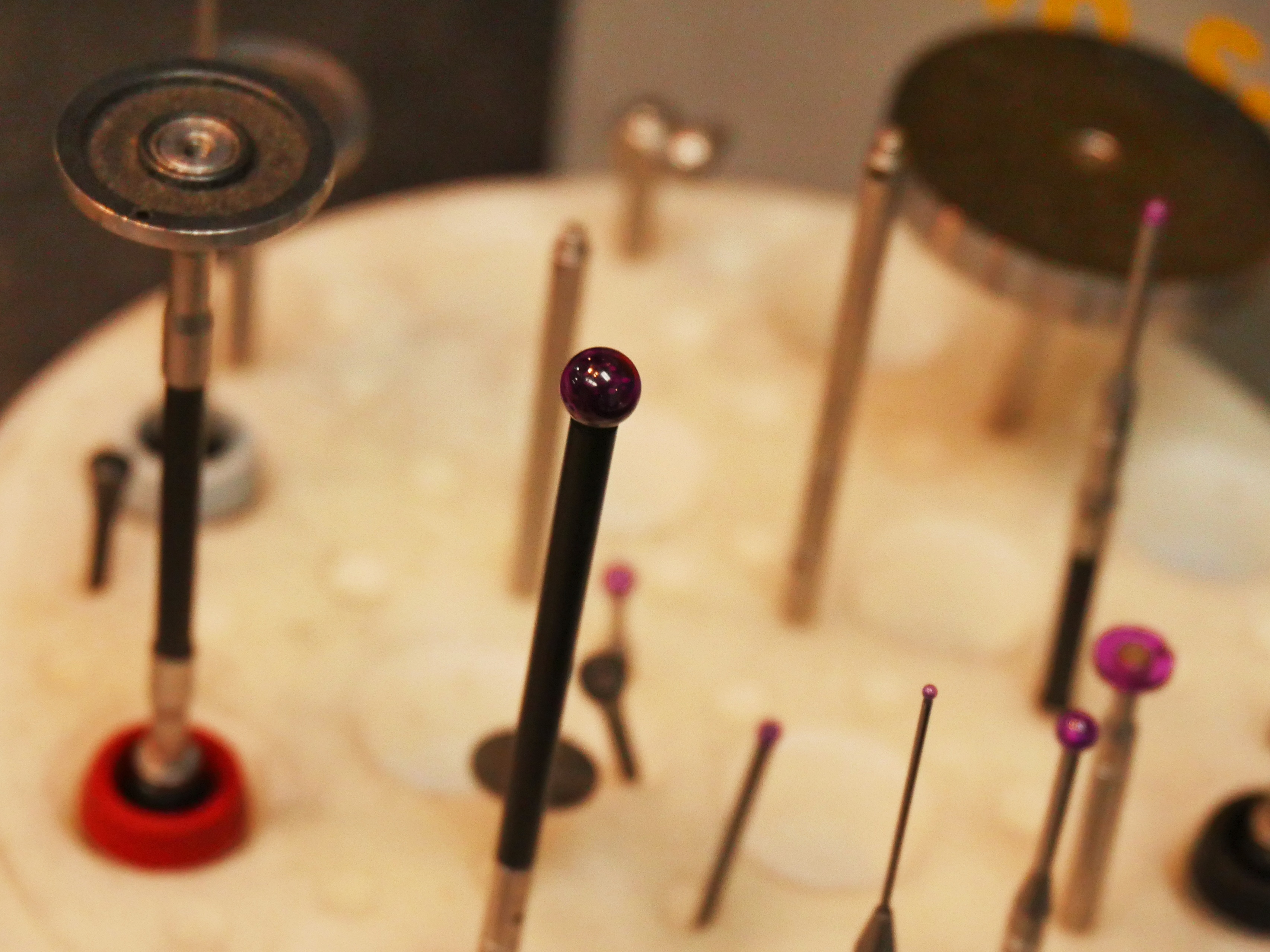

CNC Metrology: What Can a CMM Measure?

Coordinate Measuring Machines, known more often as CMMs, are a staple of industrial metrology. Of the thousands of variations of CMMs, you're likely to encounter at least one version in every manufacturing quality control department. You might not recognize it at first because CMMs can look like, well, pretty much anything–but in any form, these hard-working machines allow manufacturers to accurately measure a long list of product characteristics.

Sure, manufacturers could still measure their products the old fashioned way–with a good set of calipers and a lot of trigonometry–but in today's competitive environment, we need to take measurements in minutes, not days. We also require superior accuracy, sometimes down to .00005".

Tags: CNC Machining, Metrology

Measuring Standards: From Pharaohs' Forearms to the Speed of Light

Modern manufacturing wouldn't be possible without rigorous standards of measurement, along with sophisticated tools and techniques to help us measure tools, workpieces and finished products.

CNC machining is a prime example of the practical uses of modern measuring, or metrology. In metal-based manufacturing, CNC machining is often the last process before a part is delivered. Without incredibly accurate and precise ways to measure and cut, many of the metal products we take for granted would be impossible to produce.

The history of measurement is the story of how human civilization strove to find new ways to measure accurately, and it all leads up to modern metrology.

Tags: Machining, CNC Machining, Metrology, History

9 Ways to Improve Manufacturing Efficiency

This article was updated on July 10, 2025.

Efficiency is good for any business. It doesn’t matter if your company is manufacturing or service oriented. Greater process efficiency always offers a wide range of benefits over "business as usual."

On a broad level, manufacturing more efficiently can help cut costs, improve throughput and reduce environmental impact. All of these general benefits lead to additional benefits down the road, from increased sales and quality to improved company image.

Read on for 9 ideas to improve manufacturing efficiency.

Tags: Lean Manufacturing, Processes, Manufacturing, Efficiency

7 Essential Metrology Tools for Modern CNC Machine Shops

Metrology is the science of measurement. In CNC machining, principles of metrology need to be applied throughout the production process to ensure that each part is machined to the right size and shape, in accordance with specified tolerances.

It’s simple enough to take a ruler or a measuring tape and mark out inches or millimeters. But measuring dimensions of CNC machined parts – many with tolerances tighter than +/- .001 inch – is a whole other ball game. When you’re dealing with measurements that small, you need to have sophisticated measuring tools, and the knowledge to use them.

Tags: Machining, CNC Machining, Metrology