What Is Shell Molding?

In this blog series, Introduction to Shell Molding, we’ll tell you everything you need to know about shell mold casting, from history to process and beyond. Whether you’re a student, a manufacturing professional, or just curious, this blog series will answer that burning question: What is shell molding?

Shell Molding (in a Nutshell)

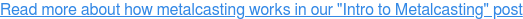

Shell molding, also known as shell mold casting or the Croning process, is a form of metal casting dating back to the middle of the 20th century. Compared to previous metal casting techniques, shell molding is able to produce more complex parts with a higher degree of precision. Shell mold casting is often lumped in with more common processes, like greensand casting, but it’s really not the same thing (more on that later, in the comparisons post).

Background and History

As you may have guessed from its nickname, shell mold casting was invented by a person named Croning. Specifically, Johannes Croning, a German engineer and businessman, invented the process in 1944. Mr. Croning financed the start of his foundry business by selling patents to American companies in the late 1920s. He was still working in Germany toward the end of World War II when he invented the Croning process.

As you may have guessed from its nickname, shell mold casting was invented by a person named Croning. Specifically, Johannes Croning, a German engineer and businessman, invented the process in 1944. Mr. Croning financed the start of his foundry business by selling patents to American companies in the late 1920s. He was still working in Germany toward the end of World War II when he invented the Croning process.

In 1947, American intelligence agents traveled to Germany to meet with Mr. Croning and discuss his innovation. They returned with a detailed report that allowed American manufacturers to further develop and utilize the new process. Throughout the 1940s and 1950s, American (as well as German) foundries worked to perfect both the process and the machines involved. By the late 1950s, shell mold casting was already producing a wide variety of sleek, strong parts in foundries around the world.

While the tools involved have changed–the introduction of robots, for example–the process has changed very little. Modern shell molding foundries, like Eagle Alloy in Muskegon, MI, still use the same tried and tested methods first employed by Johannes Croning.

Next up, we’ll go over some important terms you’ll need to know before you dive into the world of shell molding.

Tags: Shell Molding, Metalcasting, Processes, Eagle Alloy, Introduction to Shell Molding

Written by Jeff Cook

Jeff Cook is Chief Sales and Marketing Officer for Eagle Alloy in Muskegon, MI. While enlisted in the Marine Corps Reserves, he began working at Eagle Alloy in 1986 as a snag grinder on 3rd shift after his father told him to “Get a job!” Jeff is past President of the American Foundry Society. His passions include educating young people on the careers and advancement available in the metalcasting industry.