Eagle CNC Brings Next-Level Automation to West Michigan Manufacturing

Eagle CNC’s West Michigan machine shop provides some of the highest-precision machining available, but the meaning of precision in machining is constantly changing.

Industries across the board are calling for increasingly complex parts that challenge traditional machining methods. For a manufacturing job shop like ours, staying competitive means getting ahead—especially in terms of adopting new equipment and optimizing processes. Agriculture, construction, material handling, recreation, transit, utility, and offshore—these are just a few of the sectors we serve. Looking forward, we know the complexity of manufacturing projects for these industries will only grow.

At the same time, we’re seeing an emergence of new, local manufacturing facilities looking for reliable suppliers in their neighborhood: the uptick in demand for CNC machining in the Midwest has been palpable, and we’re even seeing increased demand for locally sourced products right here in our hometown of Muskegon, Michigan. These companies want the same high level of quality, but they need it fast. By investing in advanced CNC automation, Eagle CNC is improving not just accuracy, but efficiency—enabling rapid setup, reduced lead times, and the flexibility to meet urgent local demand.

Our latest CNC investments are about precision and speed. We’re equipping our shop to serve both ends of the spectrum—ultra-precise, complex machining for demanding industries, and quick turnaround, high-quality production for the growing base of local manufacturers who need parts now.

What’s New at Eagle CNC Technologies

Eagle CNC boasts a robust lineup of advanced machining equipment that reflects our commitment to precision, versatility, and volume variability (as well as high-volume capacity). Inside our 60,000-square-foot facility, you'll find a full range of horizontal and vertical mills, multi-axis mill/turn centers, and high-performance horizontal lathes. This diverse equipment portfolio enables us to meet challenging projects with ease, from prototyping to full-scale production runs.

Our average lead time is about 5 weeks, with optional expedited delivery. Which materials do we handle? Just about anything our customers throw at us, no matter how special or difficult the alloy’s profile may be.

And if you’re wondering if we supply parts to your industry, the answer is yes. Eagle CNC supplies to dozens of industries, including automotive tier 3.

Below, we want to highlight four new machine systems that we’ve recently added to our lineup: two are advanced machines equipped with robotic cells that amplify quality and reduce part time, and two are heavy-hitting standalone cells made to process the most dimensionally demanding jobs.

Okuma 2SP-2500H with Robotic Cell

The Okuma 2SP-2500H is a twin-spindle, dual-turret CNC lathe ideal for high-volume production of parts with rotational symmetry, like flanges. It uses an automated gantry system (a gantry is a structural framework that allows the tool to move precisely over a stationary workpiece) to load, flip, and transfer parts between two spindles. The gantry system keeps production moving by automatically handling parts between spindles. Raw pieces are picked from a stack, loaded, flipped as needed, and transferred through both machining operations without pause. Finished parts are unloaded while new ones are queued up, creating a seamless cycle.

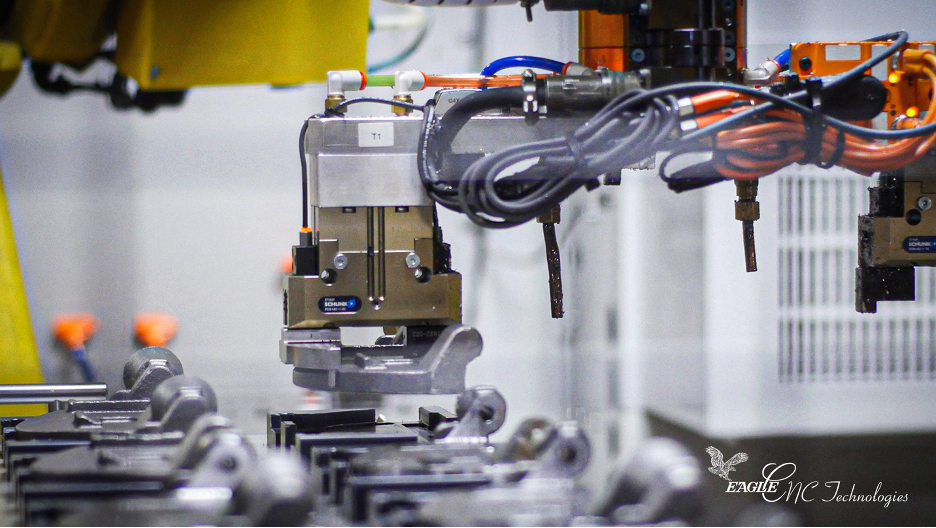

The Robotic Component

We’ve synced up a Fanuc articulated robot arm with Okuma’s inbuilt automated CNC process. The robot transfers a finished CNC-machined part to a hydraulic press where a bearing race is pressed in to finish off the part. The robot then moves the part to an inspection station where a Keyence-powered vision system checks it against dimensional tolerances. Approved parts are placed in the finished carousel, and all this is completed in under half the time it takes the CNC machine to produce a new part.

The Okuma 2SP-2500H is ideal for any round component up to 15 inches in diameter—whether it starts as a casting, forging, or bar stock—making it perfect for symmetric parts. Thanks to its pairing with a robotic cell, the Okuma is ideal for large volume runs, generally between 3,000-15,000 parts per month.

Haas UMC-500ss with Robotic Cell

The Haas UMC-500SS Mill is a 5-axis machining center used for precise multi-face machining, capable of producing complex geometries up to 20 inches long and 15 inches tall. Intricate details and multiple machining angles are no problem for the 500SS, which is designed for maximum versatility.

One of the complex parts machined to completion in the Haas is Hydrant Guard’s dual-plate valve system. These plates are key parts of an overall assembly that is designed to prevent water loss after a hydrant shear—a vital water-saving technology in water-scarce regions. Their performance in the field depends on the type of precision manufacturing the Hass can provide.

The Robotic Component

The robotic cell attached to the Haas performs a highly coordinated sequence of actions to load and unload parts from a CNC machine. Instead of an operator manually swapping raw and finished pieces, the robot pulls new parts from a drawer, flips them into the right position, and places them into the CNC machine. It also removes half-finished and finished parts, blasts fixtures clean with air, and makes sure everything is clamped securely before machining begins. This process keeps parts continually running with almost no downtime.

Like the Okuma, the Haas’s robotic pairing makes it ideal for high-volume production runs, generally anywhere between 3,000-15,000 parts per month.

By automating part movements on the Okuma and the Haas, we see boosts in efficiency and safety, and our operators are freed up to focus on other tasks. Both the robotic arms used with the Okuma and the Haas are manufactured by Fanuc, an industry leader in robotics, and the systems are installed and calibrated by West Michigan’s robotics experts, Mission Robotics.

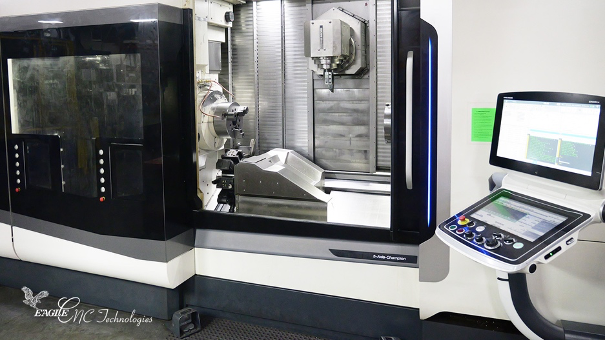

DMG Mori NTX 2500

The DMG Mori NTX 2500 is a high-precision mill-turn machine built for producing complex parts in a single setup. With advanced turning and 5-axis milling, it handles tight tolerances and multiple operations efficiently. Its dual spindles enable simultaneous machining on both ends of a part, potentially halving machine time for the right parts. A robust gantry loader paired with engineered thermal stability make it ideal for high-volume production, even with tough materials like stainless and alloy steels.

The DMG Mori NTX 2500 excels with larger castings up to 30 inches in diameter, perfect for parts requiring turning on both sides as well as mill work in the middle.

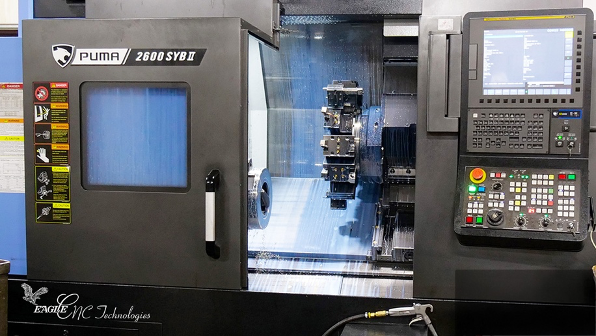

DN Solutions PUMA 2600SYB II

The DN Solutions PUMA 2600SYB II is like a Swiss Army Knife: rigid, reliable, and capable of performing multiple functions on a single part. It’s equipped with a Y-axis, sub-spindle, and live tooling for full-featured machining in one setup. The machine delivers reliable performance across both high-mix and high-volume runs.

Eagle CNC President Jason Clark understands the importance of versatility in machining: “When you eliminate setups, you're removing the risk of screwing up the first cuts, taking it to the next fixture and having it misaligned. The goal is to do as much as you can in one machine.”

Our PUMA is especially effective for machining valve bodies, using high-speed rotation to shape parts with precise, symmetrical accuracy.

Robotics and Automation in CNC Machining: A Strategic Investment

Investing in robotics and automation isn’t just about adding new equipment—it’s about laying the groundwork for long-term success. CNC equipment investments require significant amounts of capital, and it's critical to invest properly in planning, integration, and expertise. Getting it right the first time means fewer delays, smoother operation, and a faster return on investment.

For our recent robotic integrations, we’ve been working with Mission Robotics, a custom automation integrator located just south of us in Holland, MI. Their consultants helped us design, build, and program our Okuma 2SP-25000H and Haas UMC-500ss cells, everything from spec’ing out requirements to machine selection and cell design. According to Alex Snyr of Mission Robotics, “We rely on our customers, they're the expertise in machines, but we're also the experts in automation.” It’s key for CNC machining facilities and robotics consultants to take a collaborative stance. It also helps that they’re right down the road, and offer 24/7 support, in case anything goes wrong during production.

What Eagle CNC Upgrades Mean for Customers in West Michigan and Beyond

Automation and advanced CNC technology are delivering real benefits to our customers. Our processes are more consistent and reliable, ensuring that our customers receive the same high-quality parts every time. Automation allows our machines to run around the clock, which means faster turnarounds and quicker delivery for your critical projects.

As our capacity grows, we're equipped to handle everything from low-volume prototypes to high-volume production runs. This flexibility means we’re better positioned to serve OEM partners who are looking to source locally and reduce supply chain risk. Whether you're scaling up or refining your product, we're here to help you move faster and smarter.

“Automation doesn’t seem to be going away anytime soon,” notes Alex. On the contrary, automation is forming a new foundation of competitive machining. Much of this momentum is a direct response to the widening skills gap across the manufacturing sector. As younger generations explore different career paths and the pool of experienced machinists shrinks, the importance of strategic automation only grows.

At Eagle CNC, our approach is thoughtful and deliberate: we took a page out of Mission Robotics’ handbook by looking at the “3D” jobs—dull, dirty, and dangerous—before deciding whether to automate. That kind of intentional investment in both people and technology ensures we’re not just adding machines. Rather, we’re building a resilient operation that delivers real, measurable value to our customers. We’re also increasing job appeal to the next generation of machinists, which is a core part of the Eagle Group’s goal of keeping American manufacturing strong for generations to come.

In today’s market, automation is no longer optional for CNC machining facilities. It’s essential—and we’re proud to be leading that charge right here in West Michigan, throughout the Midwest, and beyond.

Tags: American Manufacturing, CNC Machining, Metrology, Eagle CNC, Technology, Facilities, Equipment

Written by Ryan Falkowski

Ryan Falkowski is sales and customer-service manager at Eagle CNC. He has been with the company since 2011.